Cable aéreo

cable aéreo puede integrar la electricidad generada por sistemas de energía solar en la red. ZMS puede proporcionar los cables aéreos necesarios, como ACSR., ABRE, CAA, y AAAC para diversos proyectos de generación de energía fotovoltaica.

En sistemas de energía solar conectados a la red, El tipo de cable aéreo utilizado depende de los requisitos de instalación específicos., como el nivel de voltaje, capacidad de carga de corriente, resistencia mecánica, y condiciones ambientales.

Desde cables de CC utilizados para paneles solares hasta cables de CA utilizados para la salida del inversor, y finalmente a los cables aéreos o subterráneos que se conectan a la red., El equipo profesional de ZMS considerará exhaustivamente la escala del proyecto solar., ubicación geográfica, condiciones ambientales, y requisitos de conexión a la red para adaptar la solución de cableado eléctrico más adecuada para usted.

CAA (Todo conductor de aluminio)

Estructura:

AAC se compone de uno o más hilos de alambre de aluminio.. Estos conductores están hechos de aluminio refinado electrolíticamente con una pureza mínima de 99.7%. La construcción sigue las normas EN. 60889 Tipo AL1 según BS 215.

Características:

Los conductores AAC son altamente conductores y se utilizan principalmente en áreas urbanas para baja, medio, y líneas aéreas de alta tensión donde los tramos son cortos. Presentan una excelente resistencia a la corrosión., haciéndolos ideales para las regiones costeras.

Estándares:

ASTMB 230, ASTMB 231, TS IEC 1089, DIN48201, y BS 215.

AAAC (Todo conductor de aleación de aluminio)

Estructura:

Los cables AAAC consisten en alambres de aleación de aluminio trenzados concéntricamente. Están hechos de una aleación de aluminio tipo magnesio-silicio. (aleación 6201) con un contenido de magnesio entre 0.6-0.9% y contenido de silicio entre 0.5-0.9%. Estos conductores están diseñados para ser altamente conductores con un mínimo de 53% SIGC.

Características:

Los conductores AAAC ofrecen mayor resistencia, peso, y propiedades eléctricas en comparación con AAC y ACSR. Tienen mejores propiedades de tracción vertical y mayor resistencia a la corrosión., haciéndolos adecuados para líneas de transmisión de media y alta tensión.. Sus menores cargas para romper el hielo son ventajosas en regiones con bajas cargas de hielo y viento.. Los conductores AAAC se pueden personalizar según las necesidades de aplicaciones específicas y los requisitos del cliente..

Estándares:

ASTMB 230, ASTMB 231, TS IEC 1089, DIN48201, y BS 215.

ACSR (Conductor de aluminio reforzado con acero)

Estructura:

Los conductores ACSR constan de varios conductores de aluminio y acero galvanizado trenzados en capas concéntricas.. El núcleo está fabricado en acero galvanizado., que puede consistir en 1, 7, o 19 alambres, y está rodeado por hilos de aluminio. El cable central para ACSR está disponible con clase A, B, o galvanizado C.

Características:

Los cables ACSR son versátiles y adecuados para líneas de transmisión en todos los niveles de voltaje., incluyendo terrenos desafiantes como ríos y barrancos. Ajustando las proporciones de aluminio y acero., Se pueden lograr propiedades específicas para diversas aplicaciones.. El aumento del contenido de acero mejora las propiedades antiestáticas., mientras que un mayor contenido de aluminio aumenta la capacidad de carga actual.

Estándares:

ASTMB 230, ASTMB 231, TS IEC 1089, DIN48201, y BS 215.

Productos de cables ZMS

Preguntas más frecuentes

¿Qué cable aéreo utilizar en sistemas de energía solar??

