AC Cable ya jua

ZMS hutoa chini-voltage na kati-voltage Cable ya jua ya jua Kwa aina anuwai ya miradi ya Photovoltaic, pamoja na cable ya H07V-U, Cable ya H07RN-F, NYY CABLE, Cable ya N2xsy, Na2xs(F)2na cable, na kadhalika.

Katika mifumo ya Photovoltaic, Kamba za jua za jua hutumiwa hasa kwa unganisho la gridi ya taifa ya uzalishaji wa umeme wa jua. Wakati kituo cha nguvu cha Photovoltaic kiko karibu na kituo cha mzigo au yenyewe ni kizazi kilichosambazwa, Pato la sasa kutoka kwa inverter linaweza kuunganishwa moja kwa moja kwenye gridi ya chini ya voltage kupitia nyaya za AC. Ili kuungana na gridi ya kati au ya juu-voltage, Nyaya za AC zinahitaji kutumiwa kuungana na transformer kwanza, ambayo itaongeza voltage kwa kiwango kinachofaa kabla ya kuunganishwa na badala.

ZMS inaweza kubuni na kutoa suluhisho zinazofaa za cable kulingana na mahitaji tofauti ya miradi ya Photovoltaic. Cables zetu za jua za jua zinaweza kuongeza ufanisi wa maambukizi ya nguvu, Punguza upotezaji wa nishati, na hakikisha kuwa kila nishati ya jua hutumika kikamilifu.

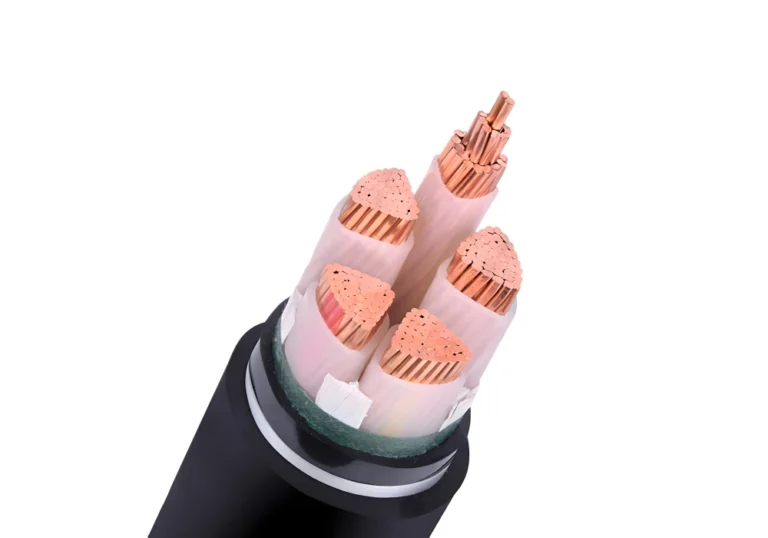

1.8/3kv cu(Al)/Xlpe/(Swa)/Cable ya PVC

- Kondakta: Shaba/alumini

- Insulation: Xlpe

- Silaha: Swa (Waya za chuma zilizowekwa)

- Nyenzo za sheathing: PVC/LSZH/MDPE

- Voltage ya kawaida: 1.8/3Kv

- Idadi ya cores: 1-5

- Kuinama radius: 15 x d (msingi mmoja), 10 x d (Multi-msingi)

- Kawaida: IEC60502-1

- Maombi: Cable ya usambazaji kutoka kwa inverter ya kamba hadi paneli ya kamba ya LT. Cables za MDPE zinaweza kuzikwa, Kamba za PVC na nyaya za LSZH zinafaa kwa matumizi ya ndani na nje.

