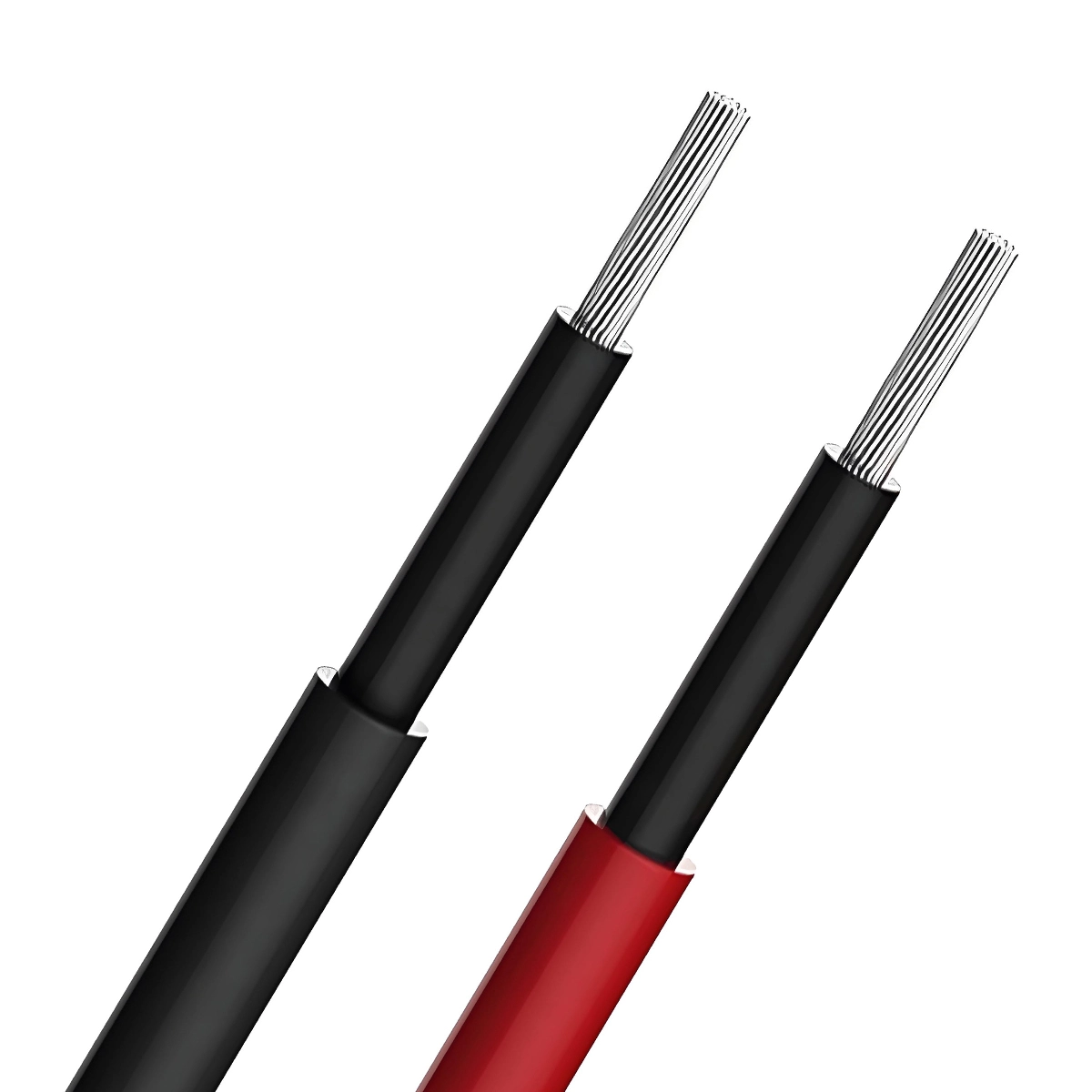

Overhead Cable

Overhead cable can integrate the electricity generated by solar power systems into the grid. ZMS can provide the necessary overhead cables such as ACSR, ACAR, AAC, and AAAC for various photovoltaic power generation projects.

In grid-connected solar power systems, the type of overhead cable used depends on specific installation requirements, such as voltage level, current-carrying capacity, mechanical strength, and environmental conditions.

