Kabel Atas

Kabel overhead dapat mengintegrasikan elektrik yang dihasilkan oleh sistem kuasa solar ke dalam grid. ZMS boleh menyediakan kabel overhed yang diperlukan seperti ACSR, DIBUKA, AAC, dan AAAC untuk pelbagai projek penjanaan kuasa fotovoltaik.

Dalam sistem kuasa solar yang disambungkan grid, Jenis kabel overhead yang digunakan bergantung pada keperluan pemasangan tertentu, seperti tahap voltan, Kapasiti pembawa semasa, kekuatan mekanikal, dan keadaan alam sekitar.

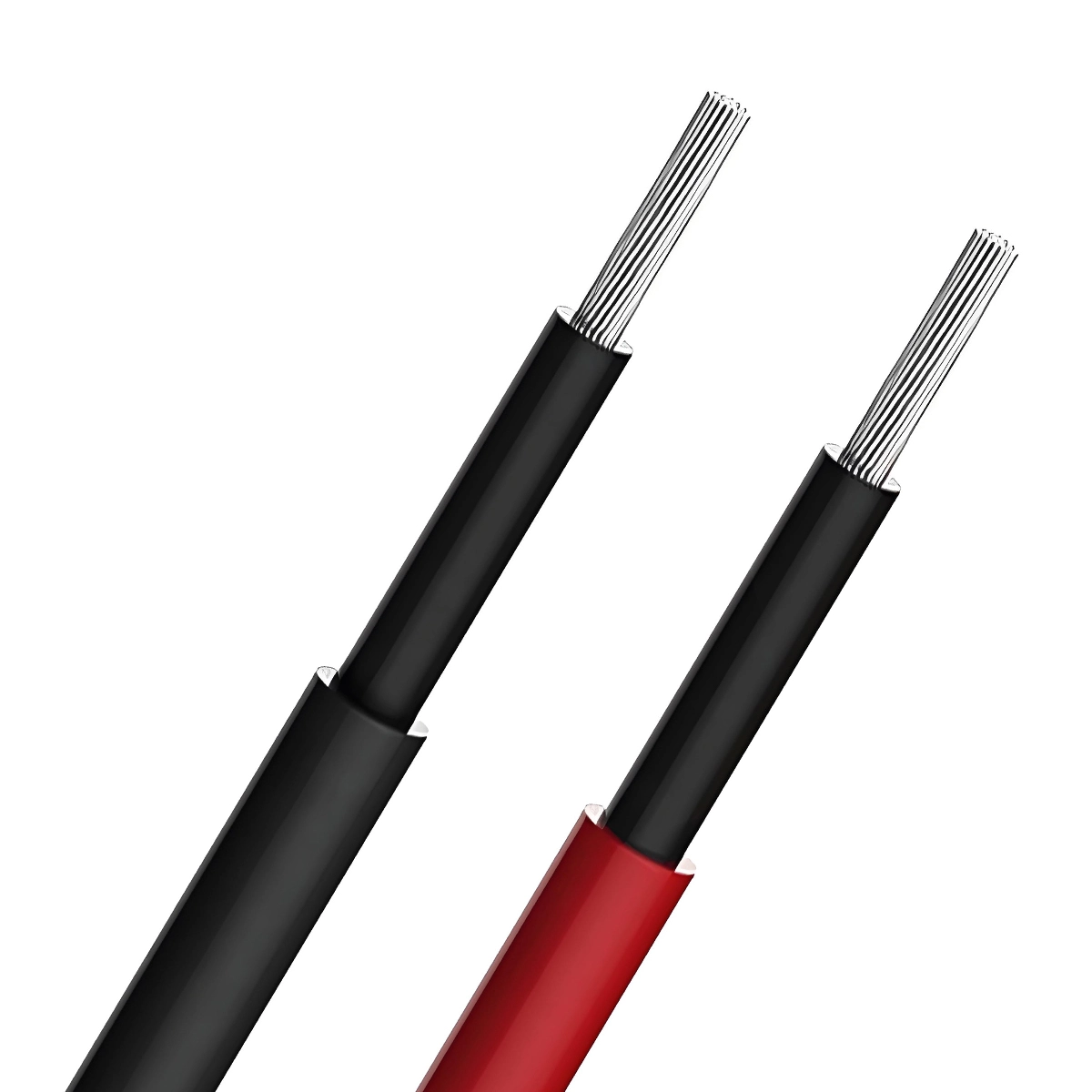

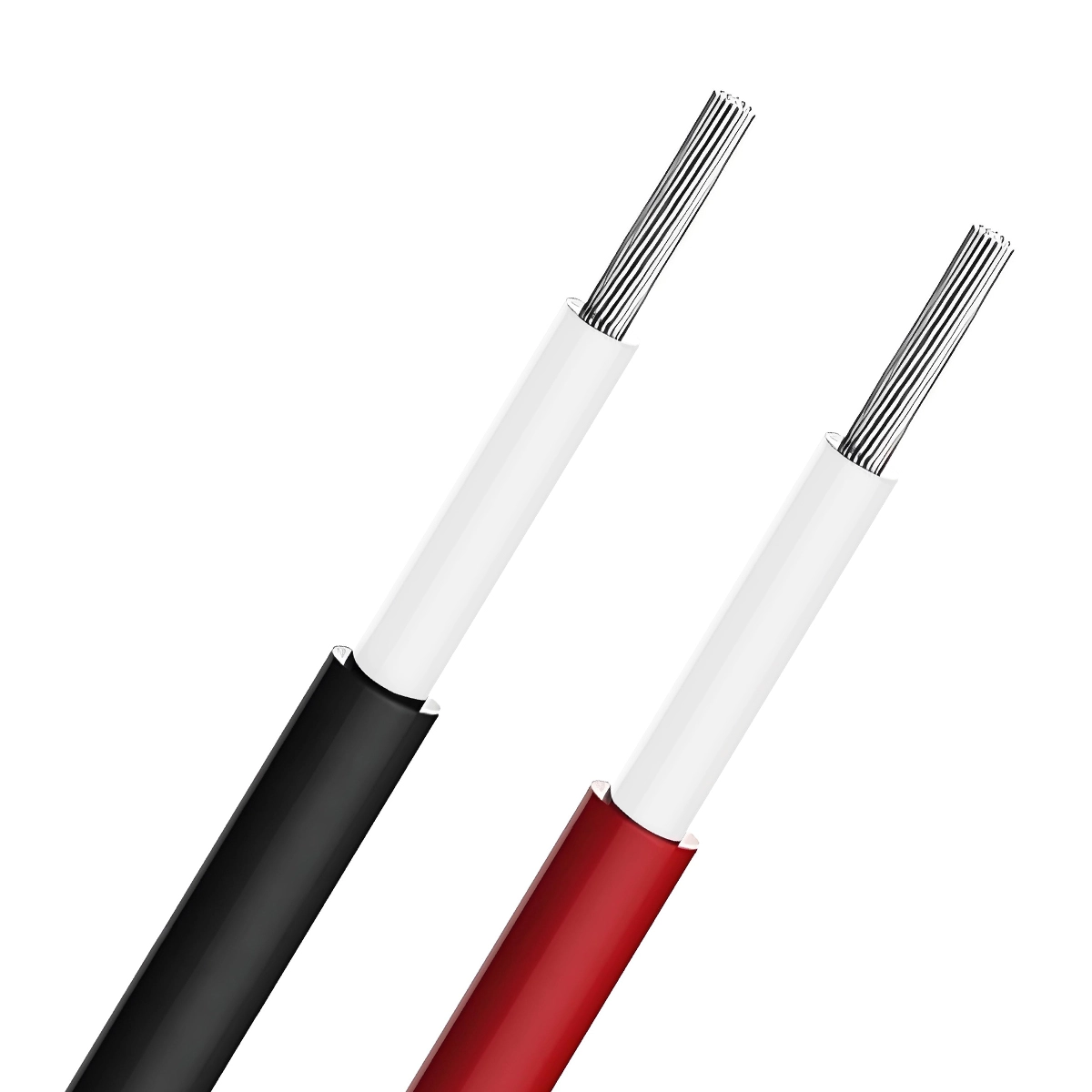

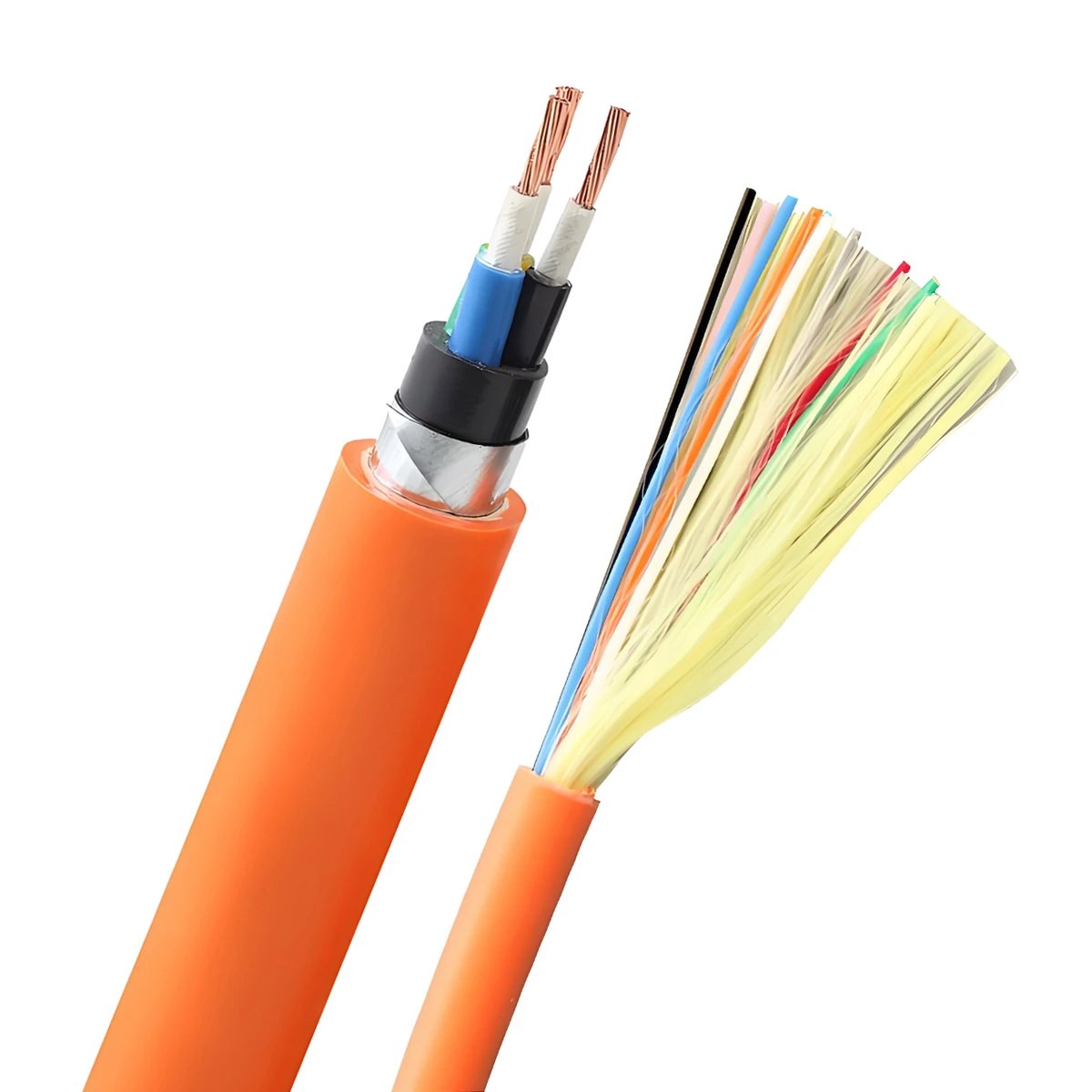

Dari kabel DC yang digunakan untuk panel solar ke kabel AC yang digunakan untuk output inverter, dan akhirnya ke kabel overhead atau bawah tanah yang menyambung ke grid, Pasukan Profesional ZMS akan secara komprehensif mempertimbangkan skala projek solar, Lokasi geografi, keadaan alam sekitar, dan keperluan sambungan grid untuk menyesuaikan penyelesaian kabel kuasa yang paling sesuai untuk anda.

AAC (Semua konduktor aluminium)

Struktur:

AAC terdiri daripada satu atau lebih helai kawat aluminium. Konduktor ini diperbuat daripada aluminium yang ditapis secara elektrik dengan kesucian minimum 99.7%. Pembinaan mengikuti standard en 60889 Taipkan Al1 mengikut BS 215.

