Mawasiliano & Kebo ya Kudhibiti

ZMS hufanya aina kamili ya Mawasiliano & kudhibiti kebo kwa mfumo wa jua. Nyaya hizi za hali ya juu zinahakikisha uhamishaji wa data isiyo na mshono na usimamizi bora wa mfumo, na usambazaji sahihi wa nguvu na udhibiti wa utendaji.

Kamba za mawasiliano katika mfumo wa nguvu ya jua huwezesha uhamishaji wa data kati ya vifaa kama paneli za jua, waingiaji, na mifumo ya ufuatiliaji, kuwezesha ufuatiliaji wa utendaji wa wakati halisi, Udhibiti wa mbali, na utambuzi. ZMS inaweza kutoa nyaya za macho au nyuzi za nyuzi za multimode na vituo vinavyohitajika na nyaya zilizopotoka za jozi.

Kudhibiti nyaya zinasimamia usambazaji wa nguvu na udhibiti wa utendaji ndani ya mfumo wa nguvu ya jua kwa kupitisha ishara za kudhibiti kwa vifaa kama inverters, wafuatiliaji, na relays. Wanahakikisha utekelezaji sahihi wa amri za kiutendaji, mifumo ya usalama, na maingiliano ya sehemu nyingi za mfumo. Udhibiti wa ZMS na nyaya za vifaa vinaweza kudumisha ufanisi na kuegemea kwa mifumo ya PV kwa kuratibu udhibiti wa nguvu na kutoa kazi za kinga.

