Aarde Rod

Sonkrag aarde staaf word hoofsaaklik gebruik vir die aarding van sonpaneelmonterings. Daar is 'n potensiaalverskil tussen die fotovoltaïese modules en die grond, wat kan lei tot foute soos lekkasie en induktiewe koppeling in swak omgewings. Om die normale werking en veiligheid van die fotovoltaïese stelsel te verseker, dit is nodig om 'n betroubare grondstelsel te vestig.

ZMS se reeks aardstaafprodukte vir fotovoltaïese stelsels sluit kopergrondstaaf in, kopergebonde staal en gegalvaniseerde staal.

ZMS bied 'n verskeidenheid grondmateriaal in verskillende vorms, soos silindriese en plat stroke. Silindriese grondstawe is beskikbaar in verskeie style om by verskillende toepassings te pas: een puntige punt en een plat punt, een puntige punt en een skroefdraadpunt, albei kante geryg, ens.

Aansoeke:

- Aarding vir sonpaneelmonterings

- Aarding vir omsetters

- Aarding vir verspreiding bokse

- Weerligbeskermingsaarding vir stelsels

- Aarding vir kommunikasielynafskerming

ZMS Solar Earth Rod-reeks

ZMS bied gegalvaniseerde staal aan, kopergebonde staal, kaal kopergrondstawe vir normale PV-projekte. En ons kan ook koper-sinklegeringsgrondstawe en aardstawe van vlekvrye staal vervaardig, wat geskik is vir omgewings met korrosiewe media.

Gegalvaniseerde staal

Gegalvaniseerde staal is 'n tradisionele grondmateriaal met 'n sekere vlak van korrosiebestandheid en geleidingsvermoë. Alhoewel hierdie materiaal die laagste aanvanklike koste kan hê, sy korter lewensduur en hoër instandhoudingskoste kan dit op die lang duur duurder maak. ZMS se gegalvaniseerde staal grondstawe is meer geskik vir korttermyn PV projekte in gebiede met lae korrosie weerstand vereistes.

Kopergebonde staal

Kopergebonde staal kombineer die meganiese eienskappe van staal met die geleidingsvermoë en korrosiebestandheid van koper. Dit het die afgelope jare die mees gebruikte aardingskomponent in sonkragstelsels geword. ZMS gebruik 99.9% suiwer koper gegalvaniseer op 'n lae-koolstof staal kern, lei tot hoë geleidingsvermoë, hoë treksterkte, sterk weerstand teen korrosie, en maklike installasie. Die ZMS kopergebonde grondstaaf het 'n nikkellaag op die staalkern, wat dan met 'n elektrolitiese koperlaag bedek word. Hierdie proses verseker 'n permanente molekulêre binding tussen die koperlaag en die staalkern, voorkom krake selfs wanneer die staaf gebuig is.

Kaal Koper Geleier

Suiwer kopermateriaal bied uitstekende geleidingsvermoë en weerstand teen korrosie. Die geleidingsvermoë daarvan is beter as dié van kopergebonde staal. Suiwer koperaardstawe het 'n lewensduur van tot 40 jare, maar is sagter en geneig om te buig, maak hulle ongeskik vir boor in moeiliker gronde. As gevolg van sy hoër koste, suiwer koperaardstawe word tipies gebruik in situasies wat uiters hoë geleidingsvermoë vereis.

Kopergebonde staalgrondstaafspesifikasie

| Strukturele Vorm | Deursnee /mm | Lengte /mm | Gewig /kg |

| Standaard | 14 | 2500 | 3.16 |

| 14 | 3000 | 3.79 | |

| 16 | 2500 | 4.00 | |

| 16 | 3000 | 4.80 | |

| 18 | 2500 | 5.00 | |

| 18 | 3000 | 6.00 | |

| 20 | 2500 | 6.25 | |

| 20 | 3000 | 7.50 | |

| 22 | 2500 | 8.00 | |

| 22 | 3000 | 9.60 | |

| 25 | 2500 | 9.80 | |

| 25 | 3000 | 11.76 | |

| Gekombineer | 14.2 | 1200 | 1.53 |

| 14.2 | 1500 | 1.88 | |

| 17.2 | 1200 | 2.18 | |

| 17.2 | 1500 | 2.73 |

Unieke vervaardigingsproses: Gebruik van 'n koudrol- en warmtrek-produksieproses, ZMS bereik 'n metallurgiese binding tussen koper en staal. Dit laat toe dat die staaf soos 'n enkele metaal getrek kan word sonder enige ontkoppeling, afskilfering, of kraak.