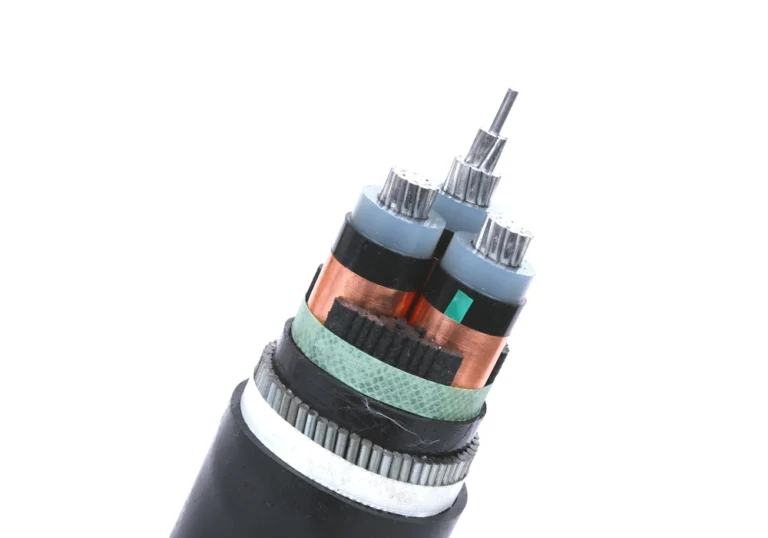

12.7/22KV kati-voltage cable

- Kondakta: Shaba/alumini

- Insulation: Xlpe

- Silaha: SWA/AWA

- Nyenzo za sheathing: PVC/LSZH

- Voltage ya kawaida: 12.7/22kV

- Idadi ya cores: 1/3

- Kawaida: IEC60502, BS 6622

- Maombi: Cable tatu za kati za kati zinafaa kwa nyaya za usambazaji kutoka kwa kibadilishaji cha ushuru wa inverter hadi MCR. Cables za msingi wa kati-voltage zinaweza kutumika kwa jopo kuu la MV kwa nguvu ya transfomer LV upande.