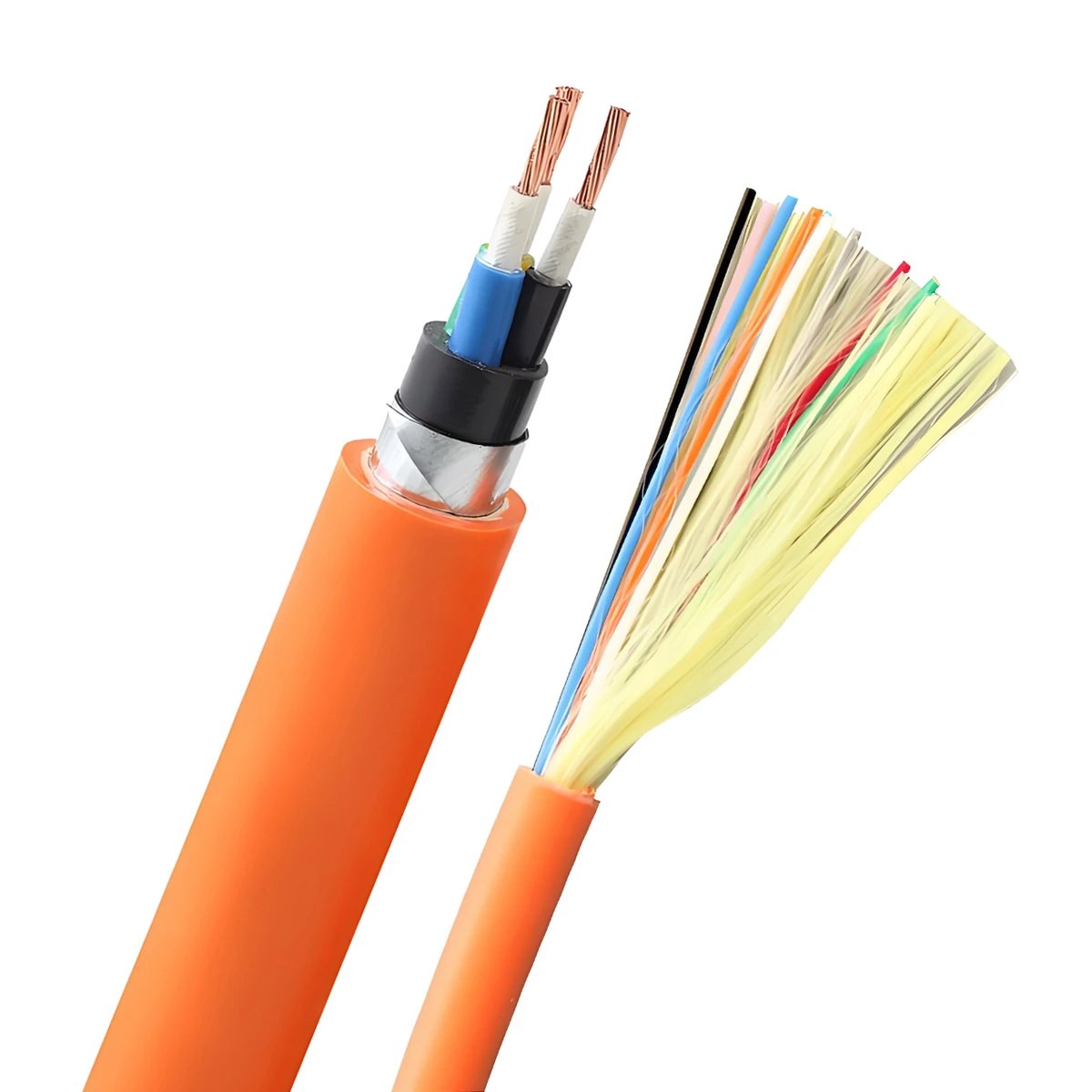

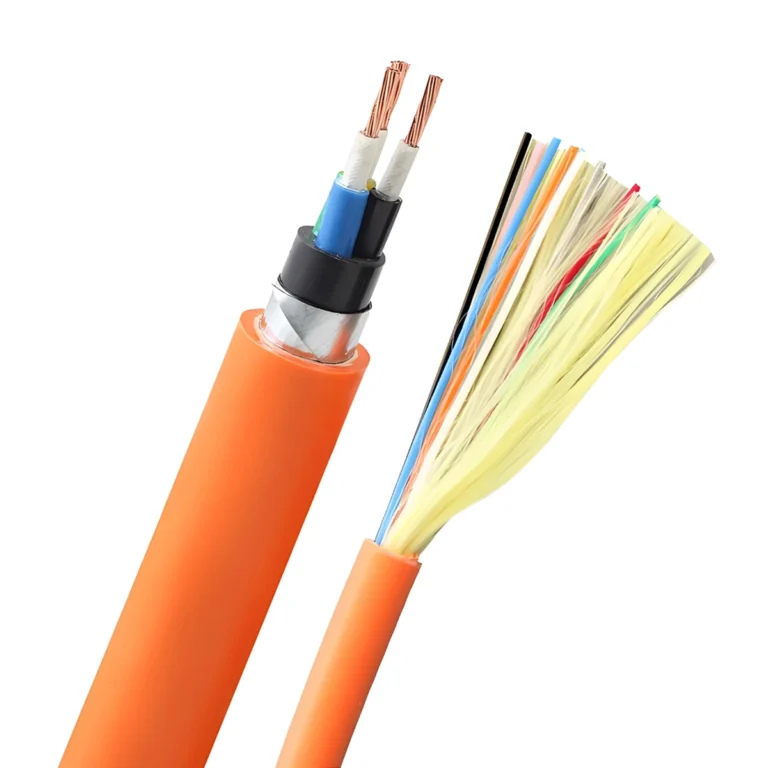

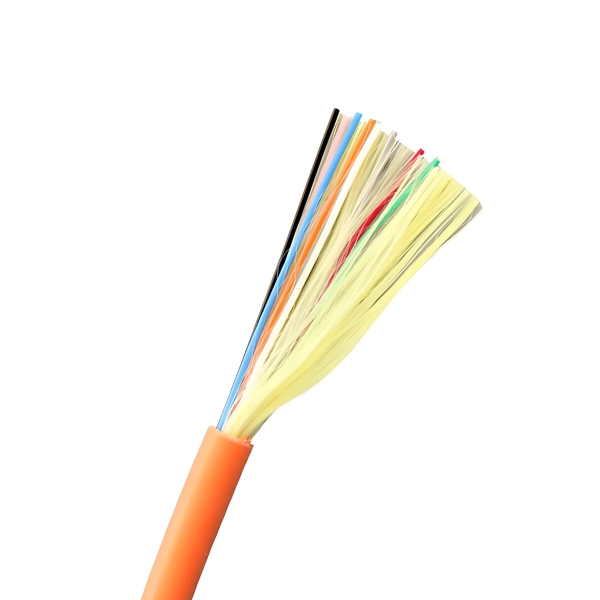

Cable ya mawasiliano ya ZMS

Njia moja ya nyuzi ya macho

Njia moja za nyuzi za nyuzi za ZMS zimeundwa kwa usambazaji wa data ya umbali mrefu na upotezaji mdogo wa ishara, Kuwafanya kuwa bora kwa kuunganisha vitanzi vya SMU na vituo vya inverter na kuunganisha vituo vya inverter na vyumba vya SCADA. Nyaya hizi hutoa bandwidth ya juu na uvumbuzi wa chini, Kuhakikisha mawasiliano ya kuaminika na ya kasi kubwa kwa ufuatiliaji na udhibiti wa wakati halisi katika mifumo ya nishati ya jua.

Multimode Fiber Optic Cable

ZMS hutoa nyaya za macho za nyuzi za multimode iliyoundwa kwa usambazaji wa data ya umbali mfupi ndani ya mifumo ya nishati ya jua. Nyaya hizi ni kamili kwa kuunganisha vifaa anuwai ndani ya kituo cha inverter, Kutoa utendaji thabiti na viwango vya juu vya usambazaji wa data. Ubunifu wa multimode huruhusu ishara nyingi kutumwa wakati huo huo, Kuongeza ufanisi na kuegemea kwa mfumo wako wa nguvu ya jua.

Cable ya nyuzi ya nyuzi

Mabamba yetu ya macho ya nyuzi ya kivita yamejengwa ili kuhimili hali kali za mazingira, Kutoa ulinzi ulioongezwa dhidi ya uharibifu wa mwili na kuhakikisha usambazaji wa data usioingiliwa. Nyaya hizi zinafaa kwa mitambo ya nje ambapo uimara wa ziada unahitajika na mitambo iliyozikwa.

Cable ya jozi iliyopotoka

Kamba za jozi zilizopotoka za ZMS hutoa suluhisho la gharama kubwa kwa mawasiliano kati ya vifaa vya mfumo wa jua. Wakati nyaya za jozi zilizopotoka zina bandwidth ndogo na umbali na zinahusika kwa kuingilia kati. Nyaya zetu zina muundo maalum wa ngao ili kupunguza uingiliaji wa umeme. Na kukomesha hiari, Ni anuwai na rahisi kufunga.