Uitstekende korrosieweerstand: Die saamgestelde koppelvlak word geskep deur hoë-temperatuur sweiswerk sonder oorblyfsels, verseker dat die bindingsoppervlak vry van korrosie is. Die dik koperlaag op die oppervlak bied sterk weerstand teen korrosie en 'n lang lewensduur (oor 30 jare), die vermindering van instandhoudingskoste vir die grondnetwerk.

Verbeterde elektriese prestasie: Die buitenste laag koper van hoë gehalte bied uitstekende geleidingsvermoë, wat 'n baie laer inherente weerstand tot gevolg het in vergelyking met konvensionele materiale.

Kenmerke van ZMS Kopergebonde Staal Aarde Stawe

Breed, Veilig, en betroubare toepassing: Hierdie produk is geskik vir grondkonstruksie in verskeie grondvog, temperatuur, pH, en weerstandstoestande.

Veilige en betroubare verbindings: Die gebruik van gespesialiseerde verbindingsbuise of termietsweiswerk verseker stewige en stabiele lasse.

Maklike en vinnige installasie: Met volledige bykomstighede en maklike installasie, konstruksiespoed aansienlik verbeter kan word.

Verhoogde gronddiepte: 'n Spesiale verbindingsmetode laat die staaf tot deurdring 35 meter ondergronds, voldoen aan lae-weerstandvereistes vir spesiale toepassings. Die aardstaaf met een puntige punt en een skroefdraadpunt kan in serie verbind word deur 'n koaksiale verbinding te gebruik, wat buigsame aanpassing van die gronddiepte moontlik maak.

Lae konstruksiekoste: In vergelyking met tradisionele metodes wat suiwer koperstawe en grondstroke gebruik, die koste word aansienlik verminder.

Gereelde vrae

Waarom moet sonkragopwekkingstelsels gegrond word?

Begronding in FV-stelsels is een van die probleme wat die FV-installasiepersoneel die meeste oor die hoof sien, veral in kleinkapasiteit FV-stelsels waar daar nie veel aandag aan aarding en weerligbeskerming gegee word nie.

Egter, as aarding nie gedoen word nie, foute kan voorkom as gevolg van lae isolasie weerstand teen grond of oormatige lekstrome, kragopwekking raak en moontlik persoonlike veiligheid in gevaar stel. Daarbenewens, onbeskermde of verhoogde metaaldele is meer vatbaar vir weerlig. Sonder aarding, toerusting kan deur weerlig getref word, aansienlike skade aan die FV-kragopwekkingstelsel veroorsaak.

Aarding in FV-stelsels sluit hoofsaaklik aarding aan die sonkomponentkant in, omskakelaar kant, en verspreidingskaskant. Behoorlike aarding verhoog nie net die veiligheid van die sonnestelsel nie, maar verleng ook sy lewensduur.

Watter materiaal moet gebruik word vir aarding in fotovoltaïese stelsels?

