ZMS Solar Cable Products

ZMS offers comprehensive and customized solar cable solutions for your PV project, including DC cables for solar panels, AC cables for power transmission, control and communication cables for system monitoring, and overhead cables for grid connections.

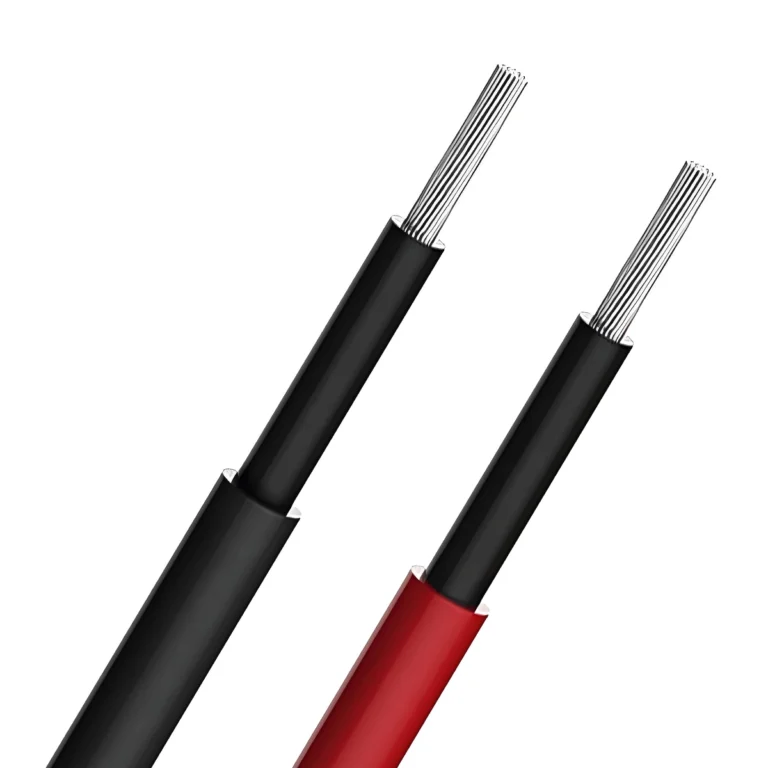

ZMS H1Z2Z2-K cable designed to the latest EN 50618 represents the pinnacle of safety and flexibility for solar systems. This type of solar power cable is made of LSZH material with excellent UV and ozone resistance to ensure reliability and durability in all weather conditions.

The PV1-F solar cable is renowned for its exceptional durability and adaptability. As the classic cable for solar panel, its robust construction ensures lasting performance, making it a trusted choice for efficient solar energy systems.

ZMS provide a diverse selection of solar panel extension cables, including compatible MC4 cables, Anderson extension leads, and and others with various connectors and adapters. With universal compatibility, our solar panel extension cord is the reliable choice for your solar energy system.

ZMS offers a wide range of low-voltage and medium-voltage AC cables for grid connection of photovoltaic power generation, including H07V-U Cable, H07RN-F Cable, NYY Cable, N2XSY Cable, NA2XY Cable, etc.

Essential for any solar power system, our solar panel grounding wire provides effective grounding, protecting your solar installations against lightning strikes and electrical surges.

A wide range of materials and shapes of earth rods of ZMS can be used for the grounding of solar panel supports as well as for the grounding of inverters, distribution boxes and other system equipments.

ZMS manufactures high quality ACSR, ACAR, AAC, AAAC and other overhead cables for grid connection. Based on the size of PV project, geographic location, environmental conditions and grid access requirements, we can develop the most suitable power cabling solution for you.