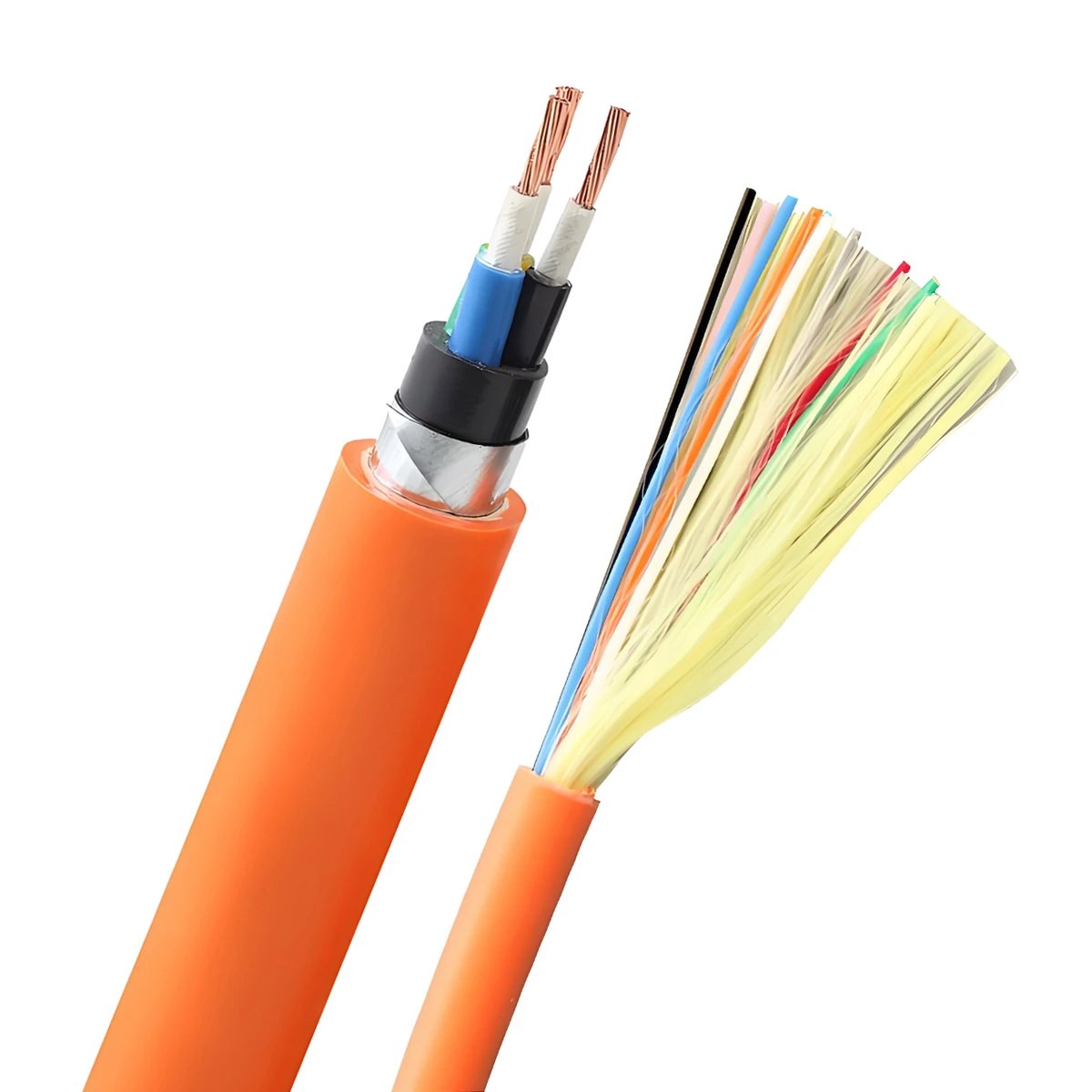

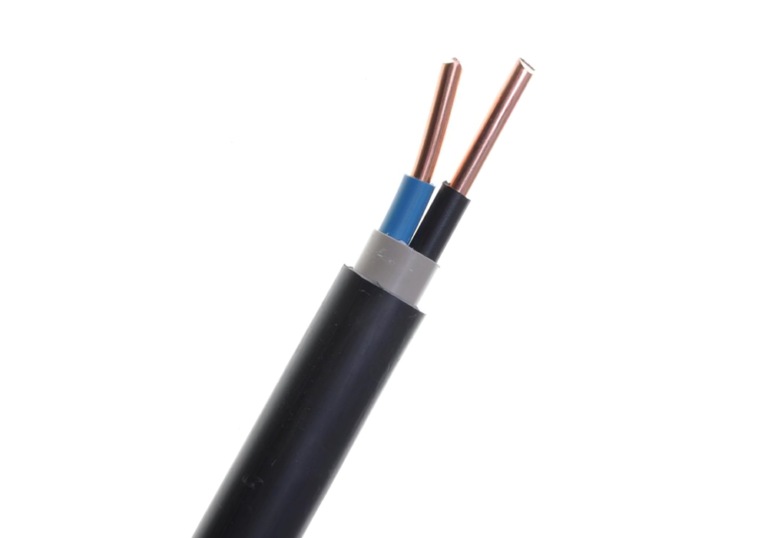

NYY CABLE

- Kondakta: Shaba

- Insulation: PVC

- Nyenzo za sheathing: PVC

- Voltage ya kawaida (Uo/u): 0.6/1.0kV

- Upeo unaoruhusiwa wa voltage ya kufanya kazi katika mifumo ya awamu 3: 1.2 kV

- Joto la kawaida: -5° C. – +70° C.

