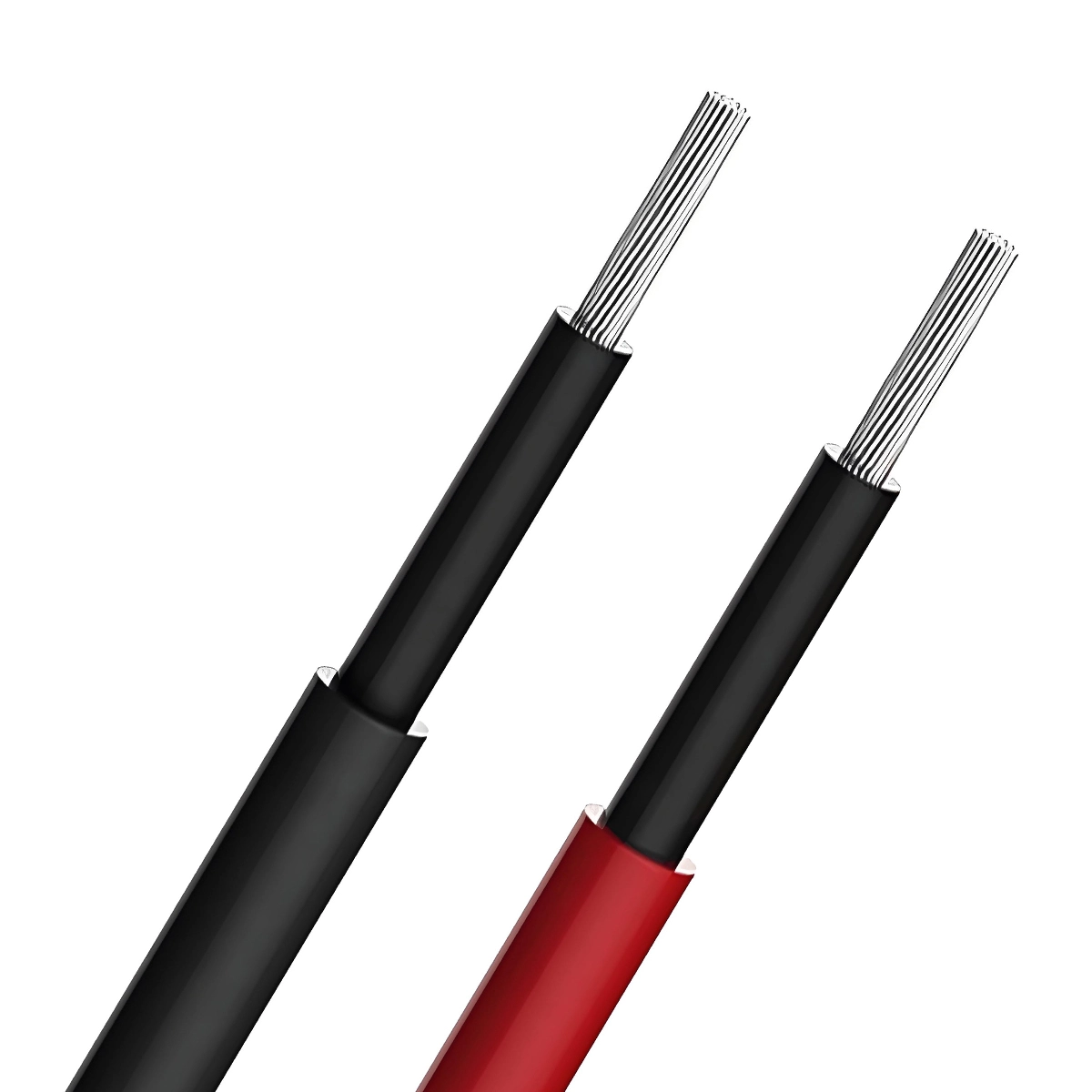

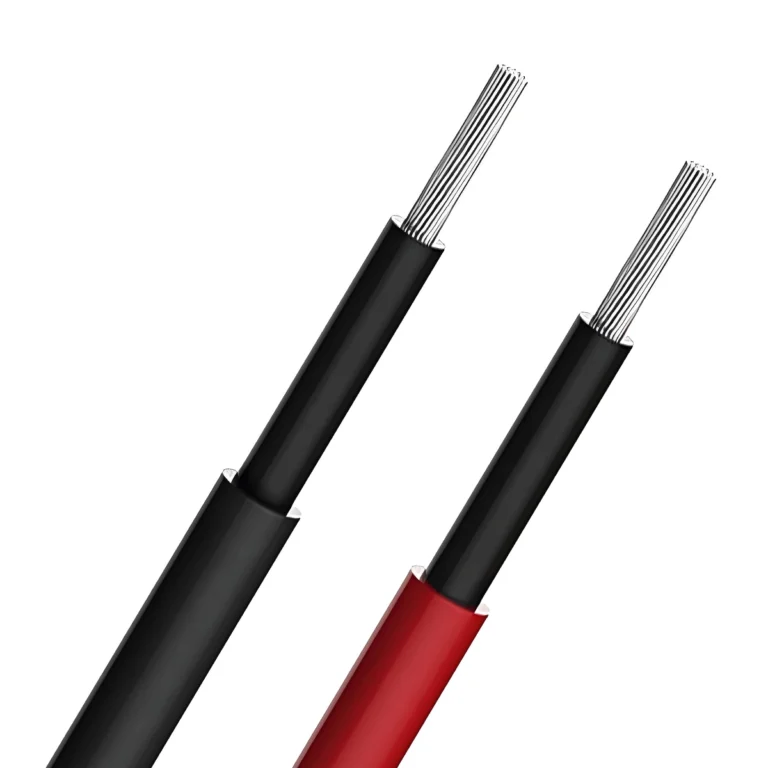

Cabo H1Z2Z2-K

Cabo H1Z2Z2-K é usado principalmente para a conexão entre painéis solares e entre painéis solares e caixas de inversores/junção em sistemas de geração de energia fotovoltaica.

O cabo ZMS Solar H1Z2Z2-K usa material de poliolefina reticulada sem foda de baixa foda de foda baixa, que pode se adaptar às condições climáticas adversas ao ar livre. Possui resistência à umidade e calor, temperaturas altas e baixas, ácidos e álcalis, resistência ao ozono, Resistência UV, retardância da chama, Resistência à abrasão, e forte resistência.

O cabo solar H1Z2Z2-K na série de cabos fotovoltaicos ZMS tem alta eficiência de transmissão e uma longa vida útil de serviço de até 25 anos. Este tipo de cabo PV é fácil de instalar, seguro, e confiável, e pode ser amplamente utilizado em vários projetos de engenharia de energia solar, geração pública de energia solar, usinas de energia fotovoltaica, etc..

- Especificações: 1.5~ 240mm²

- Padrão do produto: EN50618:2014

- Certificação de Produto: TÜV, CE, ISO

Parâmetros técnicos de cabo H1Z2Z2-K

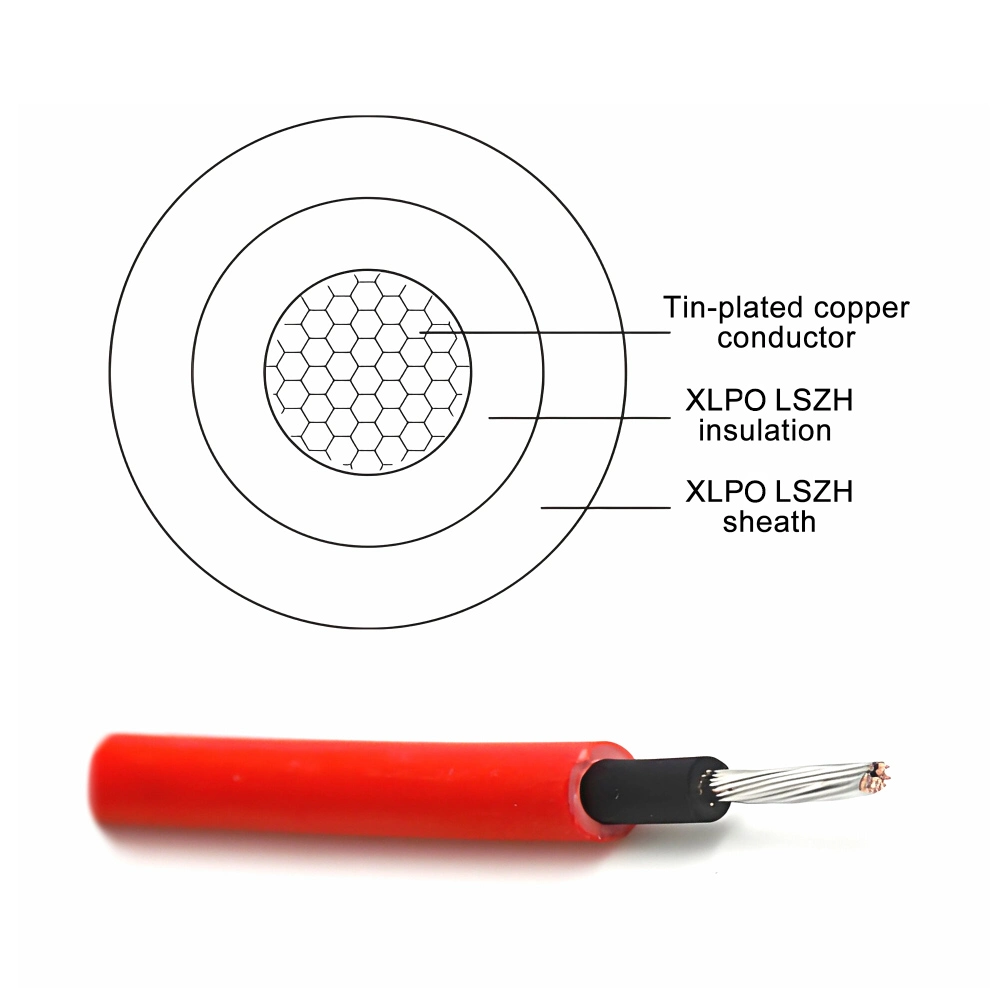

- Condutor: 99.9% Cobre banhado a estanho

- Isolamento: Poliolefina cruzada irradiada sem fumaça de fumaça baixa (Preto)

- Bainha: Poliolefina cruzada irradiada sem fumaça de fumaça baixa (Preto/vermelho)

- Tensão nominal CA (Uo/U): 1.0/1.0kV

- Tensão nominal CC (Uo): 1.5kV (Entre condutores, maestro para a terra)

- Tensão máxima do sistema (Um): 1.2kV

- Temperatura operacional do condutor: -45°C a +120°C

- Temperatura ambiente operacional: -40°C a +90°C

- Temperatura de colocação de cabos: Não inferior a -25°C

- Classificação retardante de chama: EN50625 / Ul1571

- Raio de curvatura mínimo: 6D (D: Diâmetro externo do cabo)

- Métodos de instalação: Colocação de conduíte, colocação de valas rasas, colocação de valas de cabos, colocação de túnel, colocação de sanduíche, colocação aérea apoiada, colocação aérea suspensa, etc..

- Vida útil: ≥25 anos

Certificação ZMS H1Z2Z2-K

Parâmetros de estrutura de cabo H1Z2Z2-K

| Especificação (mm²) | Diâmetro do condutor (milímetros) | Espessura de isolamento nominal (milímetros) | Espessura nominal da bainha (milímetros) | Cabo aproximado de diâmetro externo (milímetros) | Peso aproximado do cabo (kg/km) | Resistência máxima em DC do condutor a 20 ° C (Ω/km) |

| 1× 1,5 | 1.58 | 0.7 | 0.8 | 4.6 | 35 | 13.7 |

| 1× 2,5 | 2.02 | 0.7 | 0.8 | 5.0 | 47 | 8.21 |

| 1× 4 | 2.58 | 0.7 | 0.8 | 5.6 | 65 | 5.09 |

| 1× 6 | 3.17 | 0.7 | 0.8 | 6.2 | 87 | 3.39 |

| 1× 10 | 4.1 | 0.7 | 0.8 | 7.6 | 132 | 1.95 |

| 1× 16 | 5.6 | 0.7 | 0.9 | 8.8 | 197 | 1.24 |

| 1× 25 | 7.1 | 0.9 | 1.0 | 10.9 | 303 | 0.795 |

| 1× 35 | 8.5 | 0.9 | 1.1 | 12.5 | 410 | 0.565 |

| 1× 50 | 10.2 | 1.0 | 1.2 | 14.6 | 573 | 0.393 |

| 1× 70 | 12.0 | 1.1 | 1.2 | 16.6 | 777 | 0.277 |

| 1× 95 | 14.0 | 1.1 | 1.3 | 18.8 | 1030 | 0.210 |

| 1× 120 | 16.0 | 1.2 | 1.3 | 21.0 | 1284 | 0.164 |

| 1× 150 | 17.0 | 1.4 | 1.4 | 22.6 | 1594 | 0.132 |

| 1× 185 | 19.0 | 1.6 | 1.6 | 25.4 | 1979 | 0.108 |

| 1× 240 | 22.0 | 1.7 | 1.7 | 28.8 | 2540 | 0.0817 |

H1Z2Z2-K CAPACIDADE DE CONTRAÇÃO DE CONTRAÇÃO DE LONGO PARA A LIGURAS

| Instalação | Cabo único no ar | Cabo único na superfície de um objeto | Dois cabos em contato na superfície de um objeto |

| Corte transversal (mm²) | Capacidade de carga (UM) | ||

| 1.5 | 30 | 29 | 24 |

| 2.5 | 41 | 39 | 33 |

| 4 | 55 | 52 | 44 |

| 6 | 70 | 67 | 57 |

| 10 | 98 | 93 | 79 |

| 16 | 132 | 125 | 107 |

| 25 | 176 | 167 | 142 |

| 35 | 218 | 207 | 176 |

| 50 | 276 | 262 | 221 |

| 70 | 347 | 330 | 278 |

| 95 | 416 | 395 | 333 |

| 120 | 488 | 464 | 390 |

| 150 | 566 | 538 | 453 |

| 185 | 644 | 612 | 515 |

| 240 | 775 | 736 | 620 |

| Temperatura operacional | 120°C | ||

| Temperatura Ambiente | 60°C | ||

Perguntas frequentes

Por que usar cabos especiais para sistemas fotovoltaicos?

Os cabos fotovoltaicos são projetados especificamente para projetos de geração de energia fotovoltaica, com características de isolamento e revestimento que os cabos comuns não possuem.

Se os cabos comuns forem usados no sistema fotovoltaico, Eles são propensos ao fracasso em ambientes externos severos, reduzindo bastante a vida útil de todo o sistema de energia solar. Adicionalmente, pode levar à sobrecarga atual, queda grave de tensão, Falhas de geração frequente, e eficiência de baixa geração em usinas fotovoltaicas, até potencialmente causar incêndios na planta.

Portanto, para garantir a operação estável de longo prazo de usinas fotovoltaicas para 25 anos, É essencial escolher cabos projetados especificamente para sistemas fotovoltaicos, como H1Z2Z2-K ou PV1-F.

Quais especificações devem ser escolhidas para os cabos PV H1Z2Z2-K?

Em sistemas fotovoltaicos típicos, As opções mais comuns são H1Z2Z2-K 1×4 e H1Z2Z2-K 1×6 cabos. Geralmente, Seções transversais maiores indicam maiores capacidades de carga.

Considerações como tensão de trabalho, Capacidade atual, e a faixa de temperatura ambiental também deve ser fatorada em. Depois de determinar a tensão e os requisitos atuais, Consulte a tabela de parâmetros dos cabos H1Z2Z2-K para selecionar a especificação apropriada.

Se você encontrar incerteza na seleção de especificações do cabo, Nossa equipe técnica do ZMS está disponível para oferecer soluções personalizadas.

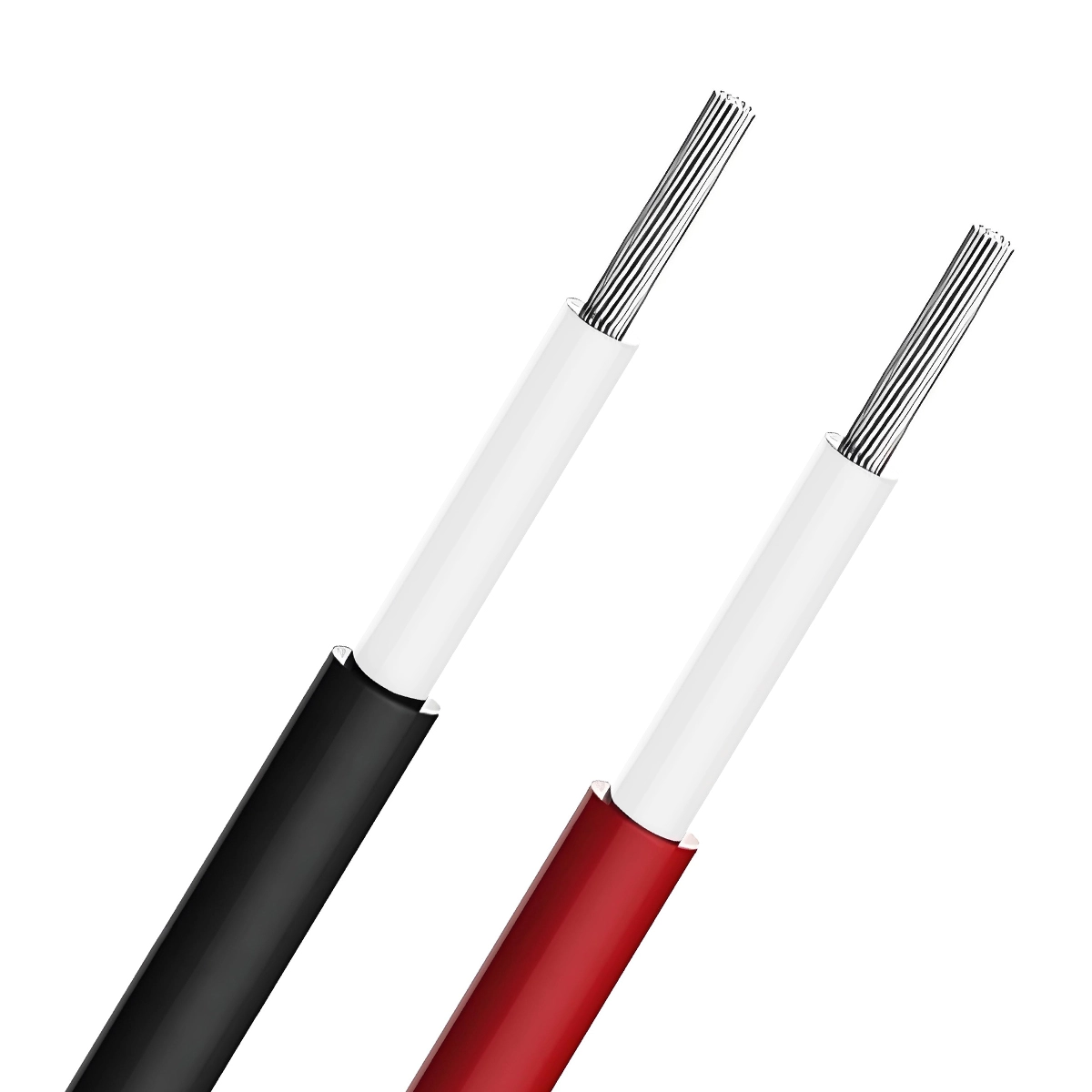

Quais são as diferenças entre os cabos fotovoltaicos H1Z2Z2-K e PV1-F?

O cabo PV1-F é uma versão mais antiga do cabo solar que está em conformidade com o padrão TÜV 2Pfg1169, e sua certificação padrão deixou de ser atualizada. Em contraste, o cabo fotovoltaico H1Z2Z2-K está em conformidade com a mais recente TÜV EN50618:2014 certificação.

As classificações de tensão diferem entre os cabos PV1-F e H1Z2Z2-K. PV1-F tem uma tensão nominal de CC: 1.0kV e CA: Uo/U: 0.6/1.0kV, enquanto H1Z2Z2-K tem uma tensão nominal de DC: 1.5kV e CA: Uo/U: 1.0/1.0kV. H1Z2Z2-K pode fornecer maior eficiência e estabilidade de transmissão.

Em termos de estrutura, O cabo PV1-F possui uma única camada de isolamento, enquanto o cabo H1Z2Z2-K adota uma estrutura de isolamento de camada dupla. Isso torna o cabo H1Z2Z2-K superior em durabilidade e proteção, especialmente contra danos mecânicos e fatores ambientais.

Resumindo, O cabo solar H1Z2Z2-K tem design mais avançado, oferecendo maior desempenho elétrico e mecânico, adequado para ambientes de aplicação mais exigentes. Por outro lado, O cabo solar PV1-F é principalmente vantajoso em termos de custo-benefício, adequado para a maioria dos sistemas fotovoltaicos convencionais.

Para considerações de custo-benefício, O cabo PV1-F pode ser usado para conexões em série entre módulos fotovoltaicos e conexões paralelas de strings a caixas de distribuição CC. Enquanto isso, O cabo H1Z2Z2-K pode ser usado para conexões entre caixas de distribuição e inversores, bem como para conexões de corrente contínua em grandes inversores.

Quais são as diferenças entre as aplicações DC e CA de cabos fotovoltaicos H1Z2Z2-K?

Os cabos H1Z2Z2-K podem ser usados para ambos os circuitos CC (1.5kV) e circuitos CA. (1.0/1.0kV). Em sistemas de geração de energia fotovoltaica, Suas diferenças específicas de aplicação são as seguintes:

Para aplicativos DC:

- Conexão em série entre módulos fotovoltaicos

- Conexão paralela entre seqüências

- Conexão paralela de cordas para caixas de distribuição DC

- Conexão de caixas de distribuição DC para inversores

Para aplicações CA.:

- Conexão de inversores para transformadores de intensificação

- Conexão de transformadores de intensificação para dispositivos de distribuição

- Conexão de dispositivos de distribuição para a grade ou usuários

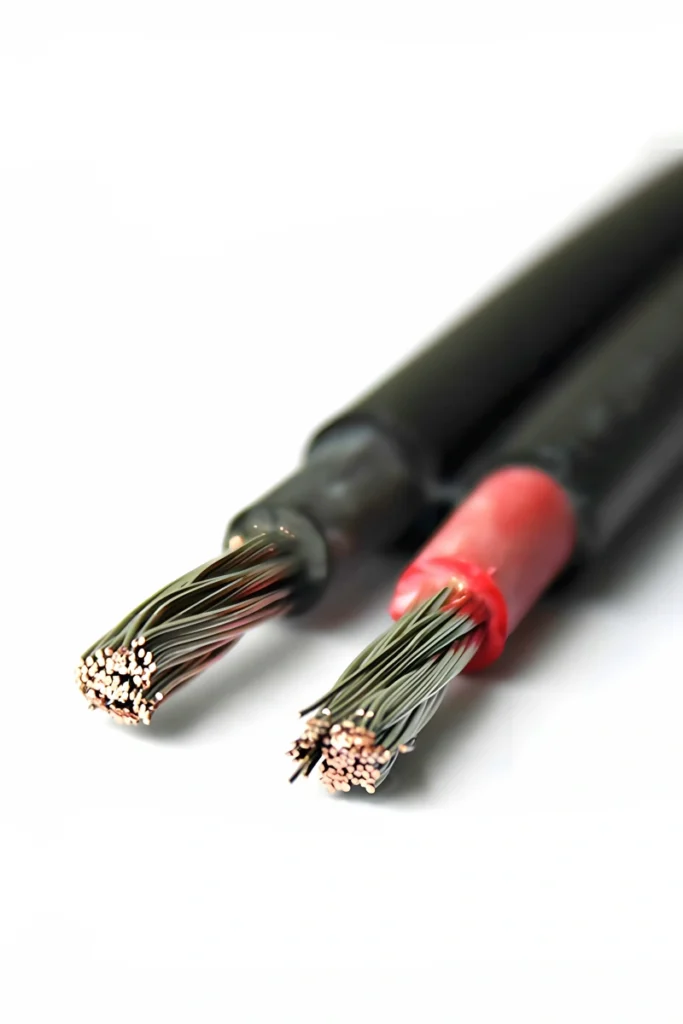

Por que os cabos solares são divididos em vermelho e preto?

Na indústria fotovoltaica, O uso de cabos vermelhos e pretos tornou -se um método de identificação amplamente aceito. Seu objetivo principal é distinguir entre postes positivos e negativos. Em circuitos CC, tipicamente, Os fios solares vermelhos indicam o pólo positivo da corrente, Enquanto os fios solares pretos indicam o poste negativo. Essa diferenciação de cores ajuda a identificar rapidamente a polaridade das conexões fotovoltaicas durante a instalação e manutenção de sistemas solares, impedindo assim erros de fiação.

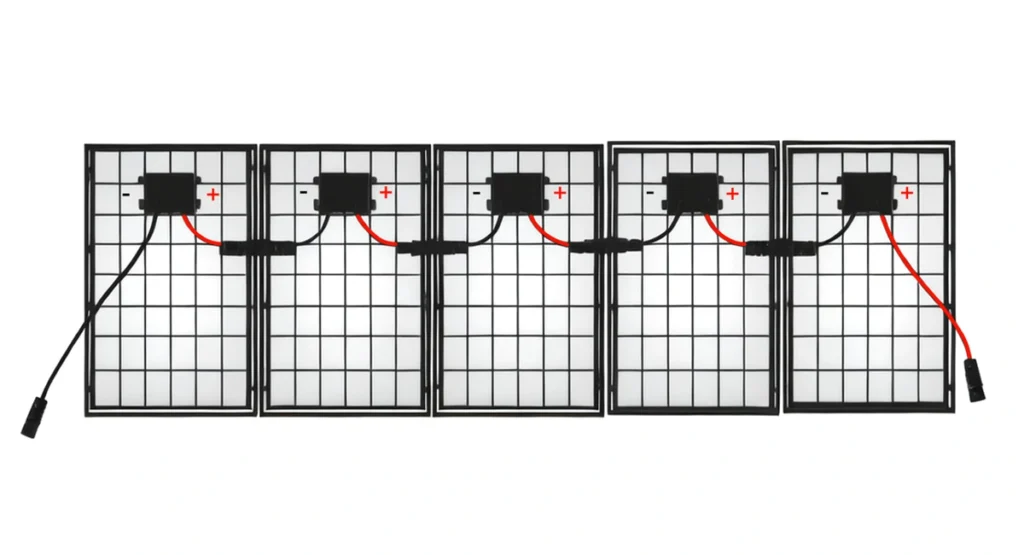

Como fazer conectores de painel solar e conectar painéis solares com cabos H1Z2Z2-K?

Depois que os conectores solares são preparados, Os painéis solares podem ser conectados em paralelo, série, ou configurações híbridas.

Em conexão paralela, Os terminais positivos e negativos de múltiplos painéis fotovoltaicos são conectados separadamente. Este método de cabeamento aumenta a saída geral geral do sistema, Adequado para cenários que requerem maior saída de corrente.

Na conexão em série, Os terminais positivos e negativos de múltiplos painéis fotovoltaicos são conectados sequencialmente. Este método de cabeamento aumenta a saída geral de tensão do sistema, Adequado para cenários que requerem maior saída de tensão.

A conexão híbrida combina métodos de fiação paralela e em série. Envolve conectar alguns painéis fotovoltaicos em paralelo e depois conectar essas combinações paralelas em série. Métodos de fiação híbrida permitem combinações flexíveis para atender às necessidades de energia de diferentes cenários.

O ZMS pode fornecer vários conectores MC universais separadamente, que são perfeitamente compatíveis com os conectores MC4. Adicionalmente, Também podemos fornecer cabos de extensão de painel solar com conectores pré-fabricados para atender aos seus diferentes requisitos.

