Communication & Control Cable

ZMS manufactures a comprehensive range of communication & control cable for solar system. These high-quality cables ensure seamless data transfer and efficient system management, as well as precise power distribution and operational control.

Communication cables in a solar power system facilitate data transfer between components such as solar panels, inverters, and monitoring systems, enabling real-time performance monitoring, remote control, and diagnostics. ZMS can provide singlemode or multimode fiber optic cables with the required terminations as well as shielded twisted pair cables.

Control cables manage power distribution and operational control within a solar power system by transmitting control signals to components like inverters, trackers, and relays. They ensure proper execution of operational commands, safety mechanisms, and synchronization of multiple system parts. ZMS control and instrumentation cables can maintain the efficiency and reliability of PV systems by coordinating power regulation and providing protective functions.

ZMS Communication Cable

Single Mode Fiber Optic Cable

ZMS’s single mode fiber optic cables are engineered for long-distance data transmission with minimal signal loss, making them ideal for connecting SMU loops to inverter stations and linking inverter stations to SCADA rooms. These cables provide high bandwidth and low attenuation, ensuring reliable and high-speed communication essential for real-time monitoring and control in solar energy systems.

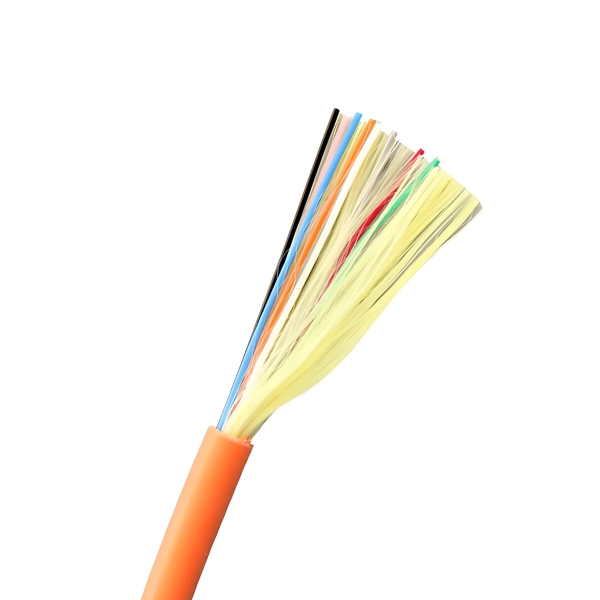

Multimode Fiber Optic Cable

ZMS offers multimode fiber optic cables designed for shorter-distance data transmission within solar energy systems. These cables are perfect for connecting various components within an inverter station, providing robust performance and high data transmission rates. The multimode design allows multiple signals to be sent simultaneously, enhancing the efficiency and reliability of your solar power system.