- Ukadiriaji wa moto wa moto: VDE 0482-332-1-2/IEC 60332-1

- UV sugu: Ndio

- Maombi: Kwa usanikishaji uliowekwa katika hewa ya bure, katika ardhi na maji

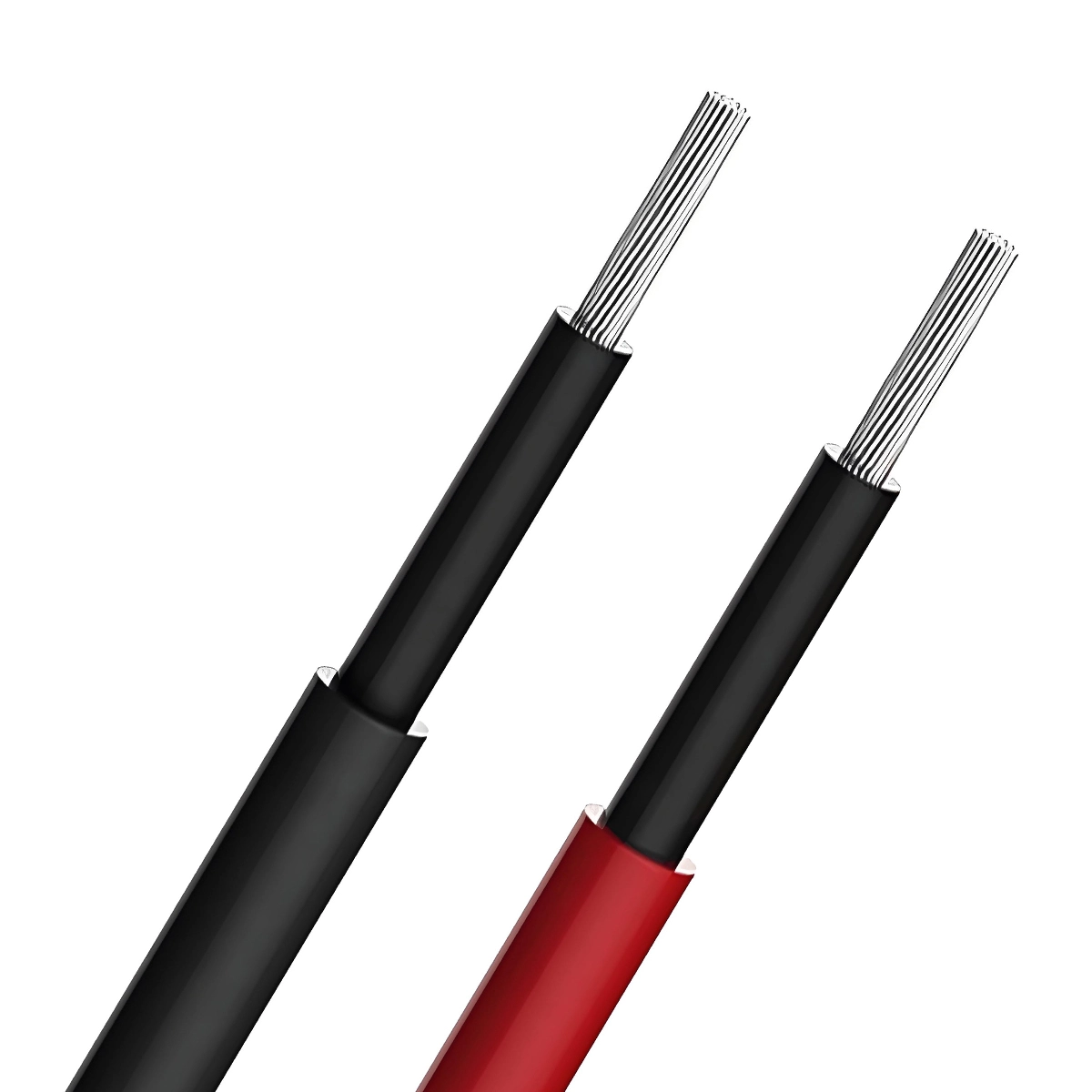

Cable ya H07V-U

- Kondakta: Shaba

- Insulation: PVC

- Voltage ya kawaida (Uo/u): 450/750V

- Voltage ya mtihani: 2.5 kV

- Joto la kawaida: 5° C. – +70° C.

- Ukadiriaji wa moto wa moto: VDE 0482-332-1-2/IEC 60332-1

- Maombi: Kwa kuweka bomba juu ya au chini ya plaster na katika ducts za ufungaji zilizofungwa na kwa wiring ya ndani ya mashine, switchgear na mifumo ya usambazaji