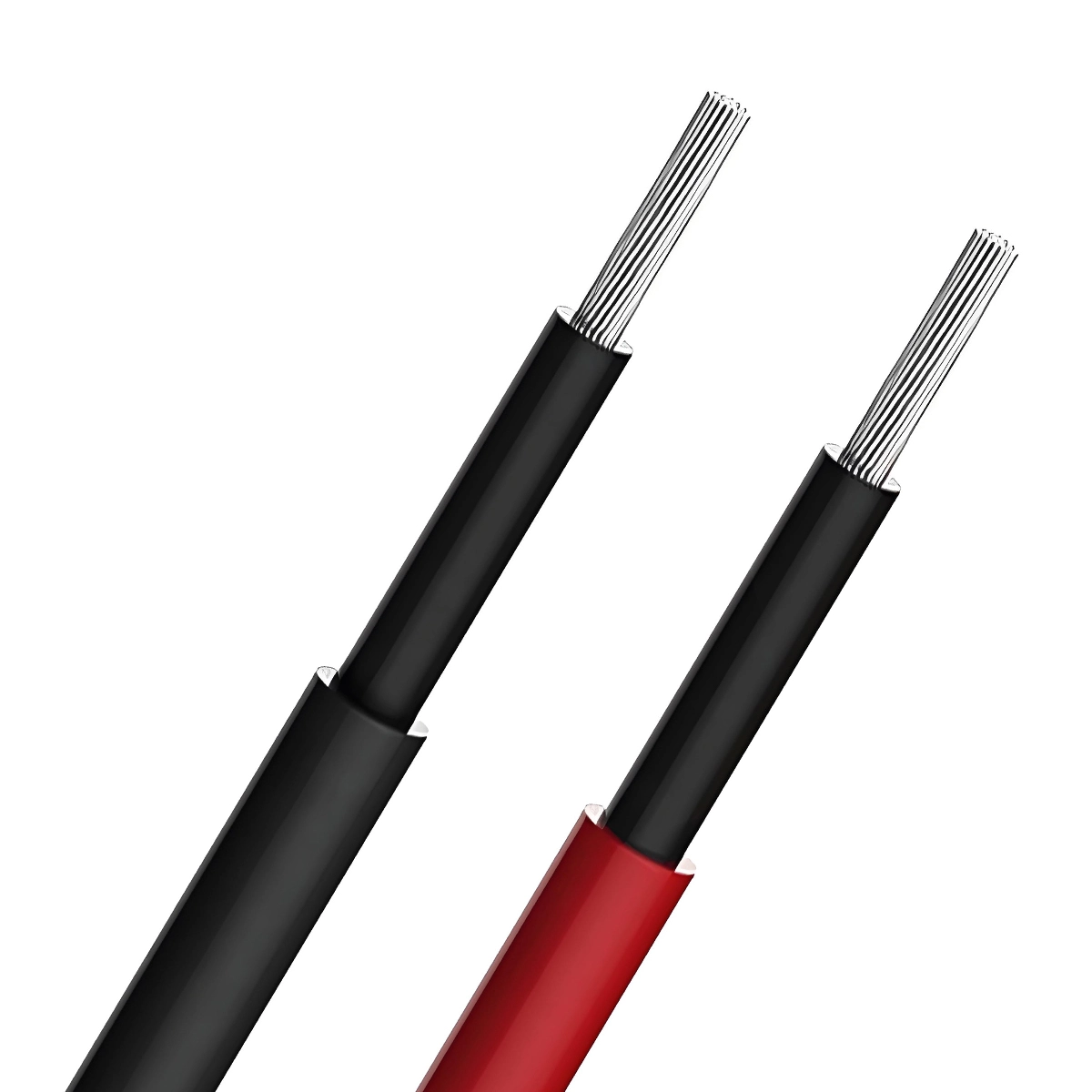

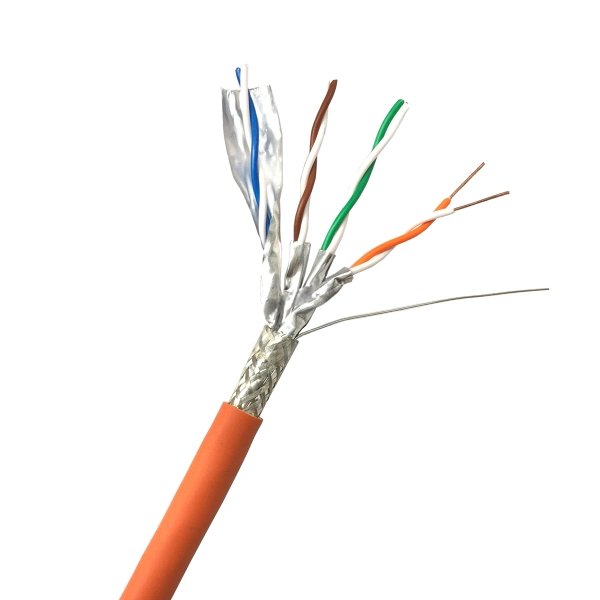

ZMS kudhibiti kebo

Cable ya Udhibiti wa Multi Multi

Nyaya za kudhibiti ubora zinazotolewa na ZMS zinahakikisha usambazaji sahihi wa nguvu na udhibiti wa utendaji ndani ya mifumo ya nishati ya jua. Imejengwa na conductors za shaba, Shielding, na insulation ya XLPE, Nyaya hizi hutoa utendaji bora wa umeme na uimara.