En sistemas de generación de energía fotovoltaica conectados a la red, una vez que el inversor convierte la energía de CC generada en energía de CA y la integra en la red de CA, La transmisión de energía se realiza a menudo a través de líneas aéreas.. Típicamente, El proceso de conexión a la red de sistemas de generación de energía fotovoltaica puede ocurrir en los siguientes escenarios.:

Conexión directa

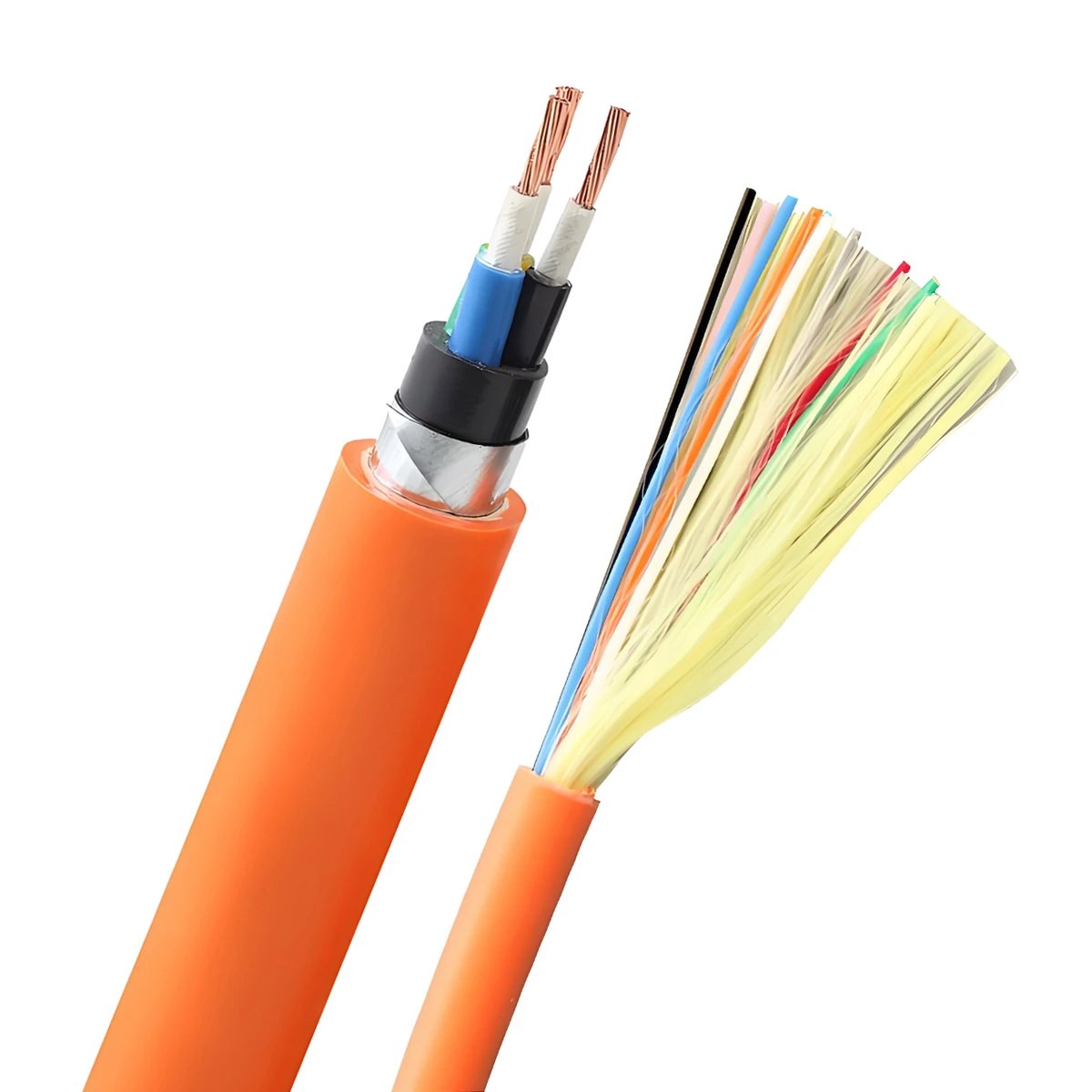

Para pequeños sistemas de generación de energía fotovoltaica distribuida, como la energía fotovoltaica en tejados residenciales, La energía CC se puede convertir directamente en energía CA a través del inversor y luego conectarse a la red de bajo voltaje a través de líneas de distribución.. En este caso, cables subterráneos de baja tensión y Cables aéreos aislados como cables ABC. se puede utilizar.