Ciri -ciri:

Konduktor AAC sangat konduktif dan digunakan terutamanya di kawasan bandar untuk rendah, medium, dan garis overhead voltan tinggi di mana rentang pendek. Mereka mempamerkan rintangan kakisan yang sangat baik, menjadikan mereka sesuai untuk kawasan pesisir.

Piawaian:

ASTM b 230, ASTM b 231, TS IEC 1089, DIN48201, dan BS 215.

AAAC (Semua konduktor aloi aluminium)

Struktur:

Kabel AAAC terdiri daripada wayar aloi aluminium. Mereka dibuat dari aloi aluminium jenis magnesium-silikon (aloi 6201) dengan kandungan magnesium antara 0.6-0.9% dan kandungan silikon antara 0.5-0.9%. Konduktor ini direka untuk menjadi sangat konduktif dengan minimum 53% IACS.

Ciri -ciri:

Konduktor AAAC menawarkan kekuatan yang lebih baik, berat, dan sifat elektrik berbanding dengan AAC dan ACSR. Mereka mempunyai sifat tegangan menegak yang lebih baik dan rintangan kakisan yang dipertingkatkan, menjadikannya sesuai untuk talian penghantaran voltan sederhana dan tinggi. Beban pemecahan ais yang lebih rendah mereka berfaedah di kawasan dengan beban ais dan angin yang rendah. Konduktor AAAC disesuaikan berdasarkan keperluan aplikasi tertentu dan keperluan pelanggan.

Piawaian:

ASTM b 230, ASTM b 231, TS IEC 1089, DIN48201, dan BS 215.

Acsr (Keluli konduktor aluminium diperkuat)

Struktur:

Konduktor ACSR terdiri daripada beberapa konduktor keluli aluminium dan galvanized yang terkandas dalam lapisan sepusat. Inti diperbuat daripada keluli tergalvani, yang mungkin terdiri daripada 1, 7, atau 19 wayar, dan dikelilingi oleh helai aluminium. Kawat teras untuk ACSR boleh didapati dengan Kelas A, B, atau C Galvanizing.

Ciri -ciri:

Kabel ACSR serba boleh dan sesuai untuk talian penghantaran di semua tahap voltan, termasuk medan yang mencabar seperti sungai dan jurang. Dengan menyesuaikan perkadaran aluminium dan keluli, Ciri -ciri khusus untuk pelbagai aplikasi dapat dicapai. Meningkatkan kandungan keluli meningkatkan sifat antistatik, Walaupun lebih banyak kandungan aluminium meningkatkan kapasiti bawa semasa.

Piawaian:

ASTM b 230, ASTM b 231, TS IEC 1089, DIN48201, dan BS 215.

Soalan Lazim

Kabel Overhed Mana Yang Digunakan dalam Sistem Tenaga Suria?

Dalam sistem penjanaan kuasa fotovoltaik bersambung grid, sebaik sahaja kuasa DC yang dijana ditukar kepada kuasa AC oleh penyongsang dan disepadukan ke dalam grid AC, penghantaran kuasa selalunya dilakukan melalui talian atas. Lazimnya, proses sambungan grid sistem penjanaan kuasa fotovoltaik boleh berlaku dalam senario berikut:

Sambungan Terus

Untuk sistem penjanaan kuasa fotovoltaik teragih kecil, seperti fotovoltaik atas bumbung kediaman, kuasa DC boleh terus ditukar kepada kuasa AC melalui penyongsang dan kemudian disambungkan ke grid voltan rendah melalui talian pengedaran. Dalam kes ini, kabel voltan rendah bawah tanah dan kabel terlindung overhead seperti kabel ABC boleh digunakan.

Sambungan melalui Pengubah Kotak atau Integrasi Pencawang

Stesen janakuasa fotovoltaik berskala sederhana atau komersial boleh menggunakan pencawang jenis kotak (pengubah kotak) untuk menukar kuasa DC yang dijana kepada kuasa AC yang sesuai untuk penyepaduan grid melalui penyongsang, dan kemudian naikkan voltan melalui pengubah kotak untuk memadankan paras voltan grid atas, sebelum menyambung ke talian atas.

Stesen janakuasa fotovoltaik yang dipasang di tanah berskala besar biasanya memerlukan pengubah untuk meningkatkan voltan ke tahap yang lebih tinggi untuk penghantaran yang cekap. Dalam kes ini, kuasa disambungkan terus ke pencawang, yang kemudiannya mengedarkannya ke grid atas voltan tinggi atau voltan ultra tinggi.