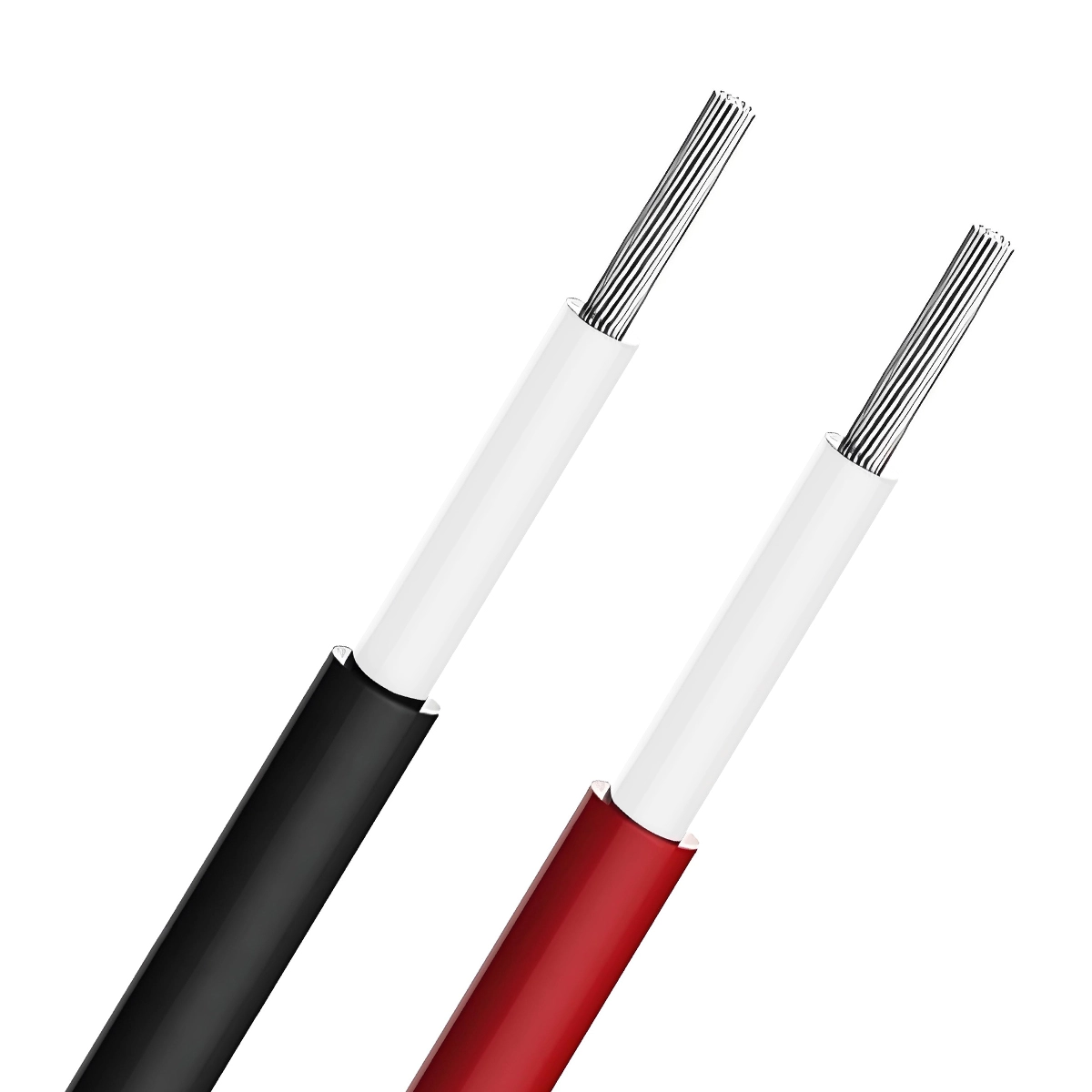

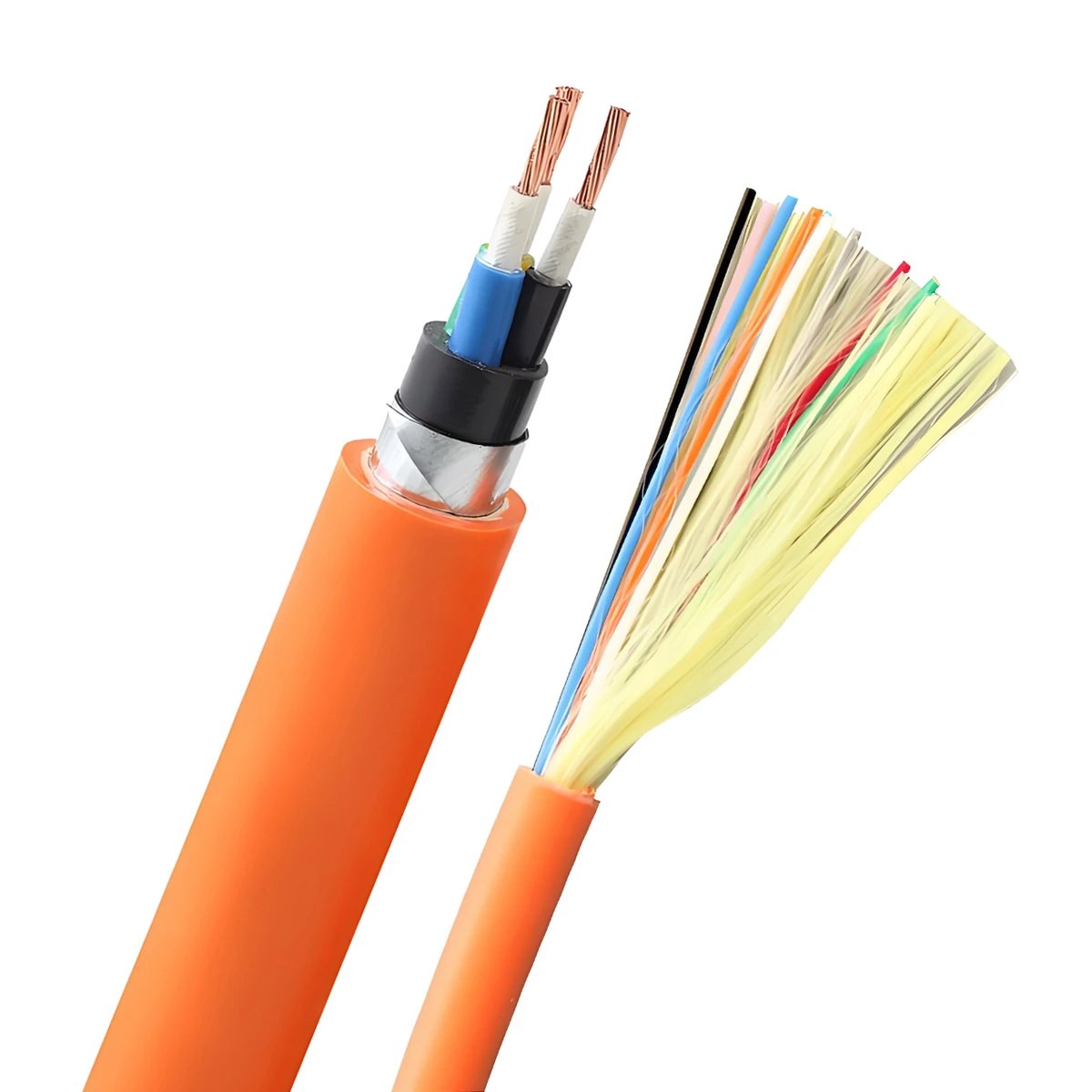

From DC cables used for solar panels to AC cables used for inverter output, and finally to the overhead or underground cables that connect to the grid, ZMS’s professional team will comprehensively consider the scale of the solar project, geographical location, environmental conditions, and grid connection requirements to tailor the most suitable power cabling solution for you.

AAC (All Aluminum Conductor)

Structure:

AAC is composed of one or more strands of aluminum wire. These conductors are made from electrolytically refined aluminum with a minimum purity of 99.7%. The construction follows the standards of EN 60889 Type AL1 according to BS 215.

Characteristics:

AAC conductors are highly conductive and primarily used in urban areas for low, medium, and high voltage overhead lines where spans are short. They exhibit excellent corrosion resistance, making them ideal for coastal regions.

