Kebo ya H1Z2Z2-K

H1Z2Z2-K Cable Inatumika hasa kwa uhusiano kati ya paneli za jua na kati ya paneli za jua na vizuizi/masanduku ya makutano katika mifumo ya uzalishaji wa nguvu ya PV.

ZMS Solar H1Z2Z2-K Cable hutumia vifaa vya chini vya moshi-halogen visivyo na maji yaliyounganishwa na polyolefin, ambayo inaweza kuzoea hali mbaya ya hali ya hewa. Inaangazia upinzani na unyevu na joto, joto la juu na la chini, asidi na alkali, Upinzani wa Ozone, Upinzani wa UV, Kurudisha moto, Upinzani wa Abrasion, na ugumu wa nguvu.

Cable ya jua H1Z2Z2-K katika safu ya cable ya ZMS ina ufanisi mkubwa wa maambukizi na maisha marefu ya huduma hadi hadi 25 miaka. Aina hii ya kebo ya PV ni rahisi kusanikisha, salama, na ya kuaminika, na inaweza kutumika sana katika miradi anuwai ya uhandisi wa nishati ya jua, Uzalishaji wa umeme wa jua, Mimea ya nguvu ya Photovoltaic, na kadhalika.

- Vipimo: 1.5~ 240mm²

- Kiwango cha bidhaa: EN50618:2014

- Uthibitisho wa bidhaa: Tüv, Ce, ISO

H1Z2Z2-K Vigezo vya kiufundi vya H1Z2Z2-K

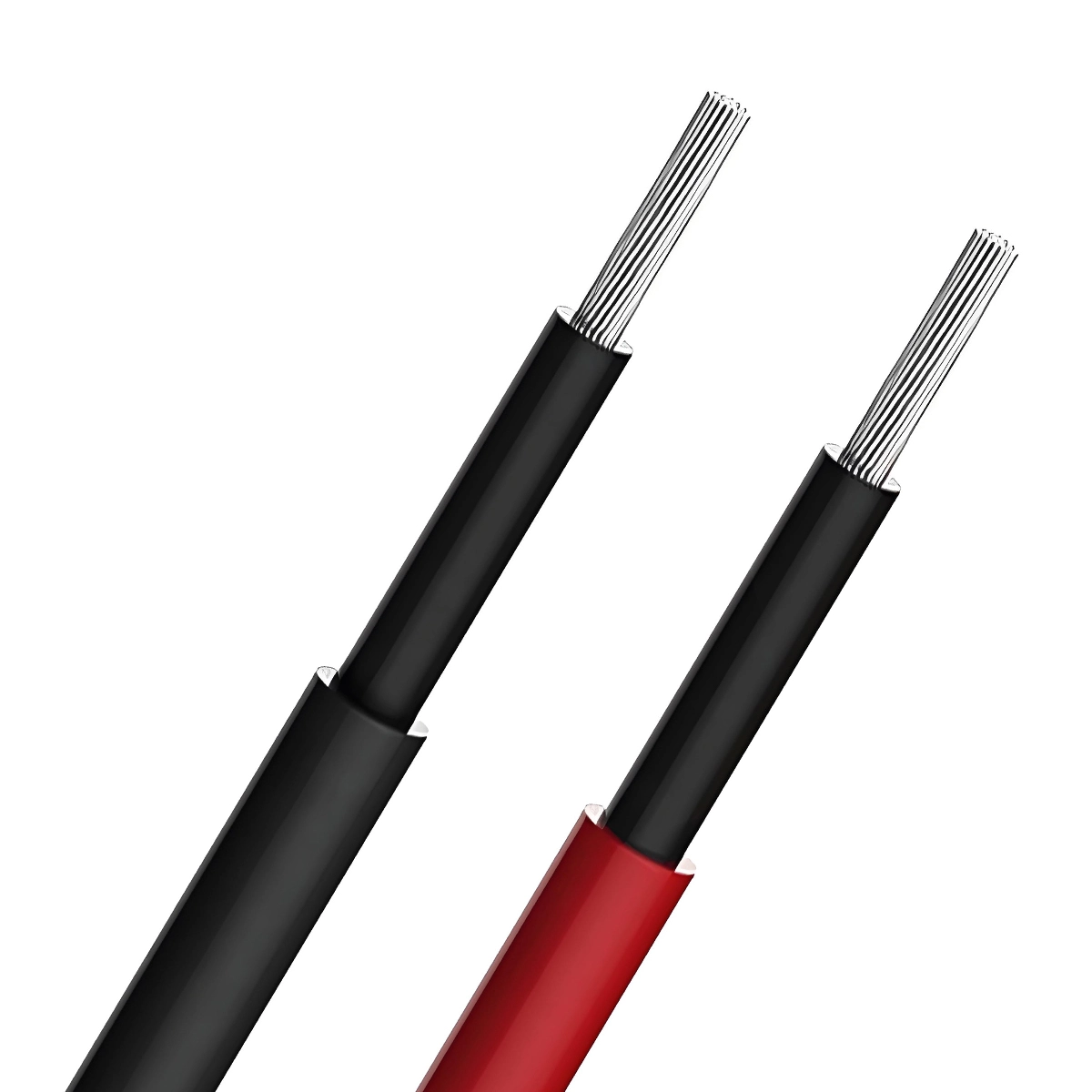

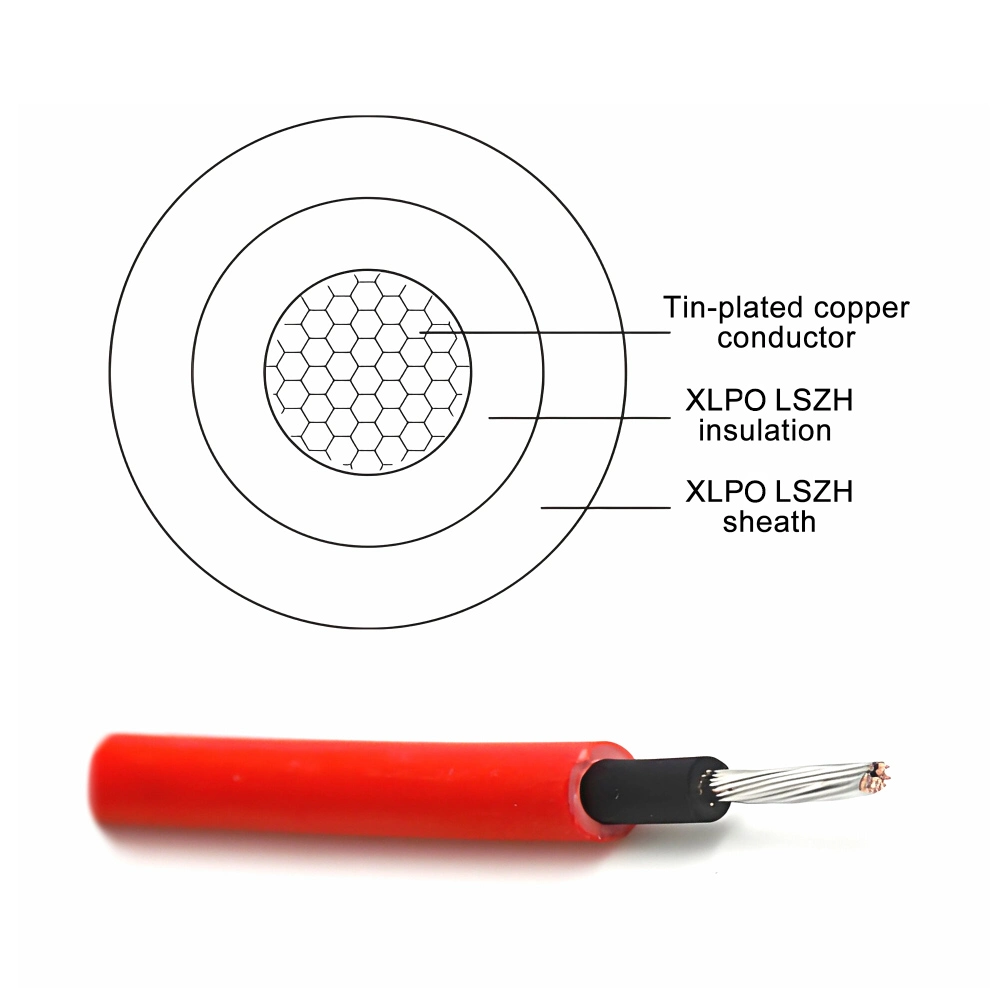

- Kondakta: 99.9% Shaba iliyowekwa kwenye bati

- Insulation: Moshi wa chini wa halogen-bure-iliyounganishwa na polyolefin iliyounganishwa (Nyeusi)

- Ala: Moshi wa chini wa halogen-bure-iliyounganishwa na polyolefin iliyounganishwa (Nyeusi/Nyekundu)

- Voltage iliyokadiriwa ya AC (Uo/u): 1.0/1.0kV

- DC iliyokadiriwa voltage (UO): 1.5kV (Kati ya conductors, kondakta duniani)

- Upeo wa mfumo wa voltage (Moja): 1.2kV

- Joto la kufanya kazi la conductor: -45° C hadi +120 ° C.

- Joto la kawaida: -40° C hadi +90 ° C.