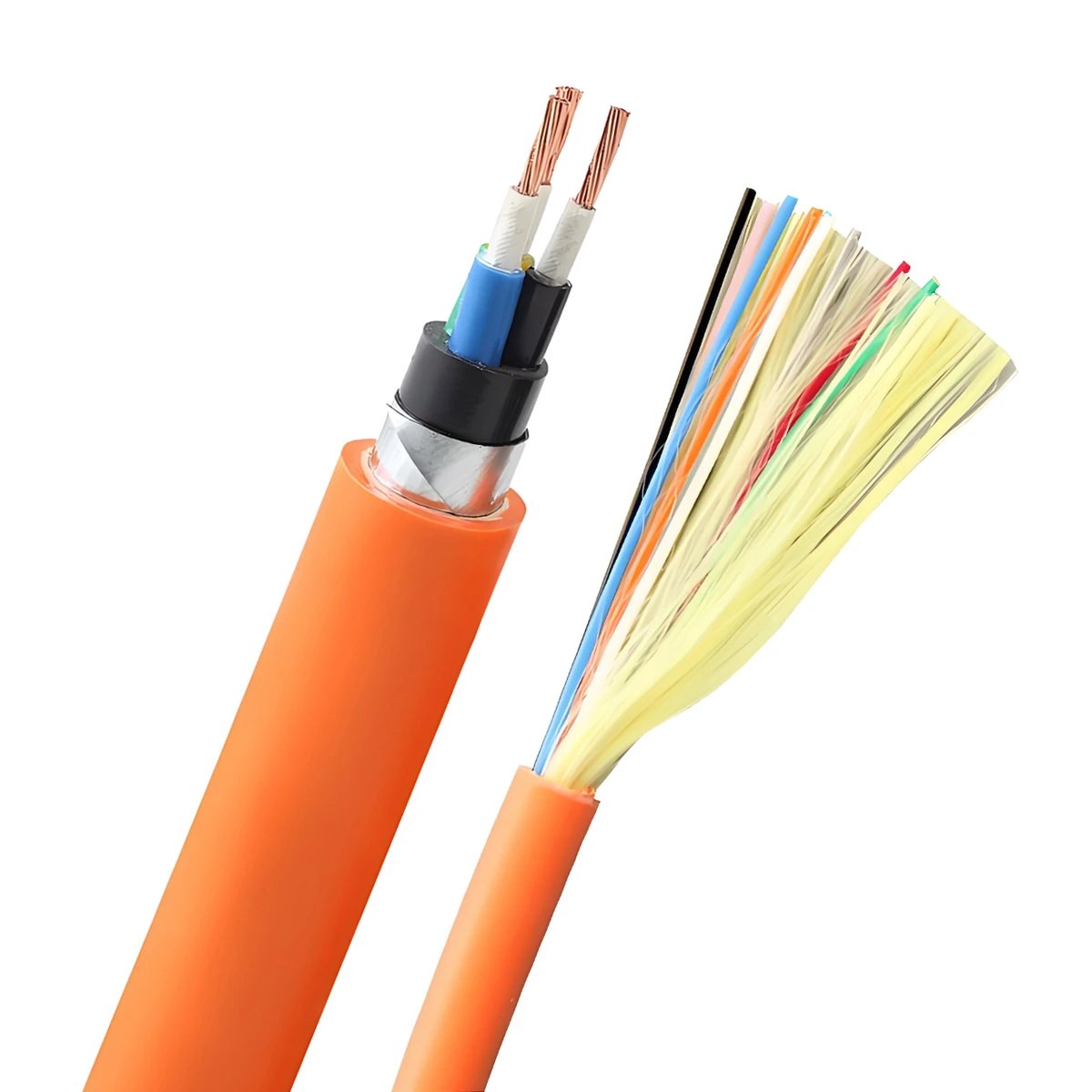

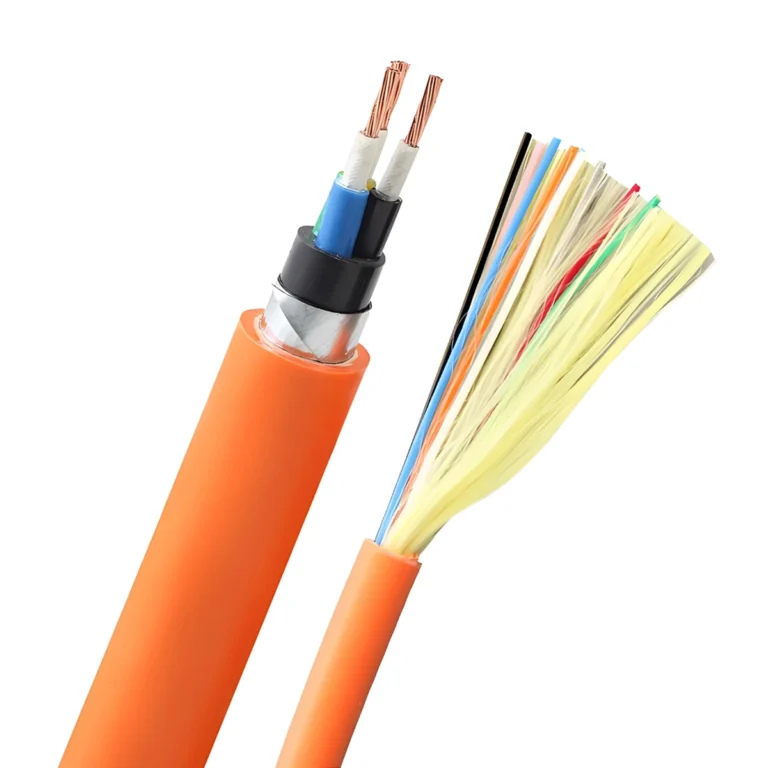

Armored Fiber Optic Cable

Our armored fiber optic cables are built to withstand harsh environmental conditions, providing added protection against physical damage and ensuring uninterrupted data transmission. These cables are ideally suited for outdoor installations where extra durability is required as well as buried installations.