Gegalvaniseerde staal is goedkoper, maar dit het baie gelaste lasse, wat lei tot laer konstruksiedoeltreffendheid en hoër konstruksiekoste. Suiwer koper het uitstekende geleidingsvermoë, maar is duur. Kopergebonde staal, egter, slegs koste 9.4% meer as gegalvaniseerde staal en bied 'n baie langer lewensduur. Daarom, kopergebonde staal elektriese aardstawe word tipies gekies as die primêre grondmateriaal in sonkragstelsels.

| Aarde Staaf Materiaal | Gegalvaniseerde staal | Kaal koper | Kopergebonde staal |

| Weerstand Ω.mm | 1.7×10^-7 | 1.73×10^-8 | Hang af van die dikte van die koperlaag |

| Digtheid g/cm3 | 7.8 | 8.9 | – |

| Korrosieweerstand | 0.065 mm/a | Korrosietempo gelykstaande aan 1/7 van gegalvaniseerde staal | Vergelykbaar met koper voor vernietiging van die koperlaag |

| Proses Kenmerke | Groot grootte materiaal, hoë sweisvereistes, komplekse konstruksie | Enkel proses, vinniger as puntsweiswerk | Enkel proses, vinniger as puntsweiswerk |

| Bedryfslewe | 7 – 13 | > 40 | > 40 |

| Koste | Laag | Hoog | Medium |

Watter spesifikasies van aardstawe word algemeen gebruik?

Kopergebonde staal

In fotovoltaïese kragstelsels, die horisontale aardingliggaam van kopergebonde staalgrondmateriaal gebruik gewoonlik Φ10-Φ12 kopergebonde ronde staal, met 'n vervaardigingslengte tipies van 100 meter per katrol. Die aardelektrodes gebruik Φ14 of Φ17.2 kopergebonde staalstawe.

Verbinding metode: Termiet sweiswerk (geen eksterne krag of asetileen nodig nie), gebruik suiwer koper vir voegmateriaal, met geen behoefte aan korrosiemaatreëls by die sweispunte nie.

Gegalvaniseerde staal

In tradisionele grondroosters, horisontale aardliggame gemaak van warm gegalvaniseerde staal is oor die algemeen ontwerp met spesifikasies van 50X5 of 60X6 gegalvaniseerde plat staal, met 'n vervaardigingslengte van 6 meter per stuk. Vertikale aardelektrodes gebruik 50X5 warm gegalvaniseerde hoekstaal of Φ50 gegalvaniseerde staalpype, met 'n aardingselektrode lengte van 2.5 meter per stuk.

Verbinding metode: Elektriese sweiswerk, met die sweispunte wat teen-roesbehandeling benodig, soos twee lae anti-roesverf en een laag asfaltverf.

Kaal koper

Vir suiwer kopergrondmateriaal, die horisontale aardingliggaam gebruik gewoonlik 25×4, 40×4, 50×5, of 60×6 mm koperstroke, of S70/S95/S120/S150/S185/S240 mm kaal koperdrade. Die vertikale aardliggaam gebruik tipies 16×2500 mm of 20×2500 mm koperstawe, of 50×3000 mm of 55×2500 mm suiwer koper elektrolitiese ioon aardelektrodes.

Verbinding metode: Termiet sweiswerk, brand modder smelt sweiswerk, of warmsmeltsweiswerk.

Hoe moet aardstawe in fotovoltaïese stelsels geïnstalleer word?

Tydens konstruksie, die installering van 'n grondstaaf is baie buigsaam en kan by die spesifieke toestande op die terrein aangepas word. Verskeie metodes kan gebruik word, soos om die elektriese grondstawe direk met swaar hamers of elektriese hamers in die grond in te dryf. In komplekse grondtoestande waar die staaf nie ingedryf kan word nie, 'n gat kan eers geboor word voordat die grondstaaf geïnstalleer word.

In eenvormige grondtoestande, as 'n swaar hamer vir installasie gebruik word en 'n enkele staaf aandryf, dit is raadsaam om 'n boorpunt te installeer (slagvaste bout) op die puntige punt van die staaf om skade aan die koperlaag te voorkom wanneer die staaf diep gedryf word. Vir dieper grond, veelvuldige stawe kan verbind word met behulp van verbindings om die verlangde lengte te bereik, goeie elektriese verbinding te verseker.

In gevalle waar diep boor moeilik of onmoontlik is, boorgereedskap kan gebruik word om rotse binne te dring. Na boor, daar is twee metodes om die grondstawe te installeer:

1. Koppel die stawe aan die verlangde lengte met behulp van verbindings. Sodra dit tot die beoogde diepte geboor is, vul die gat met 'n weerstandsverminderende middel en voeg water by totdat die gaatjie gevul is.