- Cable kuwekewa joto: Sio chini kuliko -25 ° C.

- Ukadiriaji wa moto wa moto: EN50625 / UL1571

- Kima cha chini cha Kipenyo cha Kupinda: 6D (D: Kipenyo cha nje cha cable)

- Njia za ufungaji: Kuwekewa mfereji, Trench ya kina kirefu, Cable Trench kuwekewa, Kuweka handaki, Sandwich kuwekewa, Kuweka mkono wa angani, kuwekewa angani, na kadhalika.

- Maisha ya Huduma: Miaka ≥25

Udhibitishaji wa ZMS H1Z2Z2-K

Vigezo vya muundo wa cable ya H1Z2Z2-K

| Uainishaji (mm²) | Kipenyo cha conductor (mm) | Unene wa insulation ya nominella (mm) | Unene wa kawaida wa sheath (mm) | Takriban kipenyo cha nje cha kipenyo (mm) | Takriban uzito wa cable (Kilo/km) | Upeo wa DC upinzani wa conductor saa 20 ° C. (Ω/km) |

| 1× 1.5 | 1.58 | 0.7 | 0.8 | 4.6 | 35 | 13.7 |

| 1× 2.5 | 2.02 | 0.7 | 0.8 | 5.0 | 47 | 8.21 |

| 1× 4 | 2.58 | 0.7 | 0.8 | 5.6 | 65 | 5.09 |

| 1× 6 | 3.17 | 0.7 | 0.8 | 6.2 | 87 | 3.39 |

| 1× 10 | 4.1 | 0.7 | 0.8 | 7.6 | 132 | 1.95 |

| 1× 16 | 5.6 | 0.7 | 0.9 | 8.8 | 197 | 1.24 |

| 1× 25 | 7.1 | 0.9 | 1.0 | 10.9 | 303 | 0.795 |

| 1× 35 | 8.5 | 0.9 | 1.1 | 12.5 | 410 | 0.565 |

| 1× 50 | 10.2 | 1.0 | 1.2 | 14.6 | 573 | 0.393 |

| 1× 70 | 12.0 | 1.1 | 1.2 | 16.6 | 777 | 0.277 |

| 1× 95 | 14.0 | 1.1 | 1.3 | 18.8 | 1030 | 0.210 |

| 1× 120 | 16.0 | 1.2 | 1.3 | 21.0 | 1284 | 0.164 |

| 1× 150 | 17.0 | 1.4 | 1.4 | 22.6 | 1594 | 0.132 |

| 1× 185 | 19.0 | 1.6 | 1.6 | 25.4 | 1979 | 0.108 |

| 1× 240 | 22.0 | 1.7 | 1.7 | 28.8 | 2540 | 0.0817 |

H1Z2Z2-K ya muda mrefu inayoruhusiwa ya sasa ya kubeba

| Ufungaji | Cable moja hewani | Cable moja Kwenye uso wa kitu | Nyaya mbili katika mawasiliano Kwenye uso wa kitu |

| Sehemu ya msalaba (mm²) | Kubeba uwezo (A) | ||

| 1.5 | 30 | 29 | 24 |

| 2.5 | 41 | 39 | 33 |

| 4 | 55 | 52 | 44 |

| 6 | 70 | 67 | 57 |

| 10 | 98 | 93 | 79 |

| 16 | 132 | 125 | 107 |

| 25 | 176 | 167 | 142 |

| 35 | 218 | 207 | 176 |

| 50 | 276 | 262 | 221 |

| 70 | 347 | 330 | 278 |

| 95 | 416 | 395 | 333 |

| 120 | 488 | 464 | 390 |

| 150 | 566 | 538 | 453 |

| 185 | 644 | 612 | 515 |

| 240 | 775 | 736 | 620 |

| Joto la kufanya kazi | 120° C. | ||

| Joto la kawaida | 60° C. | ||

Maswali Yanayoulizwa Mara kwa Mara

Kwa nini utumie nyaya maalum kwa mifumo ya Photovoltaic?

Kamba za Photovoltaic zimeundwa mahsusi kwa miradi ya uzalishaji wa nguvu ya Photovoltaic, na sifa za insulation na sheathing ambazo nyaya za kawaida hazimiliki.

Ikiwa nyaya za kawaida hutumiwa katika mfumo wa PV, Wao ni kukabiliwa na kutofaulu katika mazingira magumu ya nje, kupunguza sana maisha ya mfumo mzima wa nguvu ya jua. Zaidi ya hayo, Inaweza kusababisha upakiaji wa sasa, kushuka kwa nguvu ya voltage, makosa ya kizazi cha mara kwa mara, na ufanisi wa kizazi cha chini katika mimea ya nguvu ya Photovoltaic, Hata uwezekano wa kusababisha moto kwenye mmea.