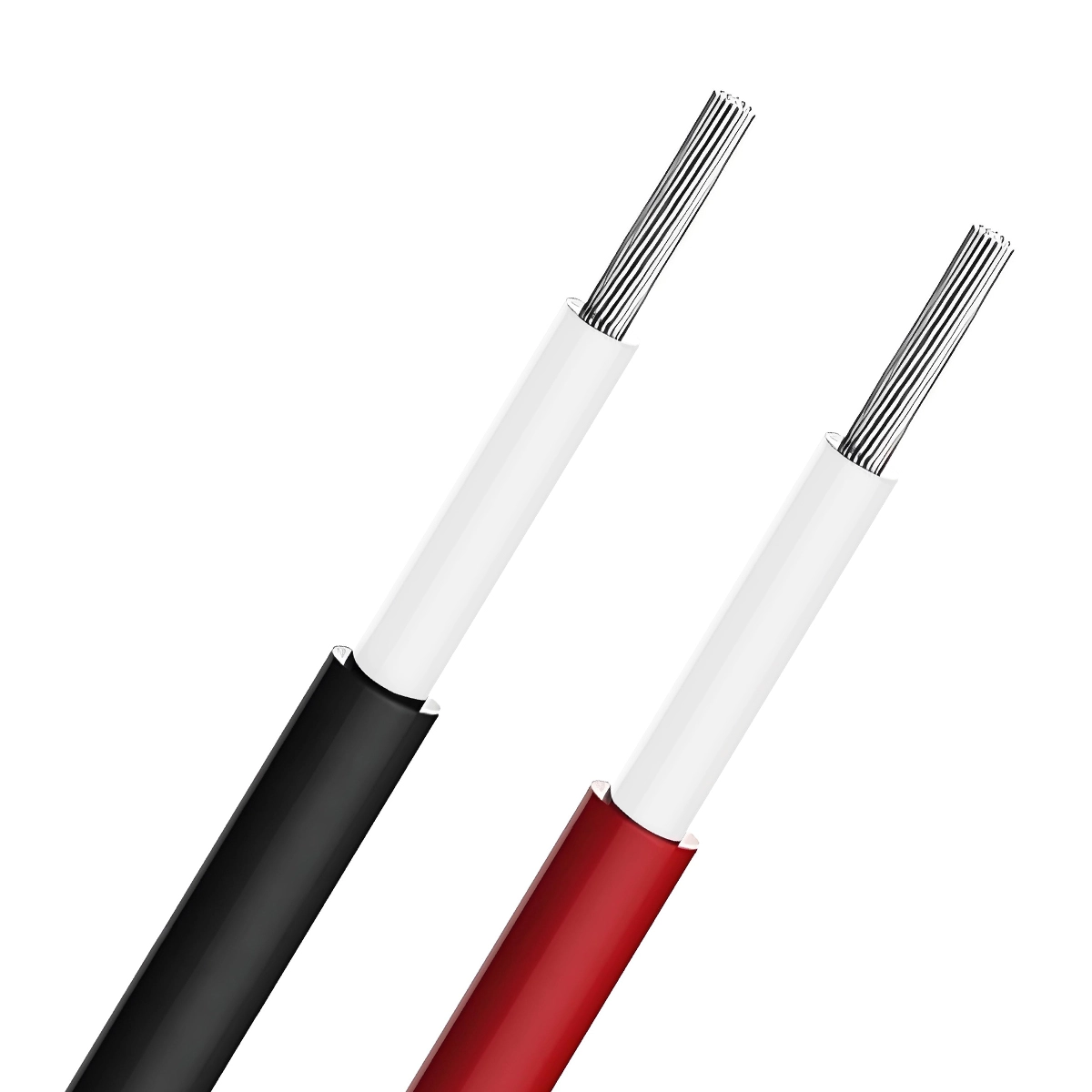

Cable ya H07RN-F

- Kondakta: Darasa 5 shaba

- Insulation: Mpira EPR

- Nyenzo za sheathing: Mpira cr

- Voltage ya kawaida (Uo/u): 450/750V

- Voltage ya mtihani: 2.5 kV

- Joto la kawaida: -25° C. – +80° C.

- Ukadiriaji wa moto wa moto: VDE 0482-332-1-2/IEC 60332-1

- Sugu ya mafuta: Katika 60811-2-1

- Ozone sugu: Ndio

- Maombi: Kwa matumizi katika mafadhaiko ya kati ya mitambo katika kavu, Maeneo ya mvua na unyevu, na pia katika hewa ya bure

Bidhaa za cable za ZMS

Maswali Yanayoulizwa Mara kwa Mara

Je! Nyaya za AC LV zinapaswa kuchaguliwaje kwa miradi ya umeme wa jua?