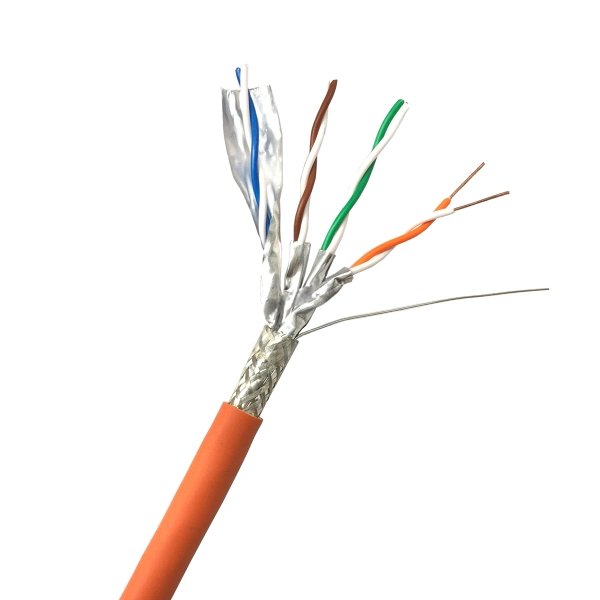

Twisted Pair Cable

ZMS’s twisted pair cables offer a cost-effective solution for communication between solar system components. While twisted pair cables have a limited bandwidth and distance and are susceptible to signal interference. Our cables feature a specialized shield design to minimize electromagnetic interference. With optional terminations, they are versatile and easy to install.