Kwa hiyo, kuhakikisha operesheni thabiti ya muda mrefu ya mimea ya nguvu ya Photovoltaic kwa 25 miaka, Ni muhimu kuchagua nyaya iliyoundwa mahsusi kwa mifumo ya photovoltaic, kama vile H1Z2Z2-K au PV1-F.

Je! Ni maelezo gani yanayopaswa kuchaguliwa kwa nyaya za H1Z2Z2-K PV?

Katika mifumo ya kawaida ya Photovoltaic, Chaguzi za kawaida ni H1Z2Z2-K 1×4 na H1Z2Z2-K 1×6 nyaya. Kwa ujumla, Sehemu kubwa za msalaba zinaonyesha uwezo mkubwa wa kubeba mzigo.

Mawazo kama vile voltage ya kufanya kazi, Uwezo wa sasa, na kiwango cha joto cha mazingira pia kinapaswa kuwekwa ndani. Baada ya kuamua voltage na mahitaji ya sasa, Rejea jedwali la parameta ya nyaya za H1Z2Z2-K ili uchague vipimo sahihi.

Ikiwa unakutana na kutokuwa na uhakika katika kuchagua maelezo ya cable, Timu yetu ya Ufundi ya ZMS inapatikana ili kutoa suluhisho zilizoundwa.

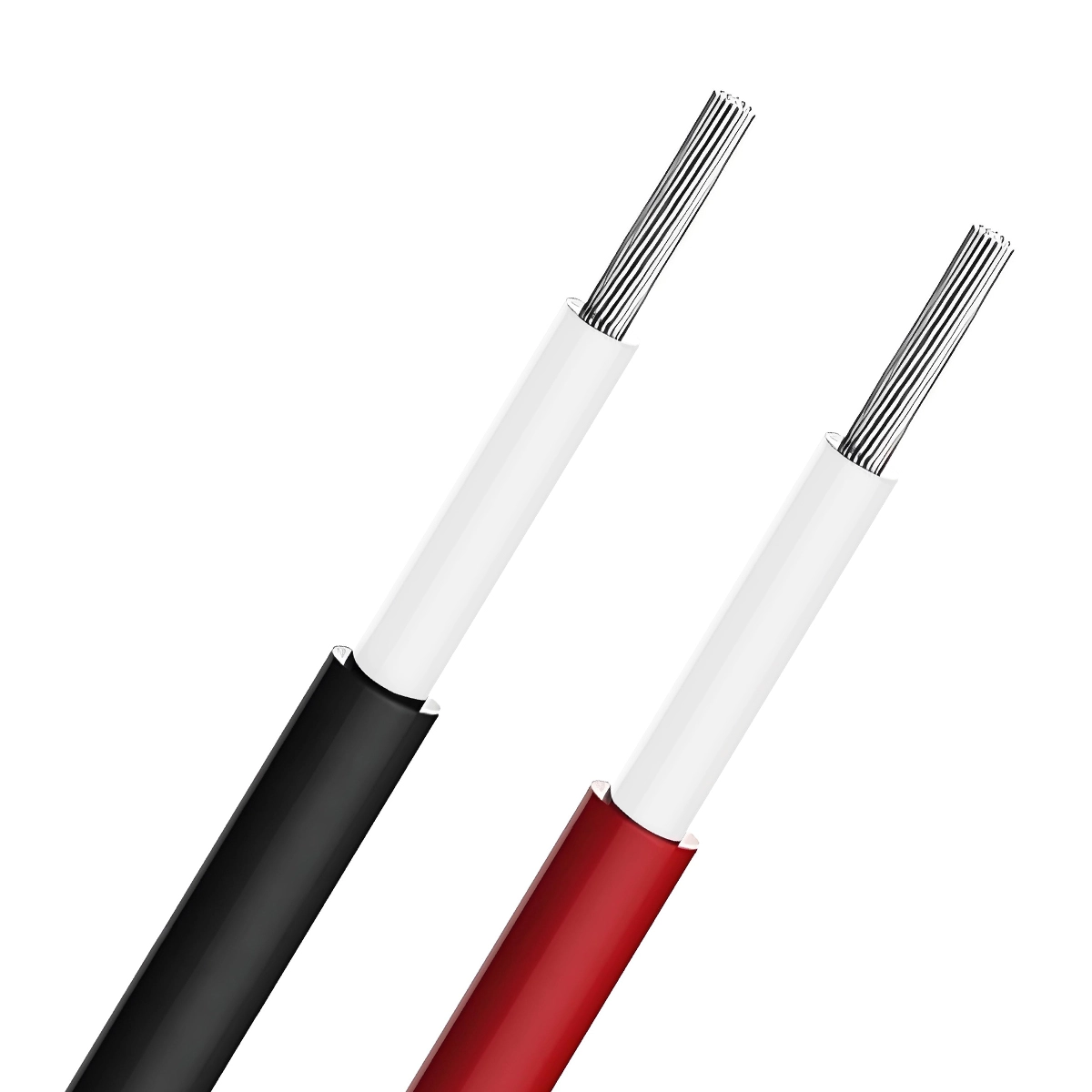

Je! Ni tofauti gani kati ya nyaya za H1Z2Z2-K na PV1-F Photovoltaic?