Conexión a través de Transformadores de Caja o Integración de Subestaciones

Las centrales fotovoltaicas de mediana o escala comercial podrán utilizar subestaciones tipo caja (transformadores de caja) para convertir la energía CC generada en energía CA adecuada para la integración en la red a través del inversor, y luego aumente el voltaje a través del transformador de caja para que coincida con el nivel de voltaje de la red aérea, antes de conectarse a líneas aéreas.

Las centrales fotovoltaicas montadas en tierra a gran escala normalmente requieren un transformador para aumentar el voltaje a un nivel más alto para una transmisión eficiente.. En este caso, La energía está conectada directamente a una subestación., que luego lo distribuye a las redes aéreas de alto o ultra alto voltaje..

En estos dos escenarios, si la distancia desde la central eléctrica hasta el punto de conexión a la red es relativamente corta y la carga no es grande, cable CAA podría ser una opción económica. Para medias distancias o donde se requiera un mejor rendimiento físico, AAAC cable puede ser una mejor opción. Para transmisión a larga distancia o donde se necesitan requisitos especiales de resistencia del cable, especialmente cuando las líneas aéreas necesitan cruzar terrenos complejos o soportar condiciones climáticas extremas, Conductor ACSR será la elección más adecuada.

¿Cuáles son las diferencias entre CAA?, AAAC, y cables ACSR?

CAA: Conductor totalmente de aluminio (CAA) Los cables son relativamente baratos., ligero, y tener buena conductividad, haciéndolos adecuados para transmisión de corta distancia y condiciones de carga ligera. Sin embargo, su fuerza es relativamente baja, con capacidad de tracción limitada, que podría no ser adecuado para largas distancias o situaciones que requieran una alta resistencia mecánica.

AAAC: Comparado con CAA, Conductor de aleación de aluminio (AAAC) Los cables tienen mayor resistencia mecánica., mejor resistencia a la tracción, y resistencia a la corrosión manteniendo una buena conductividad. Esto hace que AAAC sea más adecuado para líneas de transmisión de longitud media y entornos con ciertos requisitos de resistencia mecánica., aunque el costo puede ser ligeramente mayor que el AAC.

ACSR: Conductor reforzado con acero de aluminio (ACSR) Los cables combinan la excelente conductividad del aluminio con la alta resistencia del acero.. Son especialmente adecuados para largas distancias., carga pesada, o líneas de transmisión con estrictos requisitos de resistencia mecánica. Los cables ACSR pueden resistir tormentas eficazmente, cargas de nieve, y tensión de línea, pero son relativamente más caros..

En sistemas de generación de energía solar., la elección entre CAA, AAAC, o cables ACSR depende principalmente del diseño del sistema., distancia de transmisión, requisitos de carga, y análisis costo-beneficio. Para transmisión de potencia en distancias cortas y cargas ligeras, Se puede seleccionar AAC. Para medias distancias o donde se necesita un mejor rendimiento físico, AAAC es adecuado. Para transmisión a larga distancia o condiciones ambientales complejas, ACSR suele ser la opción preferida.

¿Qué factores se deben considerar al seleccionar cables aéreos para sistemas de energía fotovoltaica??

Al seleccionar líneas aéreas para sistemas de generación de energía fotovoltaica, Se deben considerar varios factores clave para garantizar la seguridad del sistema., eficiencia, y confiabilidad a largo plazo:

Condiciones ambientales: Evaluar las condiciones climáticas del lugar de instalación., incluyendo la velocidad del viento, lluvia, rango de temperatura, carga de hielo, y corrosión por niebla salina. Elija tipos y especificaciones de cables aéreos que puedan soportar estos impactos ambientales..

Nivel de voltaje y capacidad de carga de corriente: Seleccione cables con el nivel de voltaje adecuado y suficiente capacidad de carga de corriente en función de la potencia de salida del sistema de generación de energía fotovoltaica y los requisitos de conexión a la red para garantizar una transmisión de energía segura y sin pérdidas..