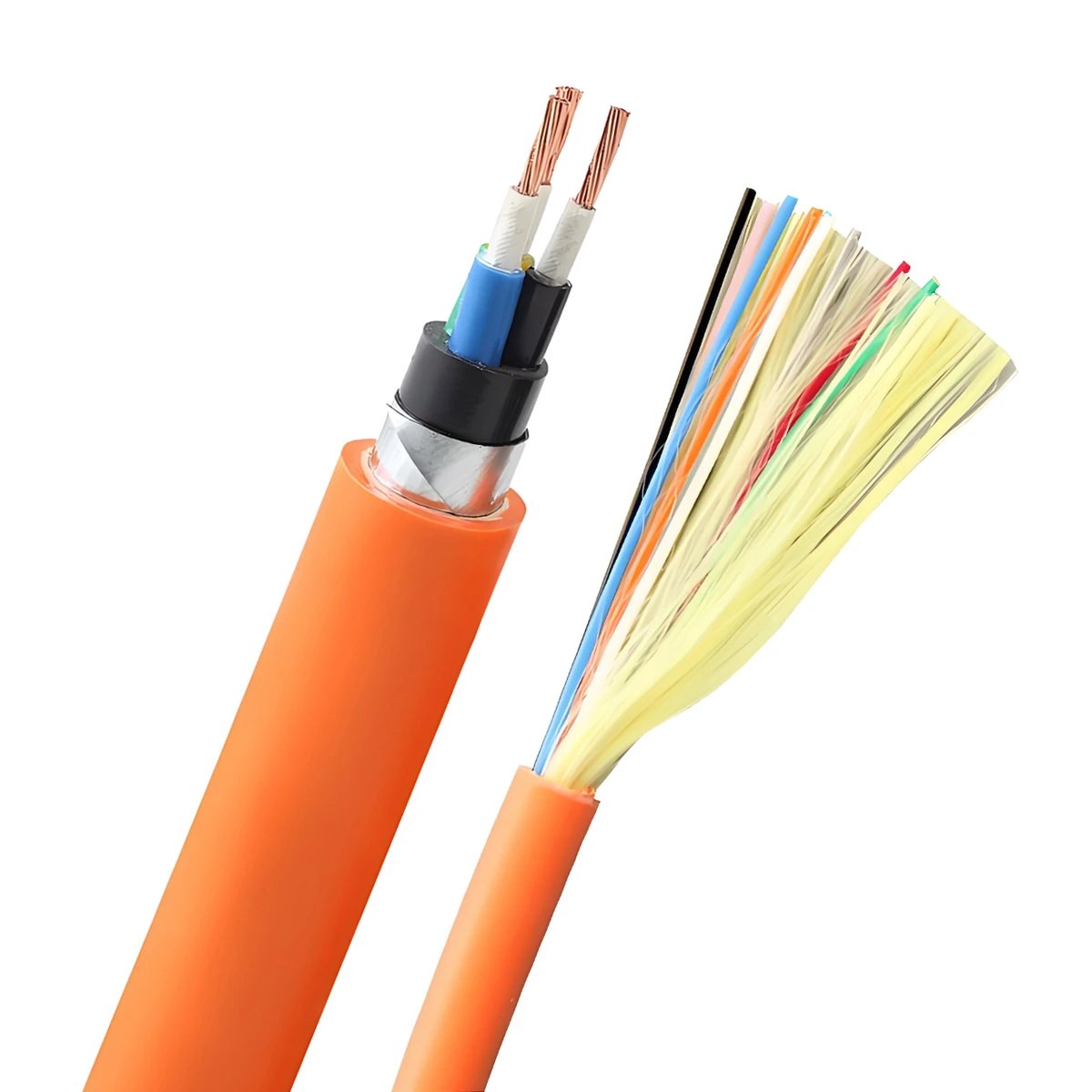

Destaque do projeto

ZMS uniu forças com Poder do Estado Verde (SPG), pioneira em infraestrutura de energia renovável, equipar um monumental 10 Projeto fotovoltaico MWP em Cabul, Afeganistão.

A ZMS analisou exaustivamente o projeto fotovoltaico e forneceu-lhe 1Cabos solares X10 e 1X6 H1Z2Z2-K, 3Cabos X300 BT, 3Cabos de MT X300, bem como CAA 185/30 cabos aéreos. Complementando estes acessórios vitais, como conectores fotovoltaicos e caixas de ferramentas meticulosamente selecionadas.

O compromisso da ZMS com a qualidade e confiabilidade facilitou a instalação tranquila e a eficiência operacional, contribuindo para a infraestrutura energética sustentável da região.

Serviço ZMS

Fabricação Personalizada

We understand that every customer's needs are unique. Portanto, oferecemos serviços personalizados de personalização de cabos solares, adaptando cada detalhe, desde especificações de cabos até interfaces de conexão, de acordo com os requisitos específicos do seu projeto, garantindo máxima compatibilidade e eficiência.

Logística Global de Resposta Rápida

Com o apoio da nossa rede logística global, A ZMS garante que seus pedidos de cabos fotovoltaicos cheguem a qualquer canto do mundo com segurança e rapidez. Nossa equipe de logística profissional monitora todas as etapas do transporte para garantir a entrega pontual de suas mercadorias.

Suporte Técnico

ZMS's technical support team is always on standby. Quaisquer que sejam os desafios técnicos que você encontrar, podemos fornecer respostas rápidas e soluções profissionais, garantindo uma experiência de usuário sem preocupações.

Produção Verde

Nossos cabos e acessórios solares cumprem rigorosamente os padrões ambientais durante o processo de produção, minimizando seu impacto no meio ambiente. Ao escolher ZMS, você não está apenas investindo em cabos fotovoltaicos de alta qualidade, mas também contribuindo para o desenvolvimento sustentável do planeta.