ZMS Control Cable

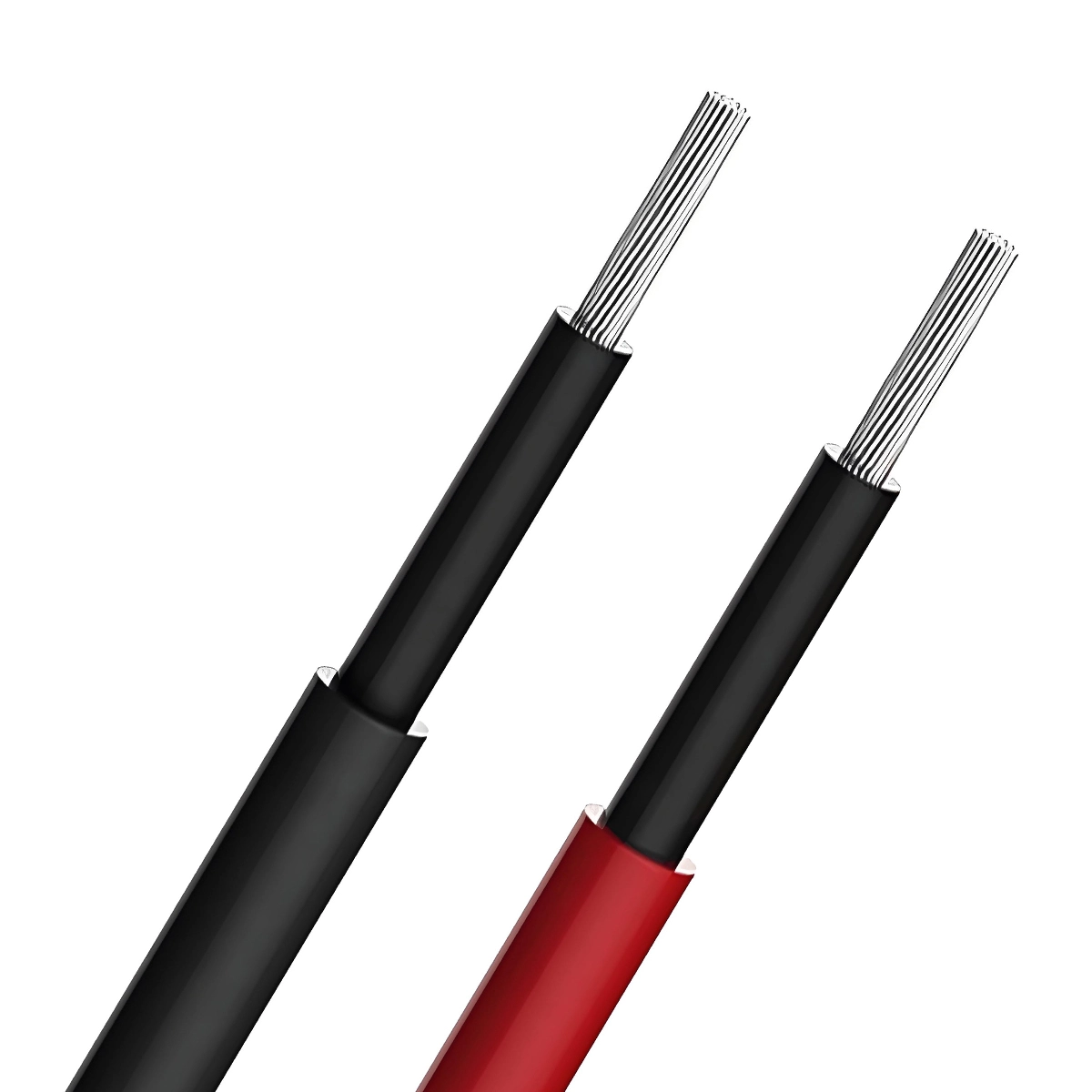

Multi-core Control Cable

Quality control cables supplied by ZMS ensure precise power distribution and operational control within solar energy systems. Constructed with copper conductors, shielding, and XLPE insulation, these cables offer excellent electrical performance and durability.

- Conductor: Copper

Number of Cores: Customizable according to specific application requirements; common core counts include 2, 3, 4, 5, 7, 10, 12, 14, 16, 19, and 24 - Insulation Material: PVC/XLPE

- Shielding: Copper-plastic composite tape/Aluminum-plastic composite tape/Copper wire braid

- Sheathing Material:: PVC

- Bending Radius: 20D (single core), 15D (multi-core)