Standards:

ASTM B 230, ASTM B 231, TS IEC 1089, DIN48201, and BS 215.

AAAC (All Aluminum Alloy Conductor)

Structure:

AAAC cables consist of aluminum alloy wires concentrically stranded. They are made from a magnesium-silicon-type aluminum alloy (alloy 6201) with magnesium content between 0.6-0.9% and silicon content between 0.5-0.9%. These conductors are designed to be highly conductive with a minimum of 53% IACS.

Characteristics:

AAAC conductors offer improved strength, weight, and electrical properties compared to AAC and ACSR. They have better vertical tensile properties and enhanced corrosion resistance, making them suitable for medium and high voltage transmission lines. Their lower ice-breaking loads are advantageous in regions with low ice and wind loads. AAAC conductors are customizable based on specific application needs and customer requirements.

Standards:

ASTM B 230, ASTM B 231, TS IEC 1089, DIN48201, and BS 215.

ACSR (Aluminum Conductor Steel Reinforced)

Structure:

ACSR conductors consist of several aluminum and galvanized steel conductors stranded in concentric layers. The core is made of galvanized steel, which may consist of 1, 7, or 19 wires, and is surrounded by aluminum strands. The core wire for ACSR is available with class A, B, or C galvanizing.

Characteristics:

ACSR cables are versatile and suitable for transmission lines across all voltage levels, including challenging terrains such as rivers and ravines. By adjusting the proportions of aluminum and steel, specific properties for various applications can be achieved. Increasing the steel content enhances antistatic properties, while more aluminum content increases current carrying capacity.

Standards:

ASTM B 230, ASTM B 231, TS IEC 1089, DIN48201, and BS 215.

ZMS Cable Products

FAQ

Which Overhead Cable to Use in Solar Power Systems?

In grid-connected photovoltaic power generation systems, once the generated DC power is converted to AC power by the inverter and integrated into the AC grid, power transmission is often carried out via overhead lines. Typically, the grid connection process of photovoltaic power generation systems can occur in the following scenarios:

Direct Connection

For small distributed photovoltaic power generation systems, such as residential rooftop photovoltaics, the DC power can be directly converted to AC power through the inverter and then connected to the low-voltage grid via distribution lines. In this case, underground low-voltage cables and overhead insulated cables like ABC cables can be used.

Connection through Box Transformers or Substation Integration

Medium or commercial-scale photovoltaic power stations may use box-type substations (box transformers) to convert the DC power generated into AC power suitable for grid integration through the inverter, and then step up the voltage through the box transformer to match the voltage level of the overhead grid, before connecting to overhead lines.

Large-scale ground-mounted photovoltaic power stations typically require a transformer to step up the voltage to a higher level for efficient transmission. In this case, the power is directly connected to a substation, which then distributes it to high-voltage or ultra-high-voltage overhead grids.

In these two scenarios, if the distance from the power station to the grid connection point is relatively short and the load is not large, AAC cable could be an economical choice. For medium distances or where better physical performance is required, AAAC cable may be a better option. For long-distance transmission or where special cable strength requirements are needed, especially when overhead lines need to cross complex terrain or withstand extreme weather conditions, ACSR conductor will be the most suitable choice.

What Are the Differences between AAC, AAAC, and ACSR Cables?

AAC: All-Aluminum Conductor (AAC) cables are relatively low-cost, lightweight, and have good conductivity, making them suitable for short-distance transmission and light load conditions. However, their strength is relatively low, with limited tensile capability, which might not be suitable for long distances or situations requiring high mechanical strength.

AAAC: Compared to AAC, All-Aluminum Alloy Conductor (AAAC) cables have higher mechanical strength, better tensile strength, and corrosion resistance while maintaining good conductivity. This makes AAAC more suitable for medium-length transmission lines and environments with certain mechanical strength requirements, although the cost may be slightly higher than AAC.

ACSR: Aluminium Steel Reinforced Conductor (ACSR) cables combine the excellent conductivity of aluminum with the high strength of steel. They are particularly suitable for long-distance, heavy load, or transmission lines with strict mechanical strength requirements. ACSR cables can effectively withstand storms, snow loads, and line tension but are relatively more expensive.