Wakati kituo cha umeme cha jua kiko karibu na kituo cha mzigo au yenyewe ni kizazi kilichosambazwa, Unahitaji tu kutumia nyaya za chini-voltage kuungana moja kwa moja na mtandao wa awamu tatu 400V au moja-awamu ya 230V ya usambazaji wa voltage ya chini. Kuungana na gridi ya kati au ya juu-voltage, Cables za chini-voltage lazima zitumike kwanza kuungana na transformer.

Pato la voltage ya AC na inverter kawaida huja katika viwango anuwai. Kwa mfano, Voltage ya pato la inverter ya kati inaweza kuwa 315V, 360V, 400V, Na kadhalika, Wakati voltage ya pato la inverter ya kamba inaweza kuwa 480V, 500V, 540V, 800V, Na kadhalika.

Kwa hiyo, katika mifumo ya PV, Kwa ujumla inawezekana kutumia nyaya za chini-voltage na voltage iliyokadiriwa ya 450/750V, 0.6/1 kV, au 1.8/3 kV. Kulingana na ikiwa cable imezikwa au la, Safu ya kivita inaweza kuongezwa.

Je! Nyaya za AC MV zinapaswa kuchaguliwaje kwa miradi ya nguvu ya jua?

Ikiwa mfumo wa uzalishaji wa nguvu ya Photovoltaic unahitaji kuunganishwa na gridi ya kati au ya juu-voltage, Cables za chini-voltage lazima zitumike kwanza kuungana na transformer, ambayo itaongeza voltage kwa kiwango kinachofaa. Nyaya za kati-voltage hutumiwa kupeleka nguvu kwa uingizwaji. Idadi ya nyaya za kati-voltage zinazohitajika inategemea njia ya unganisho.

Muundo wa nyota ya jadi

Katika muundo wa nyota ya jadi, Kila transformer ina mstari mmoja wa pato la kati-voltage inayounganisha kwenye uingizwaji. Muundo huu ni rahisi na moja kwa moja, na hutumiwa kawaida katika muundo wa vituo vya nguvu vya Photovoltaic. Kila cable hubeba tu nguvu ya transformer moja, Kwa hivyo maelezo ya cable ni ndogo, kupunguza gharama. Hata hivyo, Kwa kuwa kila transformer ina mstari mmoja tu unaounganisha na uingizwaji, Kuegemea sio juu sana.

Muundo wa pete moja

Muundo wa pete ya pato moja huunganisha transfoma kadhaa kwenye pete kwa kutumia nyaya, na kibadilishaji cha karibu zaidi kwa uingizwaji kimeunganishwa na uingizwaji kwa kutumia nyaya za kati-voltage. Ikilinganishwa na muundo wa pete ya pato mara mbili, Muundo wa pete ya pato moja hutumia nyaya chache za kati za voltage za jua. Hata hivyo, Kwa sababu pete nzima ina mstari mmoja tu unaounganisha na uingizwaji, Kuegemea ni chini.

Muundo wa pete ya pato mara mbili

Muundo wa pete ya pato mara mbili una mstari wa ziada unaounganisha pete na uingizwaji ukilinganisha na muundo wa pete moja. Ikiwa mstari mmoja wa pato unashindwa, Mstari mwingine unaweza kuendelea kuruhusu inverters kwenye pete kwa nguvu ya pato kwenye gridi ya taifa. Sawa na muundo wa pete ya pato moja, Kuzingatia mwelekeo wa mtiririko wakati wa kosa, nyaya zote lazima zichaguliwe kuhimili nguvu ya transfoma zote, kusababisha gharama kubwa zaidi.

Muundo wa daraja

Kabla ya muundo wa pete kupendekezwa, Muundo wa daraja mara nyingi ulitumiwa. Katika muundo huu, kulingana na muundo wa nyota, Kila jozi ya transfoma za karibu zimeunganishwa kwa kutumia nyaya za kati-voltage. Njia hii, Kila transformer ina mistari miwili inayounganisha kwa uingizwaji, Kuboresha sana kuegemea kwa mfumo. Hata hivyo, Gharama ni kubwa kwa sababu ya nyaya za ziada kati ya kila jozi ya transfoma.