- Standards: IEC 60502, IEC 60332-3

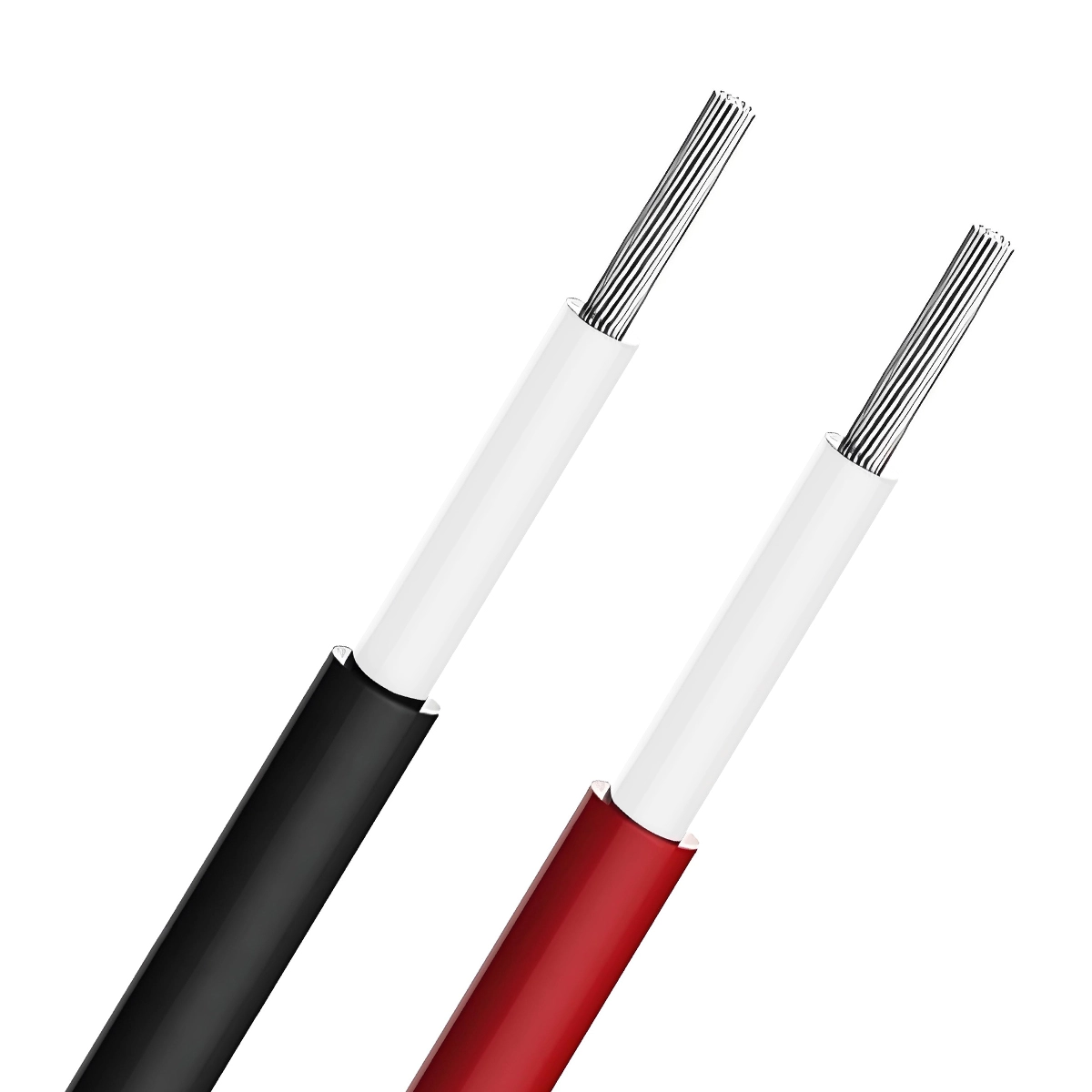

Instrumentation Cable

Instrumentation cables made by ZMS feature high-quality shielding and PVC insulation to provide solar systems with excellent protection against electromagnetic interference, ensuring accurate and clear data transmission.

- Conductor: Copper/Tinned Copper

- Insulation: PE/PVC/XLPE

- Shielding: Aluminum-plastic composite tape

- Sheathing Material: PVC / LSZH

- Operating Temperature: 0˚C to +50˚C

- Standards: BS 5308, BS EN 60228, IEC 60332-1

FAQ

Do Communication Cables Affect the Accuracy of Solar Power Generation System Counting?

In a solar power generation system, the primary role of communication cables is to transmit control signals and monitoring data, such as power output, system status, fault alarms, and other information. These cables do not directly participate in the transmission of electrical energy. Therefore, communication cables themselves do not directly affect the accuracy of the counting in a solar power generation system.

However, if communication cables experience faults (such as signal attenuation, interference, or disconnections), it may lead to the monitoring system being unable to accurately receive or transmit data, thereby affecting the precision and timeliness of system monitoring. For example, data transmission delays or errors might prevent maintenance personnel from promptly understanding the actual operational status of the power generation system or lead to inaccurate data recording, thus impacting the statistics and analysis of power generation.

Therefore, while communication cables do not affect the actual production of electrical energy, they are crucial for the effective management and maintenance of the system. This indirectly relates to the overall performance evaluation and efficiency optimization of the solar power generation system. Ensuring the quality and proper maintenance of communication cables is essential for maintaining reliable monitoring and efficient operation of the solar power generation system.

What Types of Cables Are Needed for Solar Power Systems?

As a crucial component of sustainable energy solutions, the safe and efficient operation of solar power generation systems relies on the appropriate configuration and use of various specialized cables. The types of cables required in a solar power generation system include the following:

Solar DC Cable

These cables are specifically designed for connecting photovoltaic modules (solar panels) and for power transmission between modules to the DC combiner box. Given their direct exposure to outdoor environments, they must possess the following characteristics:

- UV Resistance: To prevent performance degradation due to prolonged sun exposure.