In solar power generation systems, the choice between AAC, AAAC, or ACSR cables mainly depends on the system’s design, transmission distance, load requirements, and cost-benefit analysis. For short-distance and light load power transmission, AAC can be selected. For medium distances or where better physical performance is needed, AAAC is suitable. For long-distance transmission or complex environmental conditions, ACSR is usually the preferred choice.

What Factors Should Be Considered When Selecting Overhead Cables for PV Power Systems?

When selecting overhead lines for photovoltaic power generation systems, several key factors must be considered to ensure the system’s safety, efficiency, and long-term reliability:

Environmental Conditions: Evaluate the climate conditions of the installation site, including wind speed, rainfall, temperature range, ice load, and salt spray corrosion. Choose overhead cable types and specifications that can withstand these environmental impacts.

Voltage Level and Current Carrying Capacity: Select cables with the appropriate voltage level and sufficient current carrying capacity based on the output power of the photovoltaic power generation system and grid connection requirements to ensure safe and lossless power transmission.

Conductor Type: Consider using AAC, AAAC, or ACSR conductors based on transmission distance, load requirements, and cost-benefit analysis. For low-voltage transmission, use insulated cables such as PVC or XLPE insulated cables.

Route Planning: Follow overhead line route selection principles, such as shortening the path as much as possible, reducing corners, avoiding potential obstacles and hazardous areas, ensuring line stability, and ease of maintenance.

Mechanical Strength and Durability: Choose cables that can withstand tension, wind pressure, and other mechanical stresses. For long-distance transmission or harsh environments, high mechanical strength ACSR may be the better choice.

Installation and Maintenance: Consider the ease of installation, maintenance costs, and potential future expansion needs. Choose cable types that are easy to install and maintain.

Safety: Ensure that overhead cables and accessories comply with local safety standards and regulations, including lightning protection and grounding requirements, to prevent electrical fires and electric shock risks.

Cost-Effectiveness: Conduct a comprehensive evaluation of the costs and benefits of different overhead power cable solutions, including initial investment, operational maintenance costs, and expected lifespan, to make the most economical and reasonable decision.

Compatibility and Compliance: Ensure that the selected overhead cable matches the output power of the photovoltaic system and meets national or regional electrical safety standards and grid connection requirements.

Future Expandability: Consider the potential expansion of the solar system. Choose cables with some redundancy to facilitate convenient upgrades when increasing generation capacity or improving the system in the future.

The final cable selection should be based on the specific project’s actual situation, including environmental factors, budget constraints, safety standards, and grid requirements. ZMS can provide a comprehensive cable solution for your solar power generation project, helping to simplify the project implementation process, shorten construction periods, and effectively control costs.

Project Highlight

ZMS joined forces with Green State Power (GSP), a pioneer in renewable energy infrastructure, to equip a monumental 10 MWP photovoltaic project in Kabul, Afghanistan.

ZMS comprehensively analyzed the PV project and provided it with 1X10 and 1X6 solar cables H1Z2Z2-K, 3X300 LV cables, 3X300 MV cables, as well as ACSR 185/30 overhead cables. Complementing these were vital accessories like PV connectors and meticulously curated toolboxes.

ZMS’s commitment to quality and reliability facilitated smooth installation and operational efficiency, contributing to the region’s sustainable energy infrastructure.

ZMS Service

Customized Manufacturing

We understand that every customer's needs are unique. Therefore, we offer personalized solar cable customization services, tailoring every detail from cable specifications to connection interfaces according to your specific project requirements, ensuring maximum compatibility and efficiency.

Global Rapid Response Logistics

With the support of our global logistics network, ZMS ensures that your photovoltaic cable orders reach any corner of the world safely and promptly. Our professional logistics team monitors every stage of transportation to ensure timely delivery of your goods.

Technical Support

ZMS's technical support team is always on standby. Whatever technical challenges you encounter, we can provide rapid responses and professional solutions, ensuring a worry-free user experience.

Green Production

Our solar cables and accessories strictly adhere to environmental standards during the production process, minimizing their impact on the environment. By choosing ZMS, you are not only investing in high-quality photovoltaic cables but also contributing to the sustainable development of the planet.