- Kondakta: Shaba

Idadi ya cores: Inaweza kugawanywa kulingana na mahitaji maalum ya maombi; Hesabu za kawaida za msingi ni pamoja na 2, 3, 4, 5, 7, 10, 12, 14, 16, 19, na 24 - Nyenzo za insulation: PVC/XLPE

- Shielding: Mkanda wa Copper-Plastic Composite/Aluminium-Plastic Composite/Copper Wire Braid

- Nyenzo za sheathing:: PVC

- Kuinama radius: 20D (msingi mmoja), 15D (Multi-msingi)

- Viwango: IEC 60502, IEC 60332-3

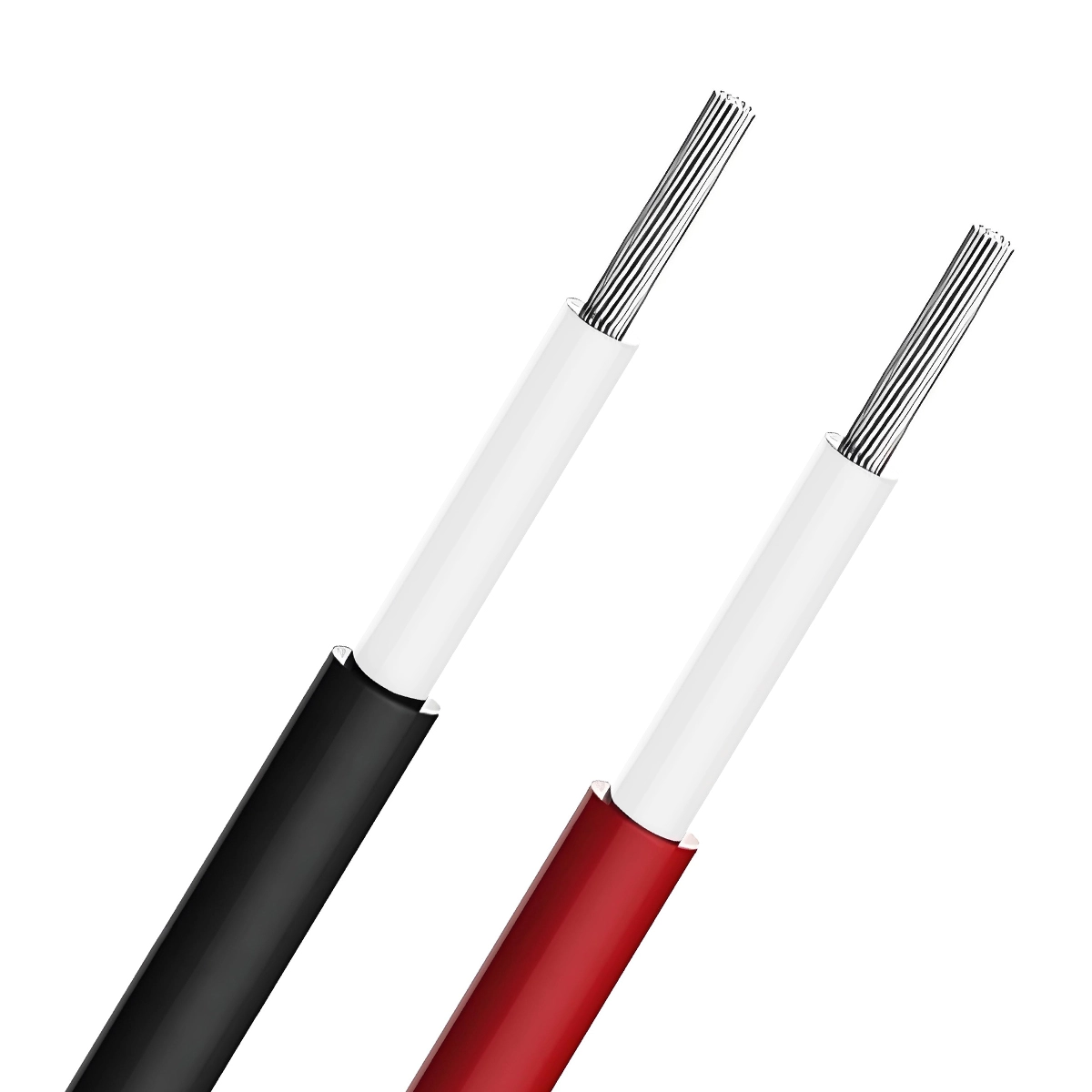

Kebo ya ala

Mabamba ya vifaa vilivyotengenezwa na ZMS huonyesha kinga ya hali ya juu na insulation ya PVC kutoa mifumo ya jua na kinga bora dhidi ya kuingiliwa kwa umeme, Kuhakikisha usambazaji sahihi wa data na wazi.

- Kondakta: Shaba/shaba iliyokatwa

- Insulation: PE/PVC/XLPE

- Shielding: Mkanda wa mchanganyiko wa alumini-plastiki

- Nyenzo za sheathing: PVC / Lszh

- Joto la kufanya kazi: 0˚C hadi +50˚C

- Viwango: BS 5308, BS en 60228, IEC 60332-1

Maswali Yanayoulizwa Mara kwa Mara

Je! Kamba za mawasiliano zinaathiri usahihi wa kuhesabu mfumo wa umeme wa jua?

Katika mfumo wa uzalishaji wa umeme wa jua, Jukumu la msingi la nyaya za mawasiliano ni kusambaza ishara za kudhibiti na data ya kuangalia, kama pato la nguvu, Hali ya Mfumo, kengele