- Weather Resistance: To withstand various weather conditions, including extreme temperatures, humidity, and wind-blown sand.

- Salt Spray Corrosion Resistance: Suitable for coastal areas to prevent salt damage.

- Flame Retardancy: To reduce fire risks and enhance system safety.

- Mechanical Strength: To endure installation and environmental pressures without being easily damaged.

AC Cable

AC cables are used at the inverter output end to transmit the converted AC power to the AC distribution board or directly into the grid. These cables need to meet grid connection standards and possess good insulation properties and heat resistance to ensure safe and efficient power transmission.

Data Communication Cable

In a solar power generation system, data communication cables act as the information bridge. They not only transmit the electrical data generated by the photovoltaic array but also convey real-time status information of inverters and other monitoring equipment to the central monitoring system via wired or wireless networks (including fiber optics) for system optimization and fault diagnosis.

Control Cable

Control cables are used to connect controllers, inverters, and other auxiliary equipment within the system, ensuring automated control and effective monitoring. These cables need to have good signal transmission stability and anti-interference capabilities to ensure accurate execution of control commands.

Grounding Cable

Grounding cables play a critical role in the safety protection of the entire solar power generation system. They provide a low-resistance path to quickly discharge lightning currents or system fault currents, preventing electric shocks and equipment damage, thereby ensuring the safety of personnel and equipment.

Overhead Cable

In certain installation scenarios, such as long-distance transmission or terrain constraints, overhead cables are used for grid connection of the solar power generation system. These cables need to be specially designed to resist external physical damage and climatic factors while maintaining good conductivity and mechanical strength.

When selecting these solar cables, it is essential not only to consider their characteristics and applicable environments but also to ensure that all cables and accessories comply with local electrical safety standards and industry regulations to ensure the long-term stable operation and compliance of the solar power generation system.

What Percentage of the Total Construction Cost Do Cables Represent in a Photovoltaic Power Station?

The cost of cables in a photovoltaic (PV) power station typically represents around 10% of the total construction cost. This percentage can vary based on several factors such as the scale of the project, equipment selection, regional differences, and market fluctuations. According to some estimates:

- Photovoltaic modules (solar panels) account for approximately 50% of the total equipment cost.

- Inverters and other electrical equipment account for about 10%.

- Cables and mounting structures each account for around 10%.

Therefore, cable costs generally make up about 10% of the total construction cost. However, this is a rough estimate, and the actual proportion may vary depending on the specific budget and material prices of a project. Additionally, with advancements in technology and market changes, this percentage may be subject to adjustments.

ZMS can provide comprehensive and customized cable solutions and integrated quotation services for your various solar power projects. Feel free to contact us!

Project Highlight

ZMS joined forces with Green State Power (GSP), a pioneer in renewable energy infrastructure, to equip a monumental 10 MWP photovoltaic project in Kabul, Afghanistan.

ZMS comprehensively analyzed the PV project and provided it with 1X10 and 1X6 solar cables H1Z2Z2-K, 3X300 LV cables, 3X300 MV cables, as well as ACSR 185/30 overhead cables. Complementing these were vital accessories like PV connectors and meticulously curated toolboxes.

ZMS’s commitment to quality and reliability facilitated smooth installation and operational efficiency, contributing to the region’s sustainable energy infrastructure.

ZMS Service

Customized Manufacturing

We understand that every customer's needs are unique. Therefore, we offer personalized solar cable customization services, tailoring every detail from cable specifications to connection interfaces according to your specific project requirements, ensuring maximum compatibility and efficiency.

Global Rapid Response Logistics

With the support of our global logistics network, ZMS ensures that your photovoltaic cable orders reach any corner of the world safely and promptly. Our professional logistics team monitors every stage of transportation to ensure timely delivery of your goods.

Technical Support

ZMS's technical support team is always on standby. Whatever technical challenges you encounter, we can provide rapid responses and professional solutions, ensuring a worry-free user experience.

Green Production

Our solar cables and accessories strictly adhere to environmental standards during the production process, minimizing their impact on the environment. By choosing ZMS, you are not only investing in high-quality photovoltaic cables but also contributing to the sustainable development of the planet.