Dalam dua senario ini, jika jarak dari stesen janakuasa ke titik sambungan grid agak pendek dan bebannya tidak besar, Kabel AAC boleh menjadi pilihan yang menjimatkan. Untuk jarak sederhana atau di mana prestasi fizikal yang lebih baik diperlukan, Kabel AAAC Mungkin pilihan yang lebih baik. Untuk penghantaran jarak jauh atau di mana keperluan kekuatan kabel khas diperlukan, terutamanya apabila talian atas perlu merentasi rupa bumi yang kompleks atau menahan keadaan cuaca yang melampau, Konduktor ACSR akan menjadi pilihan yang paling sesuai.

Apakah perbezaan antara AAC, AAAC, dan kabel ACSR?

AAC: Konduktor All-Aluminium (AAC) kabel agak rendah kos, ringan, dan mempunyai kekonduksian yang baik, menjadikan mereka sesuai untuk penghantaran jarak jauh dan keadaan beban cahaya. Namun begitu, kekuatan mereka agak rendah, dengan keupayaan tegangan terhad, yang mungkin tidak sesuai untuk jarak jauh atau situasi yang memerlukan kekuatan mekanikal yang tinggi.

AAAC: Berbanding dengan AAC, Konduktor aloi aluminium (AAAC) kabel mempunyai kekuatan mekanikal yang lebih tinggi, kekuatan tegangan yang lebih baik, dan rintangan kakisan sambil mengekalkan kekonduksian yang baik. Ini menjadikan AAAC lebih sesuai untuk talian penghantaran sederhana dan persekitaran dengan keperluan kekuatan mekanikal tertentu, Walaupun kos mungkin sedikit lebih tinggi daripada AAC.

Acsr: Konduktor bertetulang keluli aluminium (Acsr) kabel menggabungkan kekonduksian aluminium yang sangat baik dengan kekuatan keluli yang tinggi. Mereka sangat sesuai untuk jarak jauh, Beban berat, atau talian penghantaran dengan keperluan kekuatan mekanikal yang ketat. Kabel ACSR dapat dengan berkesan menahan ribut, beban salji, dan ketegangan garis tetapi agak lebih mahal.

Dalam sistem penjanaan tenaga solar, Pilihan antara AAC, AAAC, atau kabel ACSR terutamanya bergantung pada reka bentuk sistem, jarak penghantaran, keperluan beban, dan analisis kos-manfaat. Untuk penghantaran jarak jarak pendek dan beban cahaya, AAC boleh dipilih. Untuk jarak sederhana atau di mana prestasi fizikal yang lebih baik diperlukan, AAAC sesuai. Untuk penghantaran jarak jauh atau keadaan persekitaran yang kompleks, ACSR biasanya pilihan pilihan.

Faktor apa yang perlu dipertimbangkan semasa memilih kabel overhead untuk sistem kuasa PV?

Semasa memilih garis overhead untuk sistem penjanaan kuasa fotovoltaik, Beberapa faktor utama mesti dipertimbangkan untuk memastikan keselamatan sistem, kecekapan, dan kebolehpercayaan jangka panjang:

Keadaan alam sekitar: Menilai keadaan iklim tapak pemasangan, termasuk kelajuan angin, hujan, julat suhu, Beban ais, dan kakisan semburan garam. Pilih jenis dan spesifikasi kabel overhead yang dapat menahan kesan alam sekitar ini.

Tahap voltan dan kapasiti bawa semasa: Pilih kabel dengan tahap voltan yang sesuai dan kapasiti bawaan semasa yang mencukupi berdasarkan kuasa output sistem penjanaan kuasa fotovoltaik dan keperluan sambungan grid untuk memastikan penghantaran kuasa yang selamat dan lossless.

Jenis konduktor: Pertimbangkan menggunakan AAC, AAAC, atau konduktor ACSR berdasarkan jarak penghantaran, keperluan beban, dan analisis kos-manfaat. Untuk penghantaran voltan rendah, Gunakan kabel terlindung seperti kabel bertebat PVC atau XLPE.

Perancangan laluan: Ikuti Prinsip Pemilihan Laluan Talian Overhead, seperti memendekkan jalan sebanyak mungkin, Mengurangkan sudut, mengelakkan halangan yang berpotensi dan kawasan berbahaya, Memastikan kestabilan garis, dan kemudahan penyelenggaraan.