Cable ya PV1-F ni toleo la zamani la jua la jua ambalo linaambatana na kiwango cha Tüv 2PFG1169, na udhibitisho wake wa kawaida umekoma kusasisha. Kwa kulinganisha, Cable ya H1Z2Z2-K Photovoltaic inakubaliana na Tüv EN50618 ya hivi karibuni:2014 udhibitisho.

Viwango vya voltage vinatofautiana kati ya nyaya za PV1-F na H1Z2Z2-K. PV1-F ina rating ya voltage ya DC: 1.0KV na AC: Uo/u: 0.6/1.0kV, wakati H1Z2Z2-K ina rating ya voltage ya DC: 1.5KV na AC: Uo/u: 1.0/1.0kV. H1Z2Z2-K inaweza kutoa ufanisi wa juu wa maambukizi na utulivu.

Kwa upande wa muundo, Cable ya PV1-F ina safu moja ya insulation, wakati cable ya H1Z2Z2-K inachukua muundo wa insulation wa safu mbili. Hii hufanya cable ya H1Z2Z2-K kuwa bora katika uimara na ulinzi, Hasa dhidi ya uharibifu wa mitambo na sababu za mazingira.

Kwa muhtasari, Cable ya jua ya H1Z2Z2-K ni ya juu zaidi katika muundo, Inatoa utendaji wa juu wa umeme na mitambo, Inafaa kwa mazingira yanayohitaji zaidi ya maombi. Kwa upande mwingine, Cable ya jua ya PV1-F ni faida katika ufanisi wa gharama, Inafaa kwa mifumo ya kawaida ya Photovoltaic.

Kwa maanani ya ufanisi, Cable ya PV1-F inaweza kutumika kwa viunganisho vya mfululizo kati ya moduli za Photovoltaic na miunganisho inayofanana kutoka kwa kamba hadi sanduku za usambazaji za DC. Wakati huo huo, Cable ya H1Z2Z2-K inaweza kutumika kwa unganisho kati ya sanduku za usambazaji na inverters, na pia kwa miunganisho ya moja kwa moja ya sasa katika inverters kubwa.

Je! Ni tofauti gani kati ya matumizi ya DC na AC ya nyaya za H1Z2Z2-K Photovoltaic?

Cables za H1Z2Z2-K zinaweza kutumika kwa mizunguko yote miwili ya DC (1.5kV) na mizunguko ya AC (1.0/1.0kV). Katika mifumo ya uzalishaji wa nguvu ya Photovoltaic, Tofauti zao maalum za maombi ni kama ifuatavyo:

Kwa matumizi ya DC:

- Uunganisho wa mfululizo kati ya moduli za Photovoltaic

- Uunganisho sambamba kati ya kamba

- Uunganisho sambamba kutoka kwa kamba hadi sanduku za usambazaji za DC

- Uunganisho kutoka kwa sanduku za usambazaji za DC hadi inverters

Kwa matumizi ya AC:

- Uunganisho kutoka kwa inverters kwenda kwa wabadilishaji wa hatua

- Uunganisho kutoka kwa wabadilishaji wa hatua hadi vifaa vya usambazaji

- Unganisho kutoka kwa vifaa vya usambazaji hadi gridi ya taifa au watumiaji

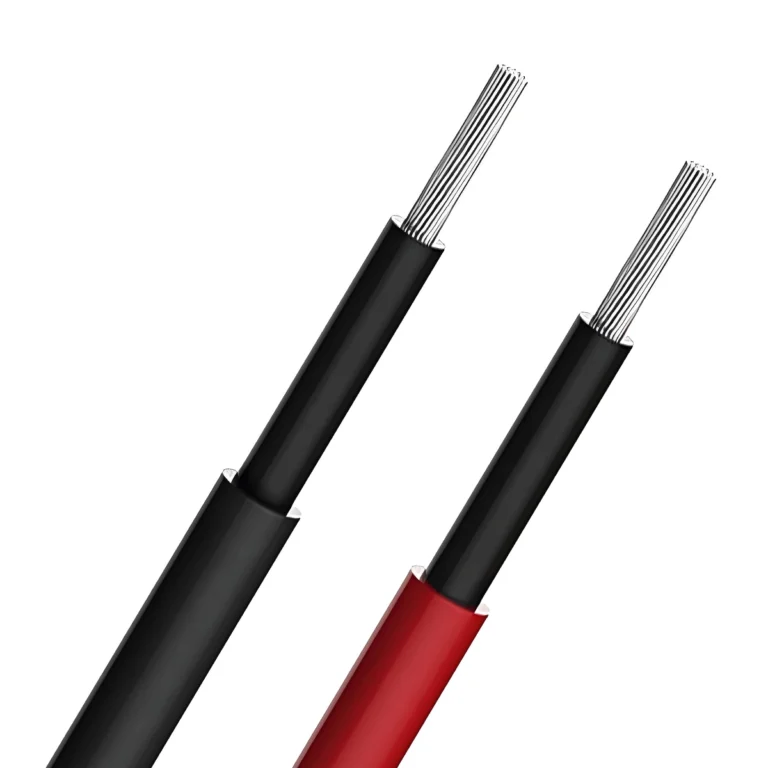

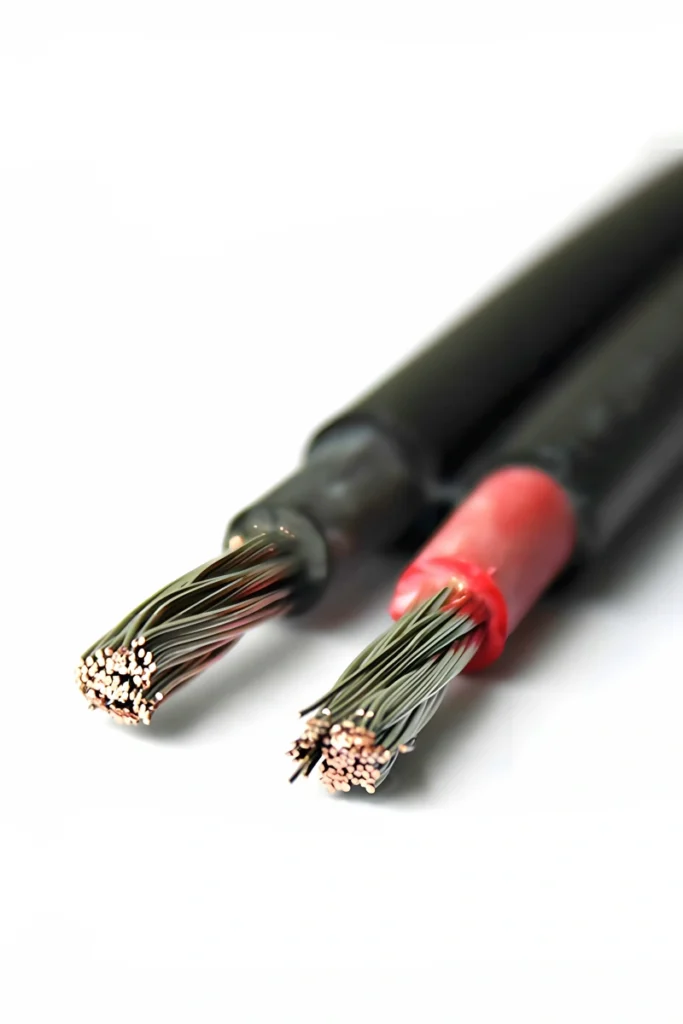

Kwa nini nyaya za jua hugawanyika kuwa nyekundu na nyeusi?

Katika tasnia ya Photovoltaic, Kutumia nyaya nyekundu na nyeusi imekuwa njia inayokubaliwa sana ya kitambulisho. Kusudi lao la msingi ni kutofautisha kati ya miti mizuri na hasi. Katika mizunguko ya DC, kawaida, Waya nyekundu za jua zinaonyesha pole chanya ya sasa, wakati waya nyeusi za jua zinaonyesha pole hasi. Utofautishaji wa rangi hii husaidia kutambua haraka polarity ya miunganisho ya Photovoltaic wakati wa ufungaji na matengenezo ya mifumo ya jua, hivyo kuzuia makosa ya wiring.