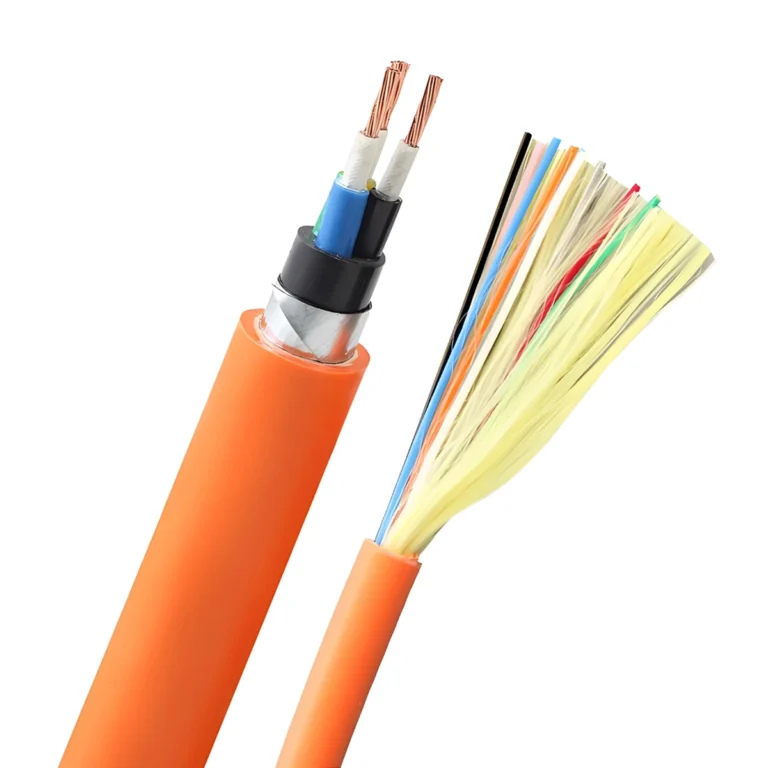

Customized communication and control cables for solar energy systems ensure precise power distribution and control of system operation. ZMS offers control cables, single-mode fiber optic cables, multimode fiber optic cables, and shielded twisted pair cables to connect various equipments.

ZMS All-in-one Cable Solution

ZMS is committed to providing comprehensive and customized cable solutions and integrated quotation services for various solar power generation projects. Whether it is a large-scale ground photovoltaic power station, a distributed rooftop photovoltaic system, or commercial and residential solar installations, our professional team can help customers optimize cable configurations based on the specific needs analysis of the project. This enhances the overall efficiency of the solar power generation system while strictly controlling costs and providing competitive price estimates to support the smooth implementation and long-term stable operation of customer projects.

Our services not only cover a wide range of cable product supplies but also include professional cable system design recommendations, technical consultation support, and global transportation services. After years of development, ZMS Cable Company has established a comprehensive quality assurance system, with multiple certifications such as TÜV EN50618, IEC, ISO 9000, ISO 9001, ISO 14000, ISO 14001, ISO 18000, CE, BS, NFC, ASTM, and DIN. Currently, we produce over 10,000 types of cable products, which are sold to 183 countries and regions.

ZMS Cable Certification

FAQ

Why Use Special Cables for Photovoltaic Systems?

Photovoltaic cables are specifically designed for photovoltaic power generation projects, with insulation and sheathing characteristics that ordinary cables do not possess.

If ordinary cables are used in PV system, they are prone to failure in harsh outdoor environments, greatly reducing the lifespan of the entire solar power system. Additionally, it can lead to current overload, severe voltage drop, frequent generation faults, and low generation efficiency in photovoltaic power plants, even potentially causing fires in the plant.

Therefore, to ensure the long-term stable operation of photovoltaic power plants for 25 years, it is essential to choose cables specifically designed for photovoltaic systems, such as H1Z2Z2-K or PV1-F.

What Is TÜV Certification for Solar Cables?

TÜV Solar Cable Certification refers to a series of certificates awarded to cables that have been tested, inspected and certified by an independent third party of the TÜV Rheinland Group, headquartered in Germany, in accordance with specific standards.

As a special type of cable, the safety and performance of photovoltaic cables are crucial for solar power generation systems, hence they undergo rigorous testing and certification to ensure their quality and reliability.

Regarding TÜV certification for PV cables, its development has progressed from the 2PfG 1169/08.2007 standard to the EN 50618:2014 standard. The most recent standard is IEC FDIS 62930, but most solar cable certifications still adhere to the valid EN 50618 standard.

What Types of Cables Are Needed for Solar Power Systems?

As a crucial component of sustainable energy solutions, the safe and efficient operation of solar power generation systems relies on the appropriate configuration and use of various specialized cables. The types of cables required in a solar power generation system include the following:

Solar DC Cable

These cables are specifically designed for connecting photovoltaic modules (solar panels) and for power transmission between modules to the DC combiner box. Given their direct exposure to outdoor environments, they must possess the following characteristics:

- UV Resistance: To prevent performance degradation due to prolonged sun exposure.

- Weather Resistance: To withstand various weather conditions, including extreme temperatures, humidity, and wind-blown sand.

- Salt Spray Corrosion Resistance: Suitable for coastal areas to prevent salt damage.

- Flame Retardancy: To reduce fire risks and enhance system safety.

- Mechanical Strength: To endure installation and environmental pressures without being easily damaged.

AC Cable

AC cables are used at the inverter output end to transmit the converted AC power to the AC distribution board or directly into the grid. These cables need to meet grid connection standards and possess good insulation properties and heat resistance to ensure safe and efficient power transmission.

Data Communication Cable

In a solar power generation system, data communication cables act as the information bridge. They not only transmit the electrical data generated by the photovoltaic array but also convey real-time status information of inverters and other monitoring equipment to the central monitoring system via wired or wireless networks (including fiber optics) for system optimization and fault diagnosis.

Control Cable

Control cables are used to connect controllers, inverters, and other auxiliary equipment within the system, ensuring automated control and effective monitoring. These cables need to have good signal transmission stability and anti-interference capabilities to ensure accurate execution of control commands.

Grounding Cable

Grounding cables play a critical role in the safety protection of the entire solar power generation system. They provide a low-resistance path to quickly discharge lightning currents or system fault currents, preventing electric shocks and equipment damage, thereby ensuring the safety of personnel and equipment.

Overhead Cable

In certain installation scenarios, such as long-distance transmission or terrain constraints, overhead cables are used for grid connection of the solar power generation system. These cables need to be specially designed to resist external physical damage and climatic factors while maintaining good conductivity and mechanical strength.

When selecting these solar cables, it is essential not only to consider their characteristics and applicable environments but also to ensure that all cables and accessories comply with local electrical safety standards and industry regulations to ensure the long-term stable operation and compliance of the solar power generation system.

What Percentage of the Total Construction Cost Do Cables Represent in a Photovoltaic Power Station?

The cost of cables in a photovoltaic (PV) power station typically represents around 10% of the total construction cost. This percentage can vary based on several factors such as the scale of the project, equipment selection, regional differences, and market fluctuations. According to some estimates:

- Photovoltaic modules (solar panels) account for approximately 50% of the total equipment cost.

- Inverters and other electrical equipment account for about 10%.

- Cables and mounting structures each account for around 10%.

Therefore, cable costs generally make up about 10% of the total construction cost. However, this is a rough estimate, and the actual proportion may vary depending on the specific budget and material prices of a project. Additionally, with advancements in technology and market changes, this percentage may be subject to adjustments.

ZMS can provide comprehensive and customized cable solutions and integrated quotation services for your various solar power projects. Feel free to contact us!

Does ZMS Provide the Tools for Solar Cable Installation?

Yes, ZMS provides the tools for solar cable installation. We offer a comprehensive range of products and solutions tailored to the specific needs of solar power systems, including specialized connectors, and tools required for efficient and safe installation. If you have any specific requirements or need further details about the tools we provide, feel free to let us know!

Project Highlight

ZMS joined forces with Green State Power (GSP), a pioneer in renewable energy infrastructure, to equip a monumental 10 MWP photovoltaic project in Kabul, Afghanistan.

ZMS comprehensively analyzed the PV project and provided it with 1X10 and 1X6 solar cables H1Z2Z2-K, 3X300 LV cables, 3X300 MV cables, as well as ACSR 185/30 overhead cables. Complementing these were vital accessories like PV connectors and meticulously curated toolboxes.

ZMS’s commitment to quality and reliability facilitated smooth installation and operational efficiency, contributing to the region’s sustainable energy infrastructure.