2. Koppel die stawe aan die verlangde lengte met behulp van verbindings. Na boor tot die beoogde diepte, meng die weerstandsverminderende middel met water en gooi dit in die gat om die staaf heeltemal te omhul.

Watter aarding word in sonkragstelsels vereis?

Komponent-kant aarding:

- Module Raam Aarding: Die aluminiumraam van die module wat met die berg in aanraking kom, beteken nie effektiewe aarding nie. Die aardingsgat van die module moet aan die berg gekoppel word vir effektiewe aarding. Die aardingsgate van die modules word tipies vir touverbindings gebruik, met die aardingsgate aan albei kante wat aan die metaalmontering gekoppel is.

- Berggronding: Gewoonlik, ronde staal, gegalvaniseerde staalstawe, of kopergebonde staalstawe word vir aarding gebruik, met die aardingsweerstand wat vereis word om nie groter as 4Ω te wees nie.

Omskakelaar-kant aarding:

- Operasionele gronding: Die PE-terminaal van die omskakelaar is aan die PE-rail in die verspreidingskas gekoppel, wat deur die verspreidingskassie gegrond is.

- Beskermende aarding: Die aardingsgat van die omskakelaar-onderstel word gebruik vir herhaalde aarding om die omskakelaar en die veiligheid van operateurs te beskerm. Die beskermende aarding van die omskakelaar-onderstel kan óf 'n aparte aardelektrode gebruik óf een deel met die verspreidingskas.

Verspreiding Box-kant aarding:

- Weerligbeskerming Aarding: Weerligbeskerming aan die AC-kant bestaan uit versmeltings of stroombrekers en toerusting vir stootbeskerming (SPD). Die onderste punt van die SPD is aan die aardingrail van die verspreidingskas gekoppel.

- Boksgronding: Volgens regulasies, die metaalraam en basisstaal van die verdeelboks moet geaard wees of aan neutraal gekoppel wees. Die kasdeur en die kasliggaam benodig kruisverbinding om betroubare aarding te verseker.

Projek Hoogtepunt

ZMS het kragte saamgesnoer met Groen Staatsmag (GSP), 'n pionier in hernubare energie-infrastruktuur, om 'n monumentale toe te rus 10 MWP fotovoltaïese projek in Kaboel, Afghanistan.