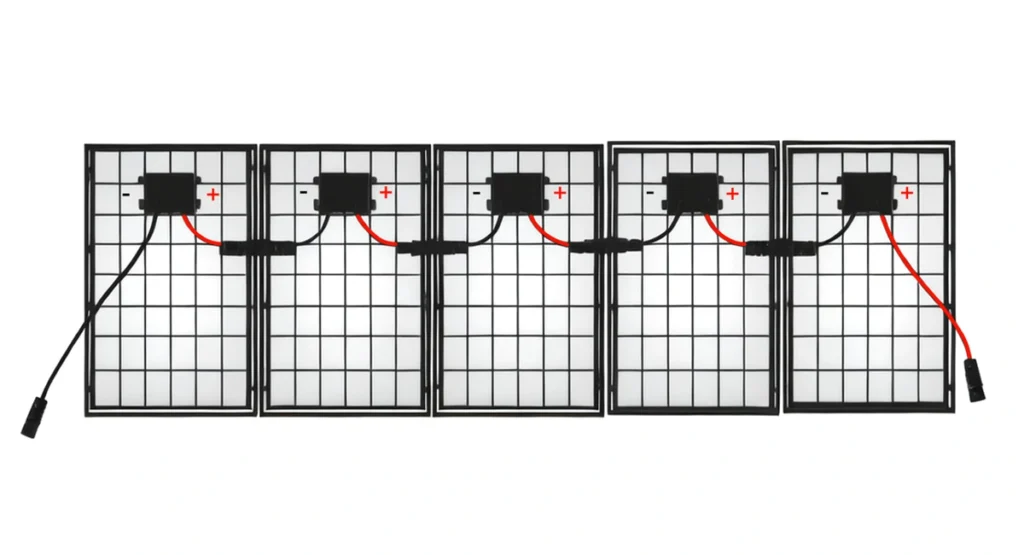

Jinsi ya kutengeneza viunganisho vya jopo la jua na unganisha paneli za jua na nyaya za H1Z2Z2-K?

Mara tu viunganisho vya jua vimeandaliwa, Paneli za jua zinaweza kushikamana sambamba, Mfululizo, au usanidi wa mseto.

Katika unganisho sambamba, Vituo vyema na hasi vya paneli nyingi za Photovoltaic zimeunganishwa tofauti. Njia hii ya kuogelea huongeza pato la jumla la mfumo, Inafaa kwa hali zinazohitaji pato la sasa la sasa.

Katika unganisho la mfululizo, Vituo vyema na hasi vya paneli nyingi za Photovoltaic zimeunganishwa. Njia hii ya kuogelea huongeza pato la jumla la mfumo, Inafaa kwa hali zinazohitaji pato la juu la voltage.

Uunganisho wa mseto unachanganya njia za wiring zinazofanana na mfululizo. Inajumuisha kuunganisha paneli zingine za Photovoltaic sambamba na kisha kuunganisha mchanganyiko huu sambamba katika safu. Njia za wiring za mseto huruhusu mchanganyiko rahisi kukidhi mahitaji ya nishati ya hali tofauti.

ZMS inaweza kutoa viunganisho anuwai vya Universal MC kando, ambazo zinaendana kikamilifu na viunganisho vya MC4. Zaidi ya hayo, Tunaweza pia kutoa nyaya za upanuzi wa jopo la jua na viunganisho vilivyotengenezwa kabla ili kukidhi mahitaji yako tofauti.

Muhtasari wa Mradi

ZMS iliungana na Nguvu ya Jimbo la Kijani (GSP), mwanzilishi katika miundombinu ya nishati mbadala, kuandaa monumental 10 Mradi wa photovoltaic wa MWP huko Kabul, Afghanistan.