mbaya, na habari nyingine. Nyaya hizi hazishiriki moja kwa moja katika maambukizi ya nishati ya umeme. Kwa hiyo, nyaya za mawasiliano zenyewe haziathiri moja kwa moja usahihi wa kuhesabu katika mfumo wa umeme wa jua.

Hata hivyo, Ikiwa nyaya za mawasiliano hupata makosa (kama vile upatanishi wa ishara, kuingiliwa, au kukatwa), Inaweza kusababisha mfumo wa ufuatiliaji kutoweza kupokea kwa usahihi au kusambaza data, na hivyo kuathiri usahihi na wakati wa ufuatiliaji wa mfumo. Kwa mfano, Ucheleweshaji wa maambukizi ya data au makosa yanaweza kuzuia wafanyikazi wa matengenezo kutoka mara moja kuelewa hali halisi ya mfumo wa uzalishaji wa umeme au kusababisha kurekodi data sahihi, na hivyo kuathiri takwimu na uchambuzi wa uzalishaji wa nguvu.

Kwa hiyo, Wakati nyaya za mawasiliano haziathiri uzalishaji halisi wa nishati ya umeme, Ni muhimu kwa usimamizi mzuri na matengenezo ya mfumo. Hii inahusiana moja kwa moja na tathmini ya utendaji wa jumla na utoshelezaji wa ufanisi wa mfumo wa umeme wa jua. Kuhakikisha ubora na matengenezo sahihi ya nyaya za mawasiliano ni muhimu kwa kudumisha ufuatiliaji wa kuaminika na utendaji mzuri wa mfumo wa umeme wa jua.

Je! Ni aina gani za nyaya zinahitajika kwa mifumo ya nguvu ya jua?