Kwa vituo vya nguvu vya Photovoltaic vya ukubwa tofauti, Mchanganuo wa uteuzi wa cable hutofautiana chini ya mahitaji tofauti. Wakati wa kuchagua nyaya za kati-voltage, Ni muhimu kuzingatia kwa kina mahitaji ya lazima, Gharama, na faida za kuamua suluhisho na uamuzi mzuri zaidi.

Je! Ni kanuni gani za kuchagua nyaya za AC kwa mifumo ya nguvu ya jua?

Uteuzi wa nyaya za AC kwa miradi ya jua hufuata mahitaji ya jumla ya uteuzi wa cable, ambayo ni pamoja na kuzingatia viwango vya voltage, Kuendelea kufanya kazi sasa, Uimara wa mafuta ya mzunguko mfupi, Kushuka kwa voltage inayoruhusiwa, Uchumi wa sasa wa uchumi, na hali ya mazingira ya ufungaji. Zaidi ya hayo, Kizazi cha nguvu cha Photovoltaic kina sifa zake, Inahitaji kuzingatia nyaya ambazo zinaweza kutumika katika hali kali za mazingira kama vile joto la juu, baridi kali, na mionzi ya ultraviolet. Kwa hiyo, Sababu zifuatazo zinapaswa kuzingatiwa:

- Utendaji wa insulation ya cable

- Upinzani wa joto na urejeshaji wa moto wa cable

- Upinzani wa unyevu na kinga ya UV ya cable

- Njia za ufungaji wa kebo

- Aina ya conductor ya cable

- Uainishaji wa cable

ZMS inaweza kukupa suluhisho kamili ya cable ya jua kwa mradi wako wa umeme wa Photovoltaic, Kuwezesha sana mahitaji yako ya nguvu.

Muhtasari wa Mradi

ZMS iliungana na Nguvu ya Jimbo la Kijani (GSP), mwanzilishi katika miundombinu ya nishati mbadala, kuandaa monumental 10 Mradi wa photovoltaic wa MWP huko Kabul, Afghanistan.

ZMS ilichambua kwa kina mradi wa PV na kuutoa 1X10 na 1X6 nyaya za jua H1Z2Z2-K, 3Kebo za X300 za LV, 3Kebo za X300 za MV, pamoja na ACSR 185/30 nyaya za juu. Kukamilisha hivi vilikuwa vifaa muhimu kama viunganishi vya PV na visanduku vya zana vilivyoratibiwa kwa uangalifu.

Kujitolea kwa ZMS kwa ubora na kutegemewa kuliwezesha usakinishaji laini na ufanisi wa kufanya kazi, kuchangia miundombinu ya nishati endelevu ya kanda.

Huduma ya ZMS

Utengenezaji Uliobinafsishwa

We understand that every customer's needs are unique. Kwa hiyo, tunatoa huduma za kubinafsisha kebo za jua, kurekebisha kila undani kutoka kwa vipimo vya kebo hadi miingiliano ya unganisho kulingana na mahitaji yako mahususi ya mradi, kuhakikisha utangamano wa juu na ufanisi.

Uratibu wa Majibu ya Haraka Ulimwenguni

Kwa msaada wa mtandao wetu wa kimataifa wa vifaa, ZMS huhakikisha kwamba maagizo yako ya kebo ya photovoltaic yanafika sehemu yoyote ya dunia kwa usalama na upesi. Timu yetu ya kitaalamu ya vifaa hufuatilia kila hatua ya usafirishaji ili kuhakikisha utoaji wa bidhaa zako kwa wakati unaofaa.

Msaada wa Kiufundi

ZMS's technical support team is always on standby. Changamoto zozote za kiufundi unazokutana nazo, tunaweza kutoa majibu ya haraka na ufumbuzi wa kitaalamu, kuhakikisha matumizi ya mtumiaji bila wasiwasi.

Uzalishaji wa Kijani

Kebo zetu za jua na vifaa vinafuata kwa ukali viwango vya mazingira wakati wa mchakato wa uzalishaji, kupunguza athari zao kwa mazingira. Kwa kuchagua ZMS, sio tu unawekeza katika nyaya za ubora wa juu wa photovoltaic lakini pia unachangia maendeleo endelevu ya sayari..