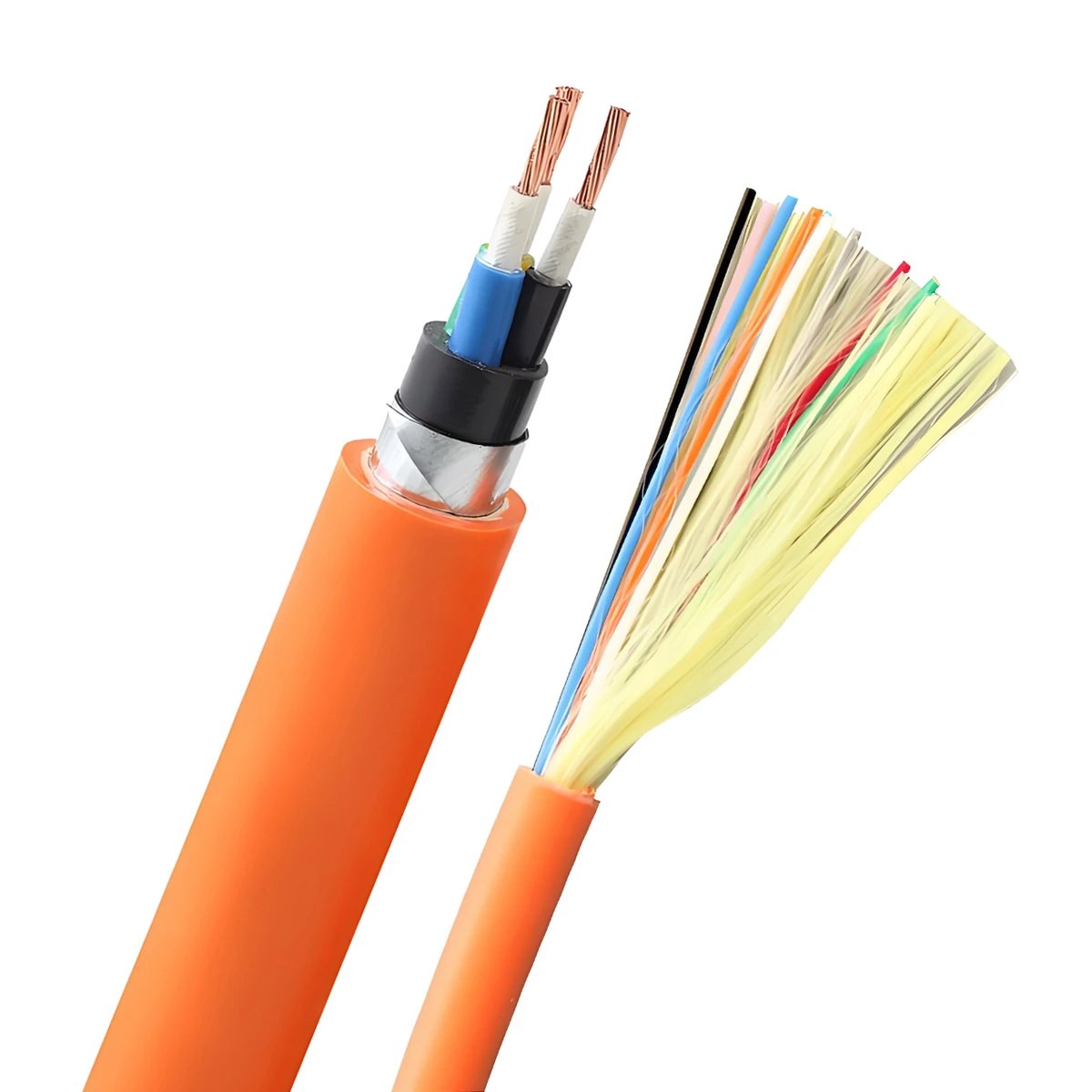

ZMS ilichambua kwa kina mradi wa PV na kuutoa 1X10 na 1X6 nyaya za jua H1Z2Z2-K, 3Kebo za X300 za LV, 3Kebo za X300 za MV, pamoja na ACSR 185/30 nyaya za juu. Kukamilisha hivi vilikuwa vifaa muhimu kama viunganishi vya PV na visanduku vya zana vilivyoratibiwa kwa uangalifu.

Kujitolea kwa ZMS kwa ubora na kutegemewa kuliwezesha usakinishaji laini na ufanisi wa kufanya kazi, kuchangia miundombinu ya nishati endelevu ya kanda.

Huduma ya ZMS

Utengenezaji Uliobinafsishwa

We understand that every customer's needs are unique. Kwa hiyo, tunatoa huduma za kubinafsisha kebo za jua, kurekebisha kila undani kutoka kwa vipimo vya kebo hadi miingiliano ya unganisho kulingana na mahitaji yako mahususi ya mradi, kuhakikisha utangamano wa juu na ufanisi.

Uratibu wa Majibu ya Haraka Ulimwenguni

Kwa msaada wa mtandao wetu wa kimataifa wa vifaa, ZMS huhakikisha kwamba maagizo yako ya kebo ya photovoltaic yanafika sehemu yoyote ya dunia kwa usalama na upesi. Timu yetu ya kitaalamu ya vifaa hufuatilia kila hatua ya usafirishaji ili kuhakikisha utoaji wa bidhaa zako kwa wakati unaofaa.

Msaada wa Kiufundi

ZMS's technical support team is always on standby. Changamoto zozote za kiufundi unazokutana nazo, tunaweza kutoa majibu ya haraka na ufumbuzi wa kitaalamu, kuhakikisha matumizi ya mtumiaji bila wasiwasi.

Uzalishaji wa Kijani

Kebo zetu za jua na vifaa vinafuata kwa ukali viwango vya mazingira wakati wa mchakato wa uzalishaji, kupunguza athari zao kwa mazingira. Kwa kuchagua ZMS, sio tu unawekeza katika nyaya za ubora wa juu wa photovoltaic lakini pia unachangia maendeleo endelevu ya sayari..