Kama sehemu muhimu ya suluhisho endelevu za nishati, Utendaji salama na mzuri wa mifumo ya uzalishaji wa umeme wa jua hutegemea usanidi unaofaa na utumiaji wa nyaya mbali mbali maalum. Aina za nyaya zinazohitajika katika mfumo wa umeme wa jua ni pamoja na yafuatayo:

Solar DC Cable

Cables hizi zimeundwa mahsusi kwa kuunganisha moduli za Photovoltaic (Paneli za jua) na kwa maambukizi ya nguvu kati ya moduli kwenye sanduku la Mchanganyiko wa DC. Kwa kuzingatia mfiduo wao wa moja kwa moja kwa mazingira ya nje, Lazima wawe na sifa zifuatazo:

- Upinzani wa UV: Ili kuzuia uharibifu wa utendaji kwa sababu ya mfiduo wa jua wa muda mrefu.

- Upinzani wa hali ya hewa: Kuhimili hali tofauti za hali ya hewa, pamoja na joto kali, unyevu, na mchanga uliopigwa na upepo.

- Upinzani wa kunyunyizia chumvi: Inafaa kwa maeneo ya pwani kuzuia uharibifu wa chumvi.

- Kurudisha moto: Ili kupunguza hatari za moto na kuongeza usalama wa mfumo.

- Nguvu ya mitambo: Kuvumilia usanikishaji na shinikizo za mazingira bila kuharibiwa kwa urahisi.

AC Cable

Kamba za AC hutumiwa kwenye mwisho wa pato la inverter kusambaza nguvu iliyobadilishwa ya AC kwa bodi ya usambazaji ya AC au moja kwa moja kwenye gridi ya taifa. Nyaya hizi zinahitaji kufikia viwango vya unganisho la gridi ya taifa na zina mali nzuri za insulation na upinzani wa joto ili kuhakikisha usambazaji salama na mzuri wa nguvu.

Cable ya mawasiliano ya data

Katika mfumo wa uzalishaji wa umeme wa jua, Kamba za mawasiliano ya data hufanya kama daraja la habari. Sio tu kusambaza data ya umeme inayotokana na safu ya Photovoltaic lakini pia inapeleka habari ya hali ya kweli ya inverters na vifaa vingine vya ufuatiliaji kwa mfumo mkuu wa ufuatiliaji kupitia mitandao ya waya au ya waya isiyo na waya (pamoja na macho ya nyuzi) Kwa utaftaji wa mfumo na utambuzi wa makosa.

Kebo ya Kudhibiti

Kamba za kudhibiti hutumiwa kuunganisha watawala, waingiaji, na vifaa vingine vya kusaidia ndani ya mfumo, Kuhakikisha udhibiti wa kiotomatiki na ufuatiliaji mzuri. Nyaya hizi zinahitaji kuwa na utulivu mzuri wa maambukizi ya ishara na uwezo wa kuingilia kati ili kuhakikisha utekelezaji sahihi wa amri za udhibiti.

Cable ya kutuliza

Nyaya za kutuliza zina jukumu muhimu katika ulinzi wa usalama wa mfumo mzima wa umeme wa jua. Wanatoa njia ya kupinga chini ya kutekeleza mikondo ya umeme haraka au mikondo ya makosa ya mfumo, kuzuia mshtuko wa umeme na uharibifu wa vifaa, na hivyo kuhakikisha usalama wa wafanyikazi na vifaa.

Kebo ya Juu

Katika hali fulani za ufungaji, kama vile maambukizi ya umbali mrefu au vizuizi vya eneo, nyaya za juu hutumiwa kwa unganisho la gridi ya taifa ya mfumo wa umeme wa jua. Nyaya hizi zinahitaji kubuniwa mahsusi kupinga uharibifu wa mwili wa nje na sababu za hali ya hewa wakati wa kudumisha ubora mzuri na nguvu ya mitambo.

Wakati wa kuchagua nyaya hizi za jua, Ni muhimu sio tu kuzingatia tabia zao na mazingira yanayotumika lakini pia kuhakikisha kuwa nyaya zote na vifaa vinazingatia viwango vya usalama wa umeme na kanuni za tasnia ili kuhakikisha operesheni ya muda mrefu na kufuata mfumo wa uzalishaji wa umeme wa jua.