Kekuatan dan ketahanan mekanikal: Pilih kabel yang dapat menahan ketegangan, tekanan angin, dan tekanan mekanikal lain. Untuk penghantaran jarak jauh atau persekitaran yang keras, ACSR kekuatan mekanikal yang tinggi mungkin menjadi pilihan yang lebih baik.

Pemasangan dan penyelenggaraan: Pertimbangkan kemudahan pemasangan, kos penyelenggaraan, dan keperluan pengembangan masa depan yang berpotensi. Pilih jenis kabel yang mudah dipasang dan diselenggarakan.

Keselamatan: Memastikan kabel dan aksesori overhead mematuhi piawaian dan peraturan keselamatan tempatan, termasuk perlindungan kilat dan keperluan asas, untuk mengelakkan kebakaran elektrik dan risiko kejutan elektrik.

Keberkesanan kos: Menjalankan penilaian komprehensif mengenai kos dan faedah penyelesaian kabel kuasa overhead yang berbeza, termasuk pelaburan awal, kos penyelenggaraan operasi, dan jangka hayat yang dijangkakan, untuk membuat keputusan yang paling menjimatkan dan munasabah.

Keserasian dan pematuhan: Pastikan kabel overhead yang dipilih sepadan dengan kuasa output sistem photovoltaic dan memenuhi standard keselamatan elektrik nasional atau serantau.

Pengembangan masa depan: Pertimbangkan potensi pengembangan sistem solar. Pilih kabel dengan beberapa kelebihan untuk memudahkan peningkatan yang mudah apabila meningkatkan kapasiti penjanaan atau meningkatkan sistem pada masa akan datang.

Pemilihan kabel terakhir harus berdasarkan keadaan sebenar projek tertentu, termasuk faktor persekitaran, Kekangan belanjawan, piawaian keselamatan, dan keperluan grid. ZMS dapat menyediakan penyelesaian kabel yang komprehensif untuk projek penjanaan kuasa solar anda, Membantu memudahkan proses pelaksanaan projek, Memendekkan tempoh pembinaan, dan mengawal kos dengan berkesan.

Sorotan Projek

ZMS bergabung tenaga dengan Kuasa Negara Hijau (GSP), perintis dalam infrastruktur tenaga boleh diperbaharui, untuk melengkapkan monumental 10 Projek fotovoltaik MWP di Kabul, Afghanistan.

ZMS menganalisis projek PV secara komprehensif dan menyediakannya 1Kabel solar X10 dan 1X6 H1Z2Z2-K, 3Kabel X300 LV, 3Kabel X300 MV, serta ACSR 185/30 kabel atas kepala. Melengkapkan ini ialah aksesori penting seperti penyambung PV dan kotak alat yang disusun rapi.

Komitmen ZMS terhadap kualiti dan kebolehpercayaan memudahkan pemasangan dan kecekapan operasi yang lancar, menyumbang kepada infrastruktur tenaga mampan di rantau ini.

Perkhidmatan ZMS

Pembuatan Tersuai

We understand that every customer's needs are unique. Oleh itu, kami menawarkan perkhidmatan penyesuaian kabel solar yang diperibadikan, menyesuaikan setiap butiran daripada spesifikasi kabel kepada antara muka sambungan mengikut keperluan projek khusus anda, memastikan keserasian dan kecekapan maksimum.

Logistik Tindak Balas Pantas Global

Dengan sokongan rangkaian logistik global kami, ZMS memastikan pesanan kabel fotovoltaik anda sampai ke mana-mana pelosok dunia dengan selamat dan segera. Pasukan logistik profesional kami memantau setiap peringkat pengangkutan untuk memastikan penghantaran barangan anda tepat pada masanya.

Sokongan Teknikal

ZMS's technical support team is always on standby. Apa jua cabaran teknikal yang anda hadapi, kami boleh memberikan respons pantas dan penyelesaian profesional, memastikan pengalaman pengguna tanpa kebimbangan.

Pengeluaran Hijau

Kabel solar dan aksesori kami mematuhi piawaian alam sekitar semasa proses pengeluaran, meminimumkan kesannya terhadap alam sekitar. Dengan memilih ZMS, anda bukan sahaja melabur dalam kabel fotovoltaik berkualiti tinggi tetapi juga menyumbang kepada pembangunan mampan planet ini.