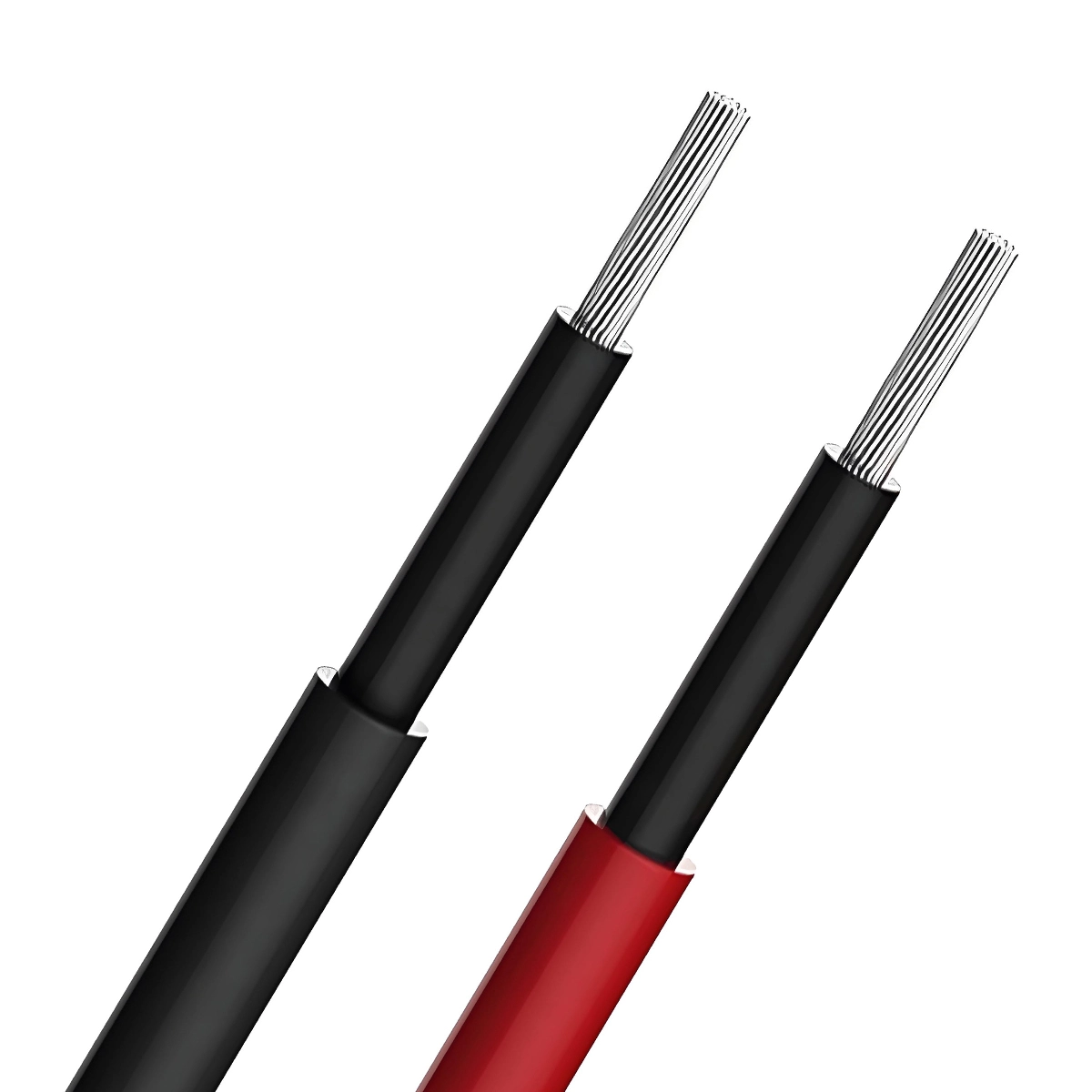

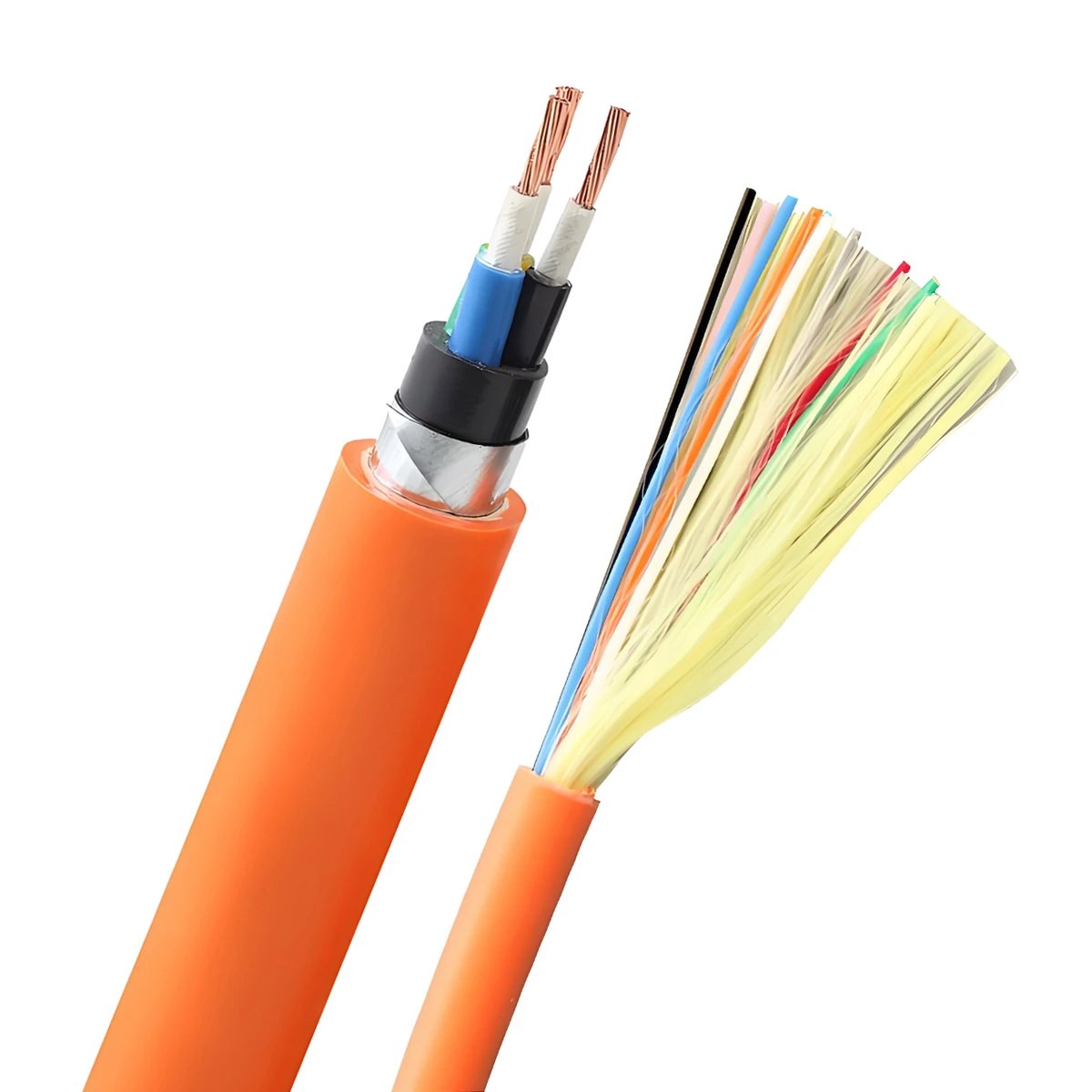

ZMS het die FV-projek omvattend ontleed en dit voorsien 1X10 en 1X6 sonkragkabels H1Z2Z2-K, 3X300 LV kabels, 3X300 MV kabels, sowel as ACSR 185/30 oorhoofse kabels. As aanvulling hierop was noodsaaklike bykomstighede soos PV-verbindings en noukeurig saamgestelde gereedskapkaste.

ZMS se verbintenis tot kwaliteit en betroubaarheid het gladde installasie en operasionele doeltreffendheid vergemaklik, by te dra tot die streek se volhoubare energie-infrastruktuur.

ZMS diens

Pasgemaakte vervaardiging

We understand that every customer's needs are unique. Daarom, ons bied persoonlike sonkragkabel-aanpassingsdienste, pas elke detail van kabelspesifikasies tot verbindingskoppelvlakke aan volgens jou spesifieke projekvereistes, verseker maksimum verenigbaarheid en doeltreffendheid.

Globale vinnige reaksie-logistiek

Met die ondersteuning van ons globale logistieke netwerk, ZMS verseker dat jou fotovoltaïese kabelbestellings enige uithoek van die wêreld veilig en stiptelik bereik. Ons professionele logistieke span monitor elke stadium van vervoer om tydige aflewering van u goedere te verseker.

Tegniese Ondersteuning

ZMS's technical support team is always on standby. Watter tegniese uitdagings jy ook al teëkom, ons kan vinnige antwoorde en professionele oplossings verskaf, verseker 'n kommervrye gebruikerservaring.

Groen Produksie

Ons sonkragkabels en bykomstighede voldoen streng aan omgewingstandaarde tydens die produksieproses, hul impak op die omgewing te verminder. Deur ZMS te kies, jy belê nie net in fotovoltaïese kabels van hoë gehalte nie, maar dra ook by tot die volhoubare ontwikkeling van die planeet.