Je! Ni asilimia ngapi ya gharama ya ujenzi ambayo nyaya zinawakilisha katika kituo cha nguvu cha Photovoltaic?

Gharama ya nyaya kwenye Photovoltaic (Pv) Kituo cha nguvu kawaida huwakilisha karibu 10% ya jumla ya gharama ya ujenzi. Asilimia hii inaweza kutofautiana kulingana na mambo kadhaa kama vile kiwango cha mradi, Uteuzi wa vifaa, Tofauti za kikanda, na kushuka kwa soko. Kulingana na makadirio kadhaa:

- Moduli za Photovoltaic (Paneli za jua) akaunti kwa takriban 50% ya jumla ya gharama ya vifaa.

- Inverters na vifaa vingine vya vifaa vya umeme kwa karibu 10%.

- Nyaya na miundo ya kuweka kila akaunti kwa karibu 10%.

Kwa hiyo, Gharama za cable kwa ujumla hufanya juu 10% ya jumla ya gharama ya ujenzi. Hata hivyo, Hii ni makisio mabaya, na sehemu halisi inaweza kutofautiana kulingana na bajeti maalum na bei ya vifaa vya mradi. Zaidi ya hayo, na maendeleo katika teknolojia na mabadiliko ya soko, Asilimia hii inaweza kuwa chini ya marekebisho.

ZMS inaweza kutoa suluhisho kamili na zilizobinafsishwa za cable na huduma za nukuu zilizojumuishwa kwa miradi yako ya nguvu ya jua. Jisikie huru kuwasiliana nasi!

Muhtasari wa Mradi

ZMS iliungana na Nguvu ya Jimbo la Kijani (GSP), mwanzilishi katika miundombinu ya nishati mbadala, kuandaa monumental 10 Mradi wa photovoltaic wa MWP huko Kabul, Afghanistan.

ZMS ilichambua kwa kina mradi wa PV na kuutoa 1X10 na 1X6 nyaya za jua H1Z2Z2-K, 3Kebo za X300 za LV, 3Kebo za X300 za MV, pamoja na ACSR 185/30 nyaya za juu. Kukamilisha hivi vilikuwa vifaa muhimu kama viunganishi vya PV na visanduku vya zana vilivyoratibiwa kwa uangalifu.

Kujitolea kwa ZMS kwa ubora na kutegemewa kuliwezesha usakinishaji laini na ufanisi wa kufanya kazi, kuchangia miundombinu ya nishati endelevu ya kanda.

Huduma ya ZMS

Utengenezaji Uliobinafsishwa

We understand that every customer's needs are unique. Kwa hiyo, tunatoa huduma za kubinafsisha kebo za jua, kurekebisha kila undani kutoka kwa vipimo vya kebo hadi miingiliano ya unganisho kulingana na mahitaji yako mahususi ya mradi, kuhakikisha utangamano wa juu na ufanisi.

Uratibu wa Majibu ya Haraka Ulimwenguni

Kwa msaada wa mtandao wetu wa kimataifa wa vifaa, ZMS huhakikisha kwamba maagizo yako ya kebo ya photovoltaic yanafika sehemu yoyote ya dunia kwa usalama na upesi. Timu yetu ya kitaalamu ya vifaa hufuatilia kila hatua ya usafirishaji ili kuhakikisha utoaji wa bidhaa zako kwa wakati unaofaa.

Msaada wa Kiufundi

ZMS's technical support team is always on standby. Changamoto zozote za kiufundi unazokutana nazo, tunaweza kutoa majibu ya haraka na ufumbuzi wa kitaalamu, kuhakikisha matumizi ya mtumiaji bila wasiwasi.

Uzalishaji wa Kijani

Kebo zetu za jua na vifaa vinafuata kwa ukali viwango vya mazingira wakati wa mchakato wa uzalishaji, kupunguza athari zao kwa mazingira. Kwa kuchagua ZMS, sio tu unawekeza katika nyaya za ubora wa juu wa photovoltaic lakini pia unachangia maendeleo endelevu ya sayari..