Solar Earth Cable

Solar earth cable is mainly used in grounding systems for solar power generation. In PV systems, solar panels are usually interconnected with grounding cables, which are then connected to the earth. This provides a low-impedance path to discharge lightning-induced currents, thereby preventing damage to the PV system.

ZMS’s yellow-green solar earth cable features high flexibility, flame resistance, UV resistance, and durability under extreme temperatures. It is robust and durable, providing reliable grounding protection for various types of solar power generation projects.

Applications:

- Connection between solar components

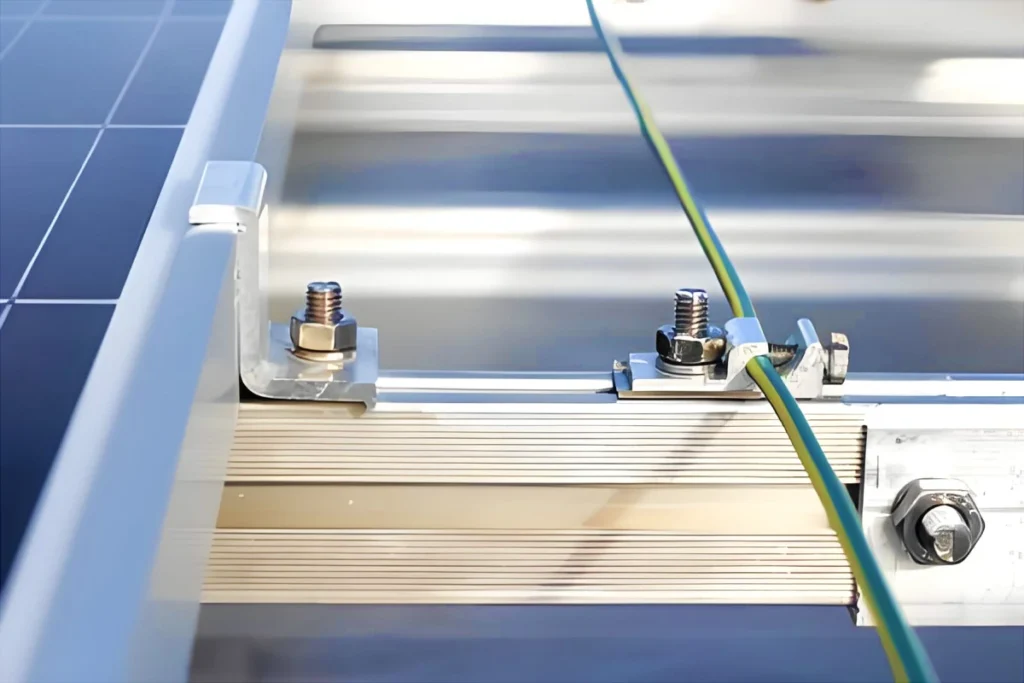

- Connection between components and brackets

- Grounding of component brackets

- Inverter protective grounding

- Grounding of distribution box enclosures

Technical Parameters of Solar Earth Cable

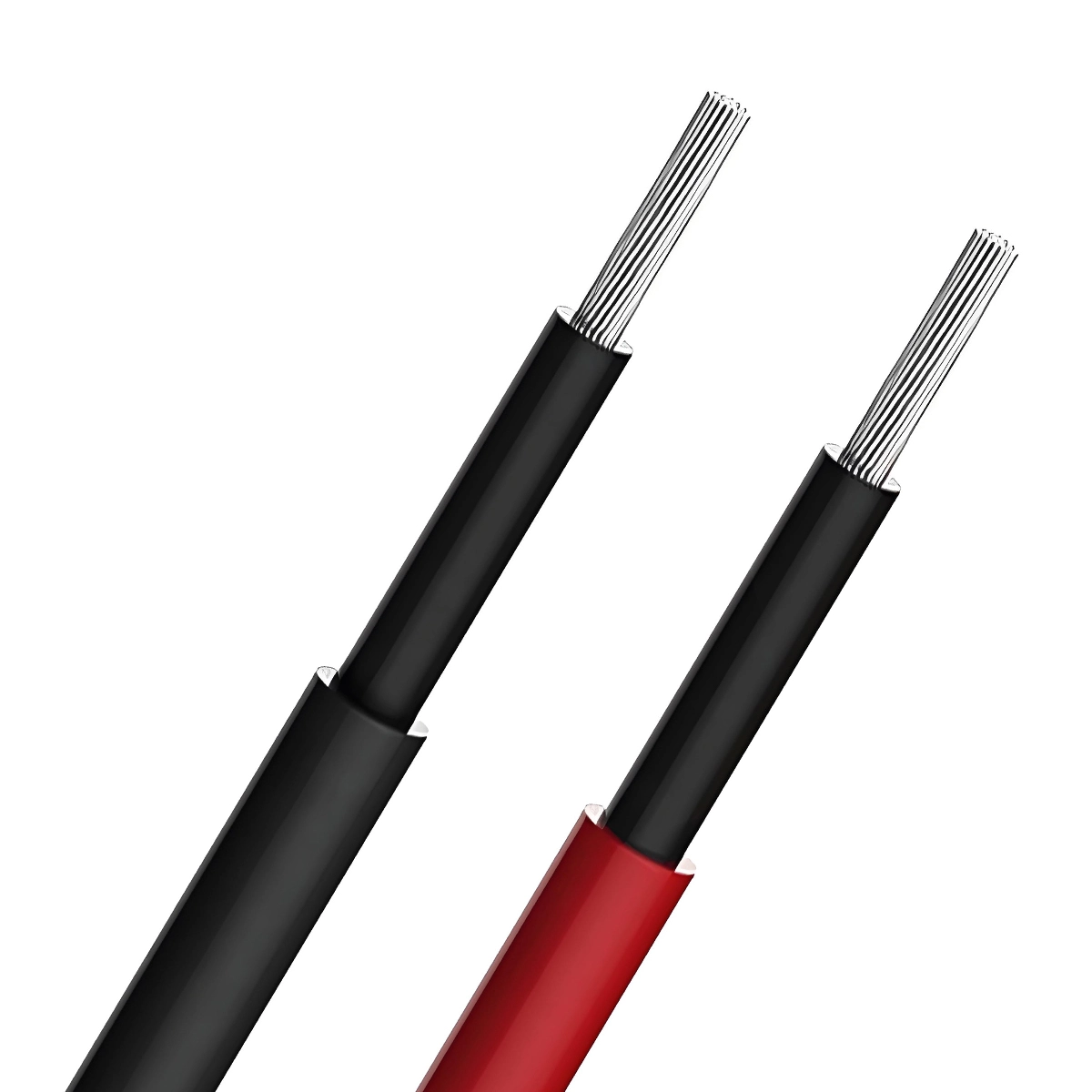

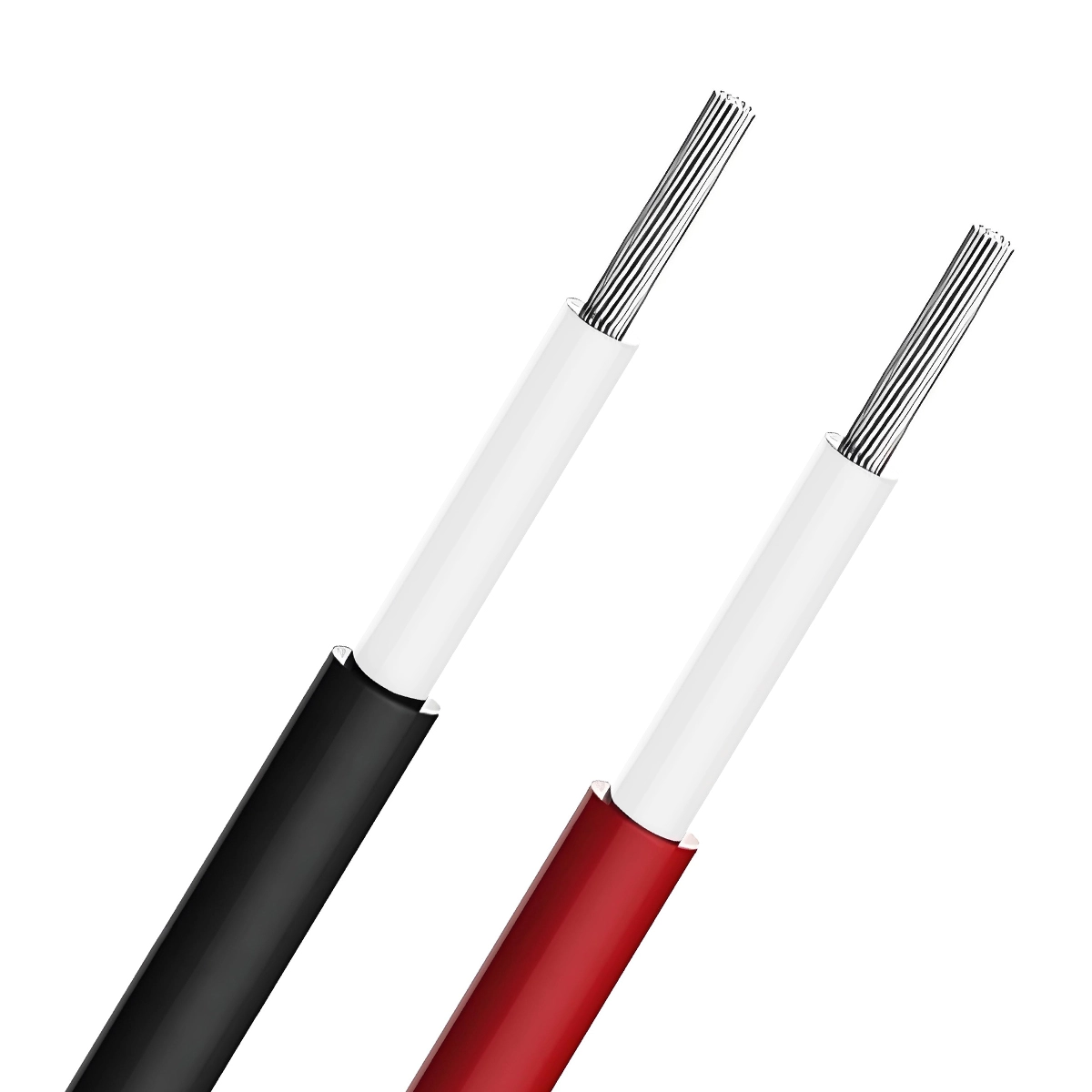

- Conductor: Copper, compliant with IEC 60228 class 5

- Sheath: PVC/RUBBER

- Voltage Rating: DC U0/U 900/1500 V

- Maximum Permissible Operating Voltage: DC 1.8 kV (Conductor-conductor, non-earthed system)

- Minimum Bending Radius (fixed installation): 4D (D: Outer diameter of the cable)

- Certifications: ROHS/VDE/CE/ISO9001:2008

- Color: Yellow-green dual color

- Specifications: 1.0mm², 1.5mm², 2.5mm², 4mm², 6mm², 10mm², 16mm², 25mm², 35mm², 50mm², 70mm²

- Length: Customizable, common lengths are 80mm, 100mm, 150mm, 200mm, 300mm, 500mm

ZMS Solar Cable Certification

FAQ