Tipo de conductor: Considere usar CAA, AAAC, o conductores ACSR según la distancia de transmisión, requisitos de carga, y análisis costo-beneficio. Para transmisión de bajo voltaje, Utilice cables aislados como cables aislados de PVC o XLPE..

Planificación de ruta: Siga los principios de selección de rutas de líneas aéreas, como acortar el camino tanto como sea posible, reduciendo esquinas, evitando obstáculos potenciales y áreas peligrosas, asegurando la estabilidad de la línea, y facilidad de mantenimiento.

Resistencia mecánica y durabilidad: Elija cables que puedan soportar la tensión, presión del viento, y otras tensiones mecánicas. Para transmisión de larga distancia o entornos hostiles, ACSR de alta resistencia mecánica puede ser la mejor opción.

Instalación y mantenimiento: Considere la facilidad de instalación., costos de mantenimiento, y posibles necesidades de expansión futuras. Elija tipos de cables que sean fáciles de instalar y mantener.

Seguridad: Asegúrese de que los cables aéreos y los accesorios cumplan con las normas y regulaciones de seguridad locales., incluidos los requisitos de protección contra rayos y conexión a tierra, para prevenir incendios eléctricos y riesgos de descargas eléctricas.

Rentabilidad: Realizar una evaluación integral de los costos y beneficios de diferentes soluciones de cables eléctricos aéreos., incluyendo la inversión inicial, costos de mantenimiento operativo, y esperanza de vida, para tomar la decisión más económica y razonable.

Compatibilidad y cumplimiento: Asegúrese de que el cable aéreo seleccionado coincida con la potencia de salida del sistema fotovoltaico y cumpla con los estándares de seguridad eléctrica y los requisitos de conexión a la red nacionales o regionales..

Ampliabilidad futura: Considere la posible expansión del sistema solar.. Elija cables con cierta redundancia para facilitar actualizaciones convenientes al aumentar la capacidad de generación o mejorar el sistema en el futuro..

La selección final del cable debe basarse en la situación real del proyecto específico., incluyendo factores ambientales, restricciones presupuestarias, normas de seguridad, y requisitos de red. ZMS puede proporcionar una solución de cable integral para su proyecto de generación de energía solar, ayudando a simplificar el proceso de implementación del proyecto, acortar los períodos de construcción, y controlar eficazmente los costes.

Destacado del proyecto

ZMS unió fuerzas con Poder del Estado Verde (SGP), pionero en infraestructuras de energías renovables, equipar un monumental 10 Proyecto fotovoltaico MWP en Kabul, Afganistán.

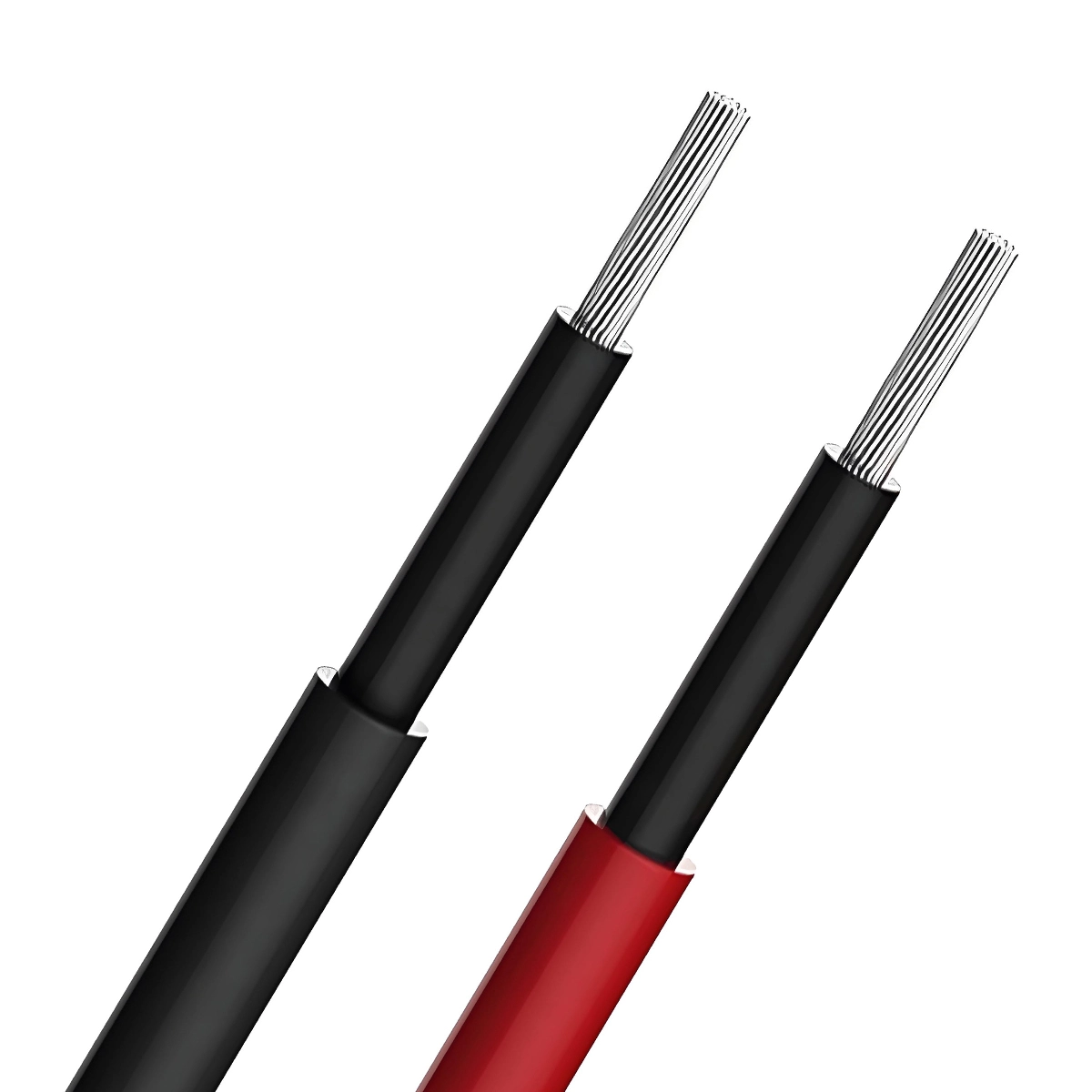

ZMS analizó exhaustivamente el proyecto fotovoltaico y le proporcionó 1Cables solares X10 y 1X6 H1Z2Z2-K, 3Cables BT X300, 3Cables MT X300, así como ACSR 185/30 cables aéreos. Complementándolos, había accesorios vitales como conectores fotovoltaicos y cajas de herramientas meticulosamente seleccionadas..

El compromiso de ZMS con la calidad y la confiabilidad facilitó una instalación sin problemas y una eficiencia operativa, Contribuir a la infraestructura energética sostenible de la región..

Servicio ZMS

Fabricación personalizada

We understand that every customer's needs are unique. Por lo tanto, Ofrecemos servicios personalizados de personalización de cables solares., Adaptando cada detalle, desde las especificaciones del cable hasta las interfaces de conexión, de acuerdo con los requisitos específicos de su proyecto., asegurando la máxima compatibilidad y eficiencia.

Logística global de respuesta rápida

Con el apoyo de nuestra red logística global, ZMS garantiza que sus pedidos de cables fotovoltaicos lleguen a cualquier rincón del mundo de forma segura y rápida. Nuestro equipo de logística profesional monitorea cada etapa del transporte para garantizar la entrega oportuna de sus productos..

Apoyo técnico

ZMS's technical support team is always on standby. Cualesquiera que sean los desafíos técnicos que encuentre, Podemos proporcionar respuestas rápidas y soluciones profesionales., garantizando una experiencia de usuario sin preocupaciones.

Producción Verde

Nuestros cables y accesorios solares cumplen estrictamente los estándares medioambientales durante el proceso de producción., minimizando su impacto en el medio ambiente. Al elegir ZMS, no sólo estás invirtiendo en cables fotovoltaicos de alta calidad sino también contribuyendo al desarrollo sostenible del planeta.