Why Should Solar Power Generation Systems Be Grounded?

Grounding in PV systems is one of the most frequently overlooked issues by PV installation personnel, especially in small-capacity PV systems where grounding and lightning protection are not given much attention.

However, if grounding is not done, errors can occur due to low insulation resistance to ground or excessive leakage currents, affecting power generation and potentially endangering personal safety. Additionally, unshielded or elevated metal parts are more susceptible to lightning strikes. Without grounding, equipment may be struck by lightning, causing significant damage to the PV power generation system.

Grounding in PV systems mainly includes grounding on the solar component side, inverter side, and distribution cabinet side. Proper grounding not only enhances the safety of the solar system but also extends its lifespan.

How Are Solar Panels Grounded?

Generally, grounding holes on the solar panels are used to connect between strings of panels. The panels at both ends of the string are connected to the metal frame, primarily using yellow-green solar earth cables.

For grounding the panel frames, copper bonded steel rods of φ10 or φ12 are typically used, buried 1.5 meters underground.

The grounding resistance of solar panels should not exceed 4Ω. If the grounding resistance requirement is not met, resistance-reducing agents are usually added, or the grounding rods are buried in areas with lower soil resistivity.

Why Should the Frames of Solar Panels Be Connected and Grounded?

Some people believe that since both the solar panels and their supporting structures are metal, grounding the supports alone is sufficient.

In reality, most solar panel aluminum frames and galvanized or aluminum alloy supports are coated, which does not meet grounding requirements. Additionally, solar panels can age over time, potentially leading to excessive leakage currents or low insulation resistance to ground. If the solar panel frames are not grounded, after a period of use, this can result in inverter failures, preventing the PV system from generating electricity properly.

When connecting solar panel frames to metal supports, it is necessary to remove the oxide layer from the metal surfaces to reduce grounding impedance, ensuring it meets grounding requirements.

How Are PV Inverters and Distribution Cabinets Grounded?

Inverter Grounding: The grounding of the inverter is primarily achieved through the grounding wire of the AC cable and the grounding of the inverter’s casing. These measures help prevent errors in the PV inverter and ensure the stable operation of the system.

Distribution Cabinet Grounding: The grounding of the distribution cabinet is mainly to ensure the electrical safety of the entire system and the normal operation of the equipment. Specific grounding methods may include making a solid metal connection between the metal parts of the distribution cabinet and the grounding body.

Project Highlight

ZMS joined forces with Green State Power (GSP), a pioneer in renewable energy infrastructure, to equip a monumental 10 MWP photovoltaic project in Kabul, Afghanistan.

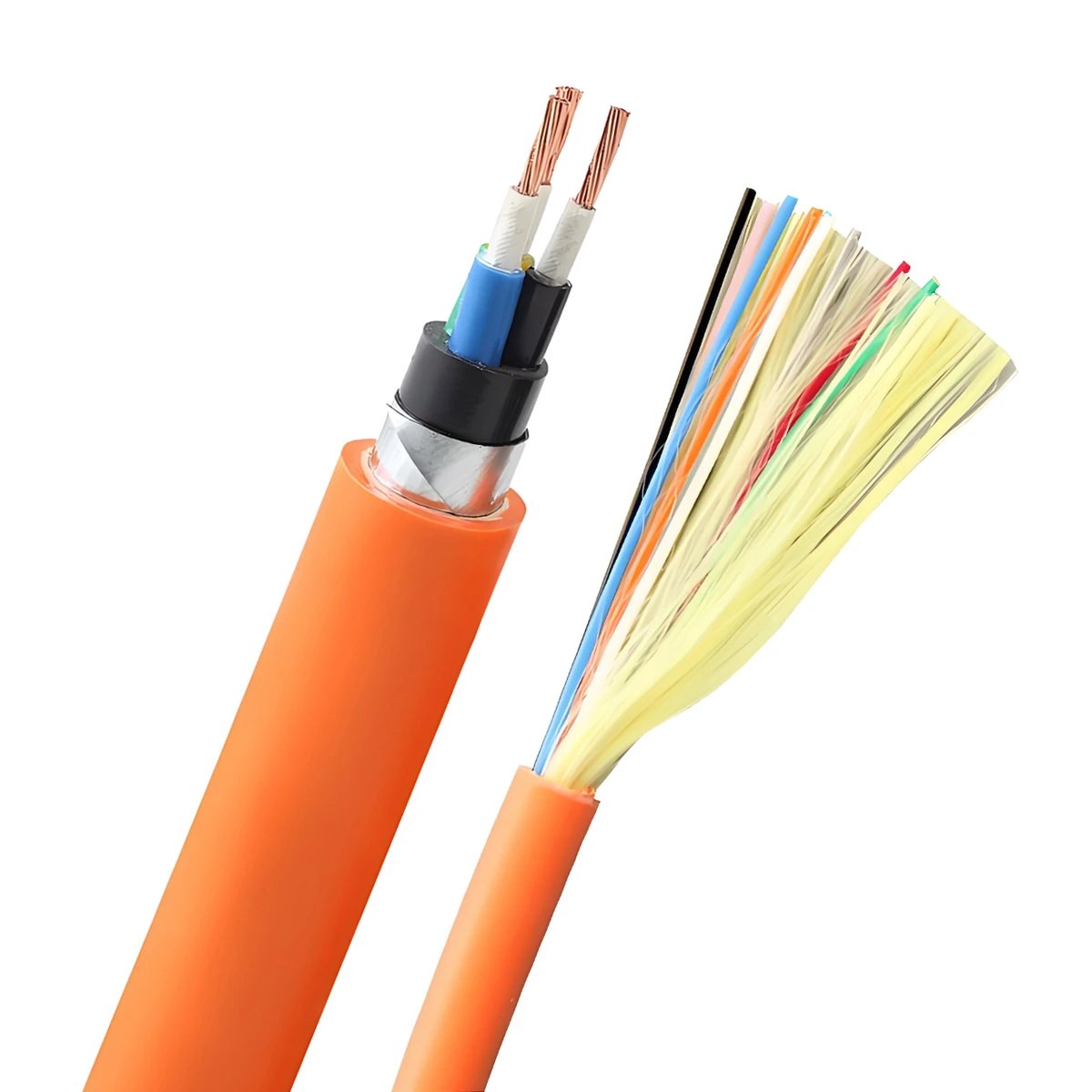

ZMS comprehensively analyzed the PV project and provided it with 1X10 and 1X6 solar cables H1Z2Z2-K, 3X300 LV cables, 3X300 MV cables, as well as ACSR 185/30 overhead cables. Complementing these were vital accessories like PV connectors and meticulously curated toolboxes.

ZMS’s commitment to quality and reliability facilitated smooth installation and operational efficiency, contributing to the region’s sustainable energy infrastructure.

ZMS Service

Customized Manufacturing

We understand that every customer's needs are unique. Therefore, we offer personalized solar cable customization services, tailoring every detail from cable specifications to connection interfaces according to your specific project requirements, ensuring maximum compatibility and efficiency.

Global Rapid Response Logistics

With the support of our global logistics network, ZMS ensures that your photovoltaic cable orders reach any corner of the world safely and promptly. Our professional logistics team monitors every stage of transportation to ensure timely delivery of your goods.

Technical Support

ZMS's technical support team is always on standby. Whatever technical challenges you encounter, we can provide rapid responses and professional solutions, ensuring a worry-free user experience.

Green Production

Our solar cables and accessories strictly adhere to environmental standards during the production process, minimizing their impact on the environment. By choosing ZMS, you are not only investing in high-quality photovoltaic cables but also contributing to the